Roof waterproof construction device and method

A construction device and technology of waterproofing membrane, applied in the direction of tools for roofing, roofing, roof covering, etc., can solve the problems of house leakage, the effect is not very obvious, the heating of the waterproofing membrane laying surface, etc., to ensure the heating effect, the effect of reducing the hollow phenomenon, and improving the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

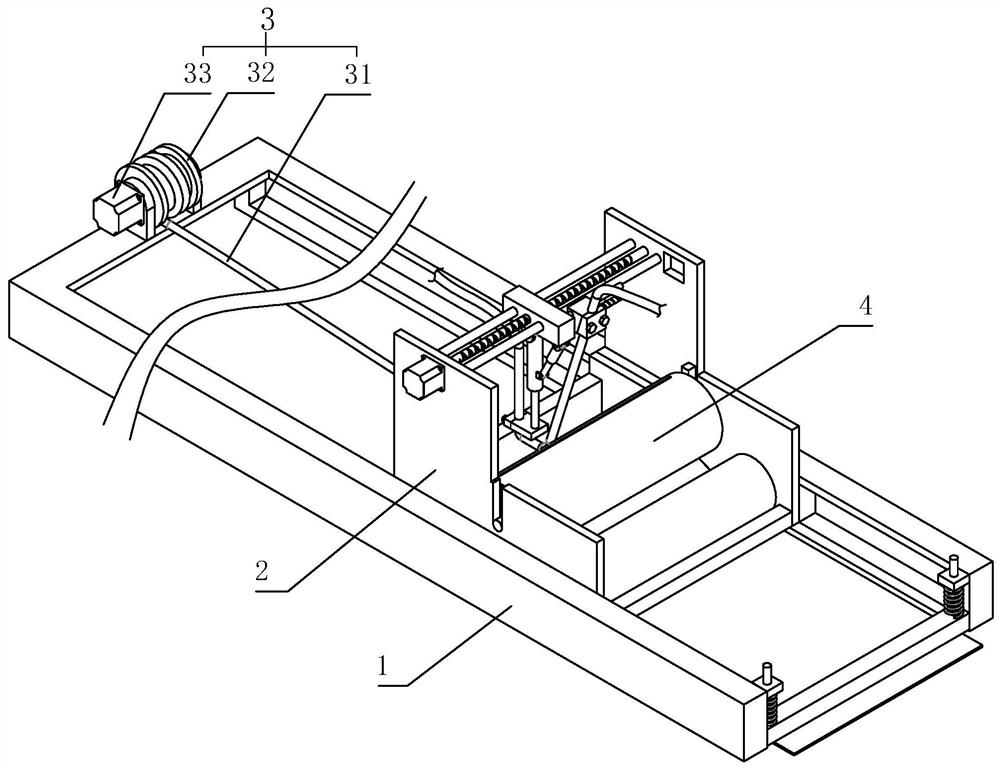

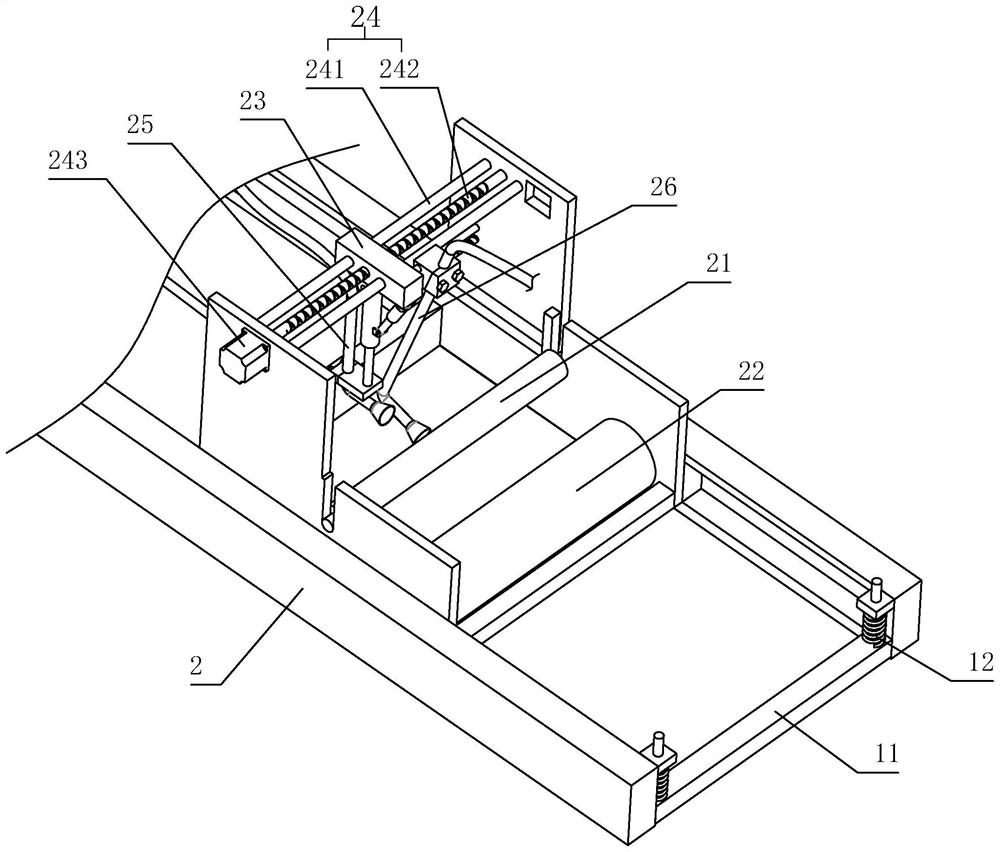

[0049] Example 1: refer to figure 1 , which is a roof waterproof construction device disclosed in the present invention, comprising a guide rail frame 1 arranged in the transverse direction along the length direction, a sliding frame 