Motor-driven braided fabric pulling device and pulling method thereof

A pulling device and motor-driven technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problem of the inability to pull a single layer of cloth, the inability to achieve precise control of the pulling force, and the inability to achieve partial knitting of knitted fabrics. Pulling and other issues, to achieve the effect of reducing energy and material loss, simple and flexible structure, easy repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

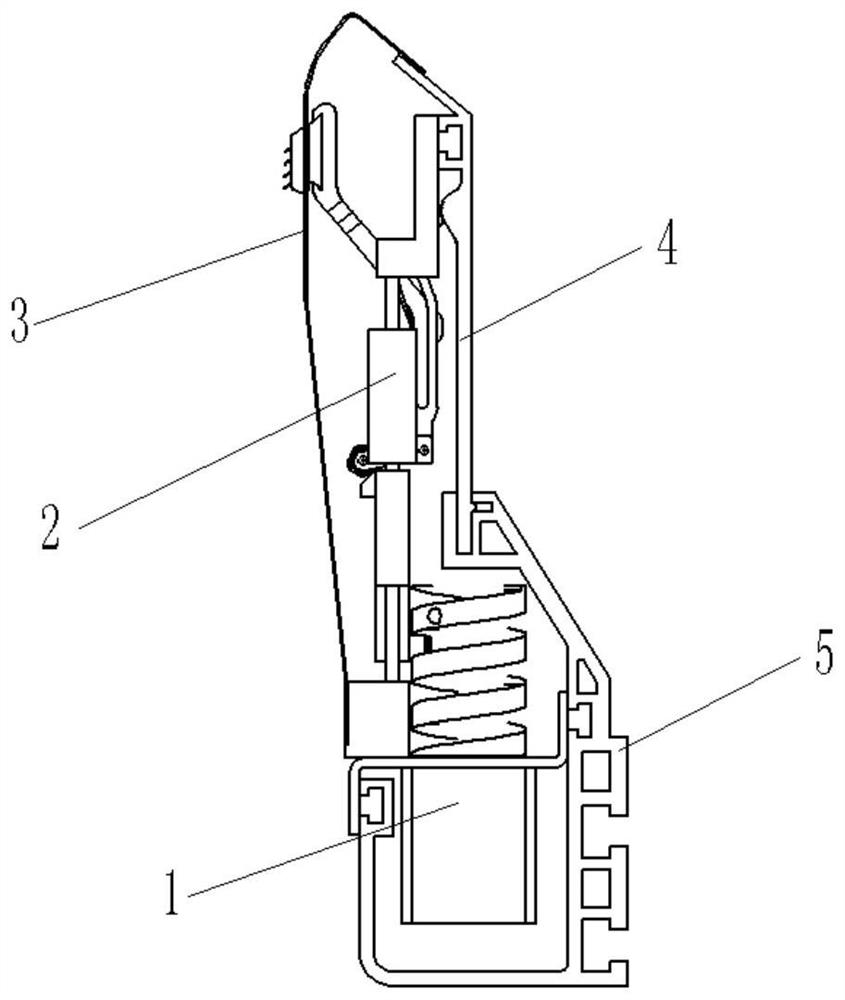

[0031] like Figure 1-7 As shown, the present invention provides a motor-driven braid pulling device, a motor-driven braid pulling device, including a housing, the housing includes an upper housing 4 and a lower housing 5, a drive module 1, And the lifting module 2. The driving module and the lifting module are respectively connected to the housing, and the driving module is driven by the motor 11 to rotate the cylindrical cam 13, and a thread groove is provided on the surface of the cylindrical cam; the lower end of the lifting module is provided with a pull rod roller 30, and the pull rod roller is arranged on the thread groove of the cylindrical cam Inside, it moves up and down with the positive and negative rotation of the cylindrical cam, thereby driving the needle claw seat 22 at the upper end of the lifting module to move up and down.

[0032] Using the cylindrical cam 13 to drive the pull rod roller to move up and down, can use the simplest mechanical structure in a l...

