Solid wood board leftover material pulping device and using method thereof

A technology of leftover materials and boards, which is applied to the separation of raw materials, wood processing equipment, fiber raw materials, etc., can solve the problems of low pulping efficiency and poor quality, achieve the effect of increasing the mixing area, good mixing effect, and improving pulping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

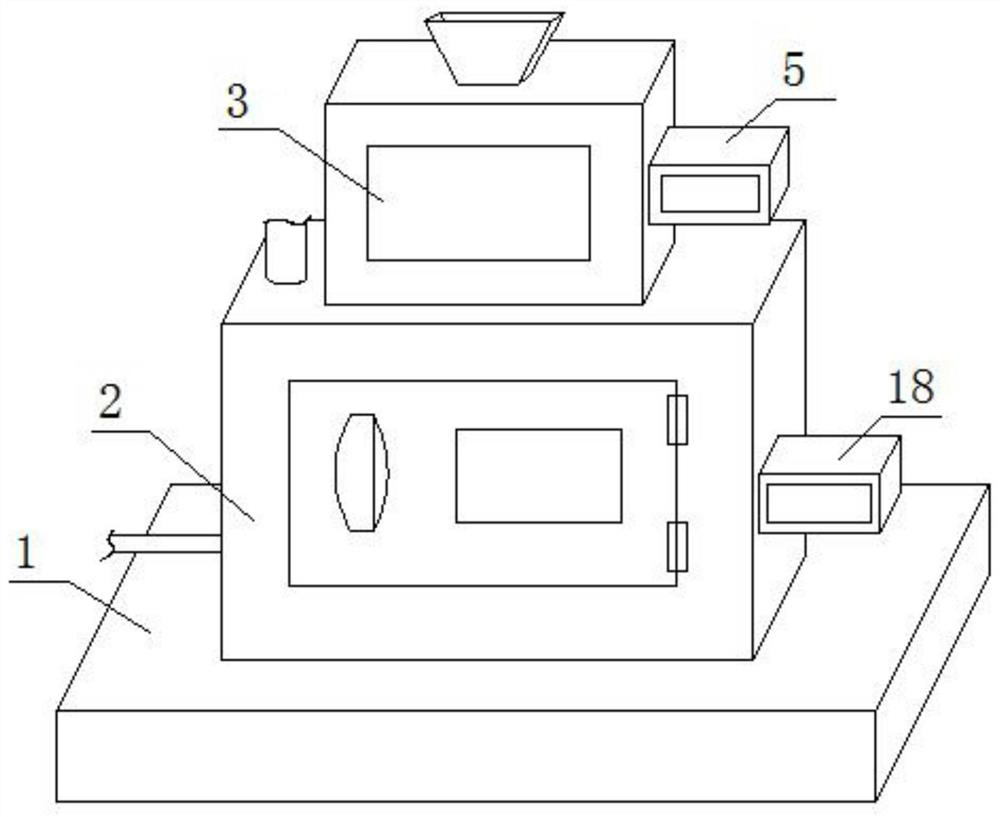

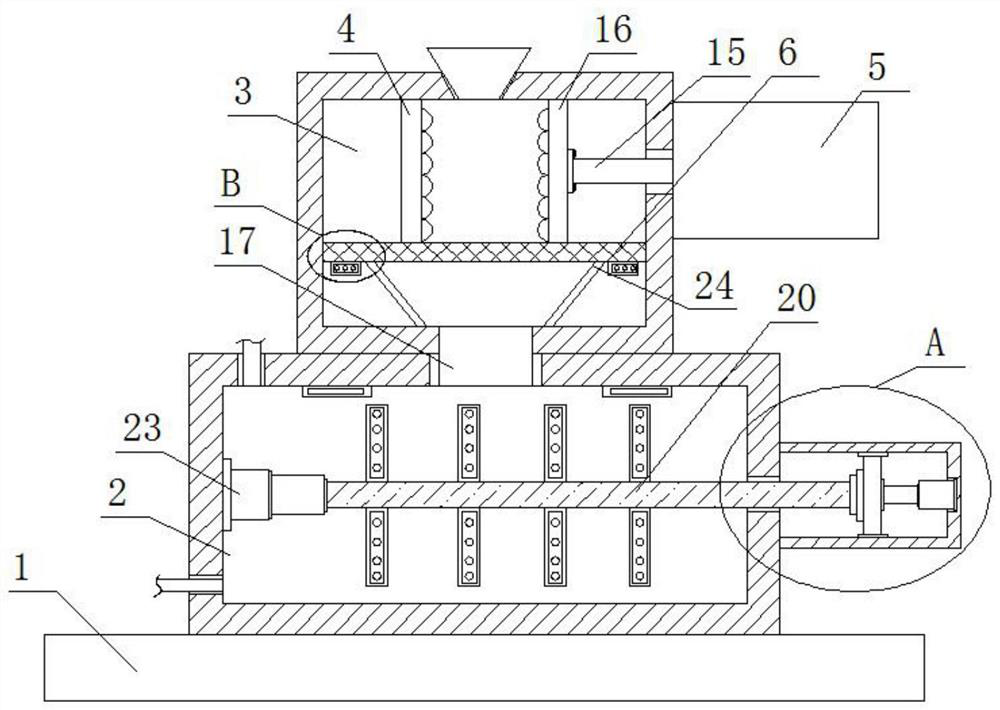

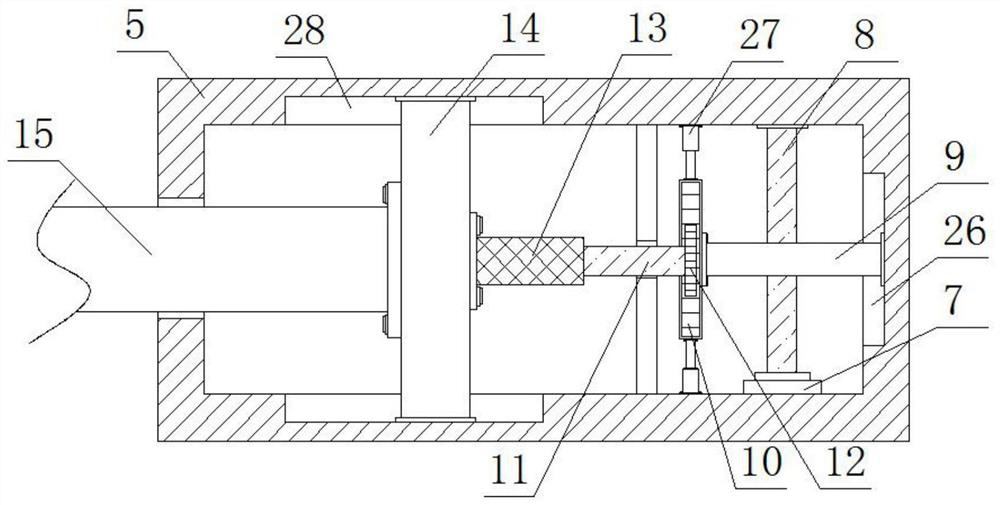

[0029] see Figure 1-5 , the present embodiment provides a solid wood plank leftover pulping device, comprising a base 1, the top of the base 1 is fixedly connected with a fixed box 2, the top of the fixed box 2 is fixedly connected with a crushing box 3, and the inside of the crushing box 3 is fixedly connected with a filter plate 6, the top of the filter plate 6 and the top inside of the crushing box 3 are fixedly connected with the same first crushing plate 4, one side of the crushing box 3 is fixedly connected with a power box 5, and the bottom inner wall of the power box 5 is fixedly connected with a The first motor 7, the output shaft of the first motor 7 is fixedly connected with a rotating shaft 8, the rotating shaft 8 is screwed with a moving plate 9, the power box 5 is slidingly connected with a sliding plate 14, and one side of the sliding plate 14 is fixedly connected with a A threaded seat 13, one side of the threaded seat 13 is provided with a threaded groove, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com