Embodiment 2

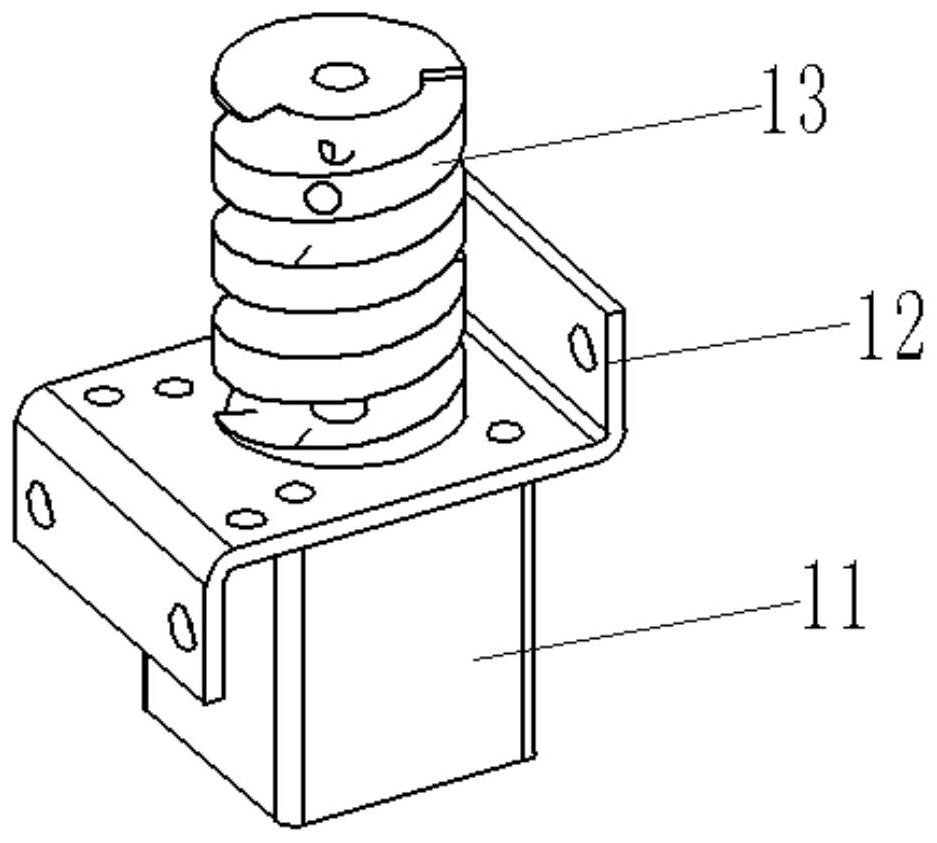

[0036] figure 2 It is a structural schematic diagram of the drive module in the embodiment of the present invention. As shown in Figures 1 and 2, the drive module is sequentially connected by a motor 11, a motor plate 12 and a cylindrical cam 13 from bottom to top, and the motor plate 12 is fixed on the lower casing 5. The motor The shaft passes above the motor plate 12, and the cylindrical cam 13 is fixed on the motor shaft. The rod roller 30 is arranged in the thread groove of the cylindrical cam 13 and moves up and down with the rotation of the cylindrical cam 13 .

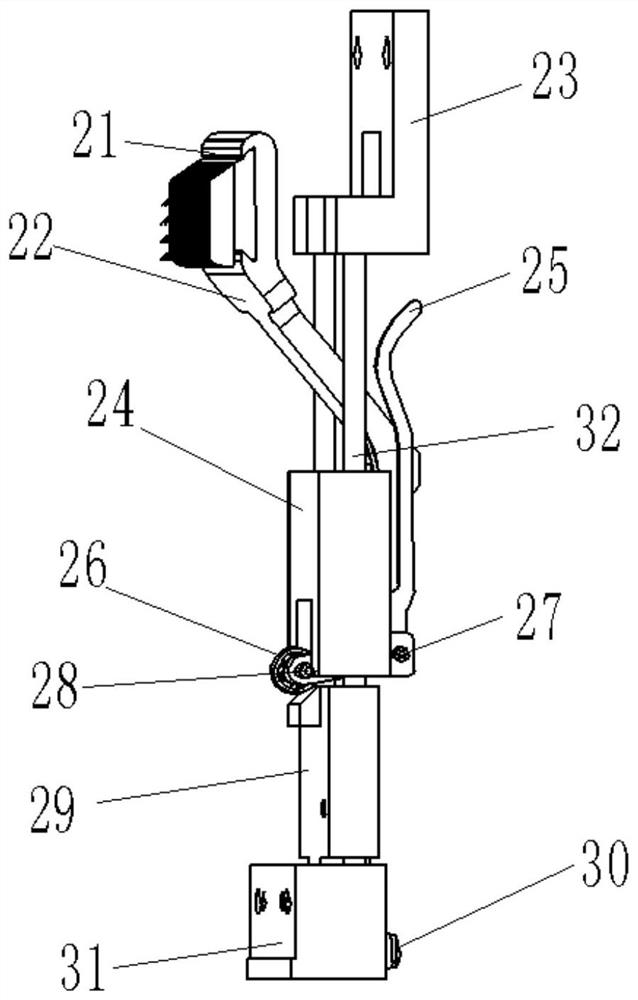

[0037] image 3 It is a schematic diagram of the lifting module of the present invention, such as image 3 As shown, the lifting module includes a lower fixed block 31, a push block 29, a guide shaft 32, and an upper fixed seat 23 connected sequentially from bottom to top. The cylindrical cam is connected to the side of the lower fixed block, and the needle claw seat is connected to the guide shaft.

[0038...

Embodiment 3

[0042] like Figure 5 , 6 As shown, the invention provides a pulling method of a braided pulling device, comprising the following steps:

[0043] Step 1: From station a to station b, the motor drives the cylindrical cam to rotate forward, and the pull rod roller moves downward in the thread groove, driving the push block to move downward along the guide shaft. The lifting seat does not have the support of the push block. The guide shaft falls, thereby driving the needle claw seat and the spring piece to move downward. The spring piece is squeezed by the protrusion of the upper shell, and moves inward to squeeze the needle claw seat. The cloth hook protrudes out of the baffle, and when the top of the spring leaf moves down to the highest point of the upper casing, the pulling device moves to the b station, and the needle claw on the cloth hook penetrates the cloth and pulls it downward;

[0044] Step 2 From station b to station c, the motor continues to drive the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com