2 slidingly connected to the guide rail frame 1 along the length direction of the guide rail frame 1, and a sliding frame 2 for driving the sliding frame 2. Move the drive mechanism 3. The driving mechanism 3 includes a traction rope 31 fixedly connected to the sliding frame 2 at one end, a reel fixedly connected to the guide rail frame 1 for retracting or releasing the traction rope 31, and a stepping motor 33 for driving the reel to rotate. The other end of 31 is fixedly connected to the drum 32 , and the stepping motor 33 is fixed to the guide rail frame 1 .

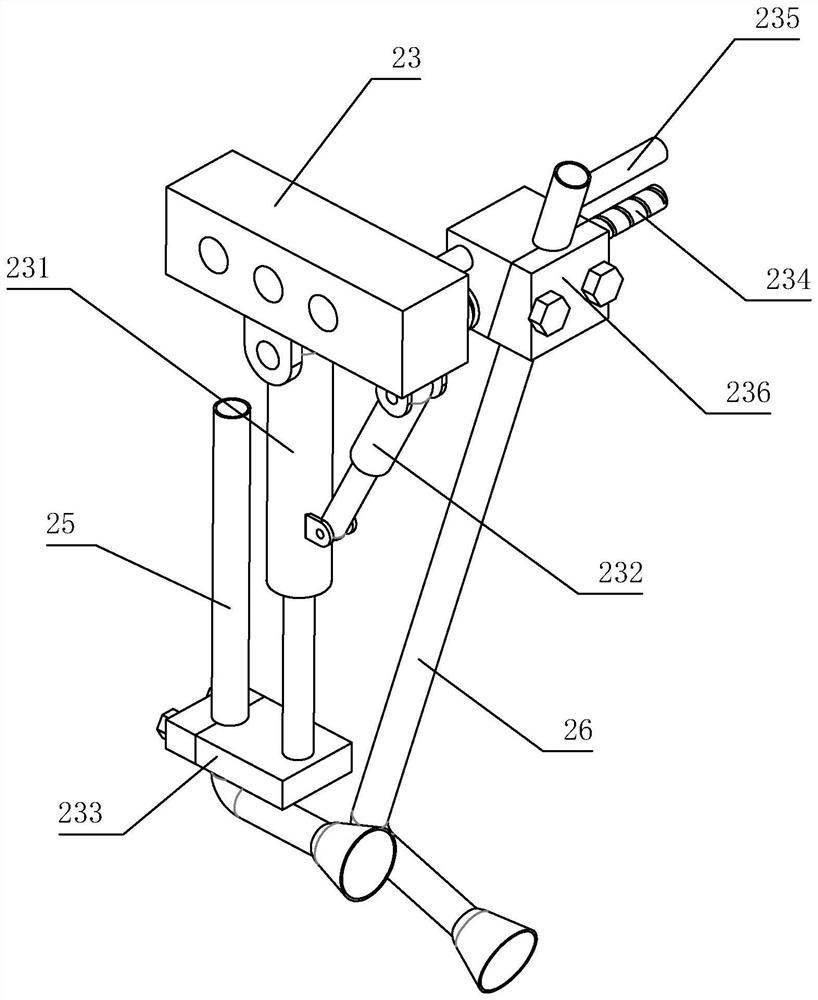

[0050] refer to figure 1 , figure 2 The sliding frame 2 is provided with an unwinding roller 21 whose axis is longitudinally arranged for installing the waterproof coiled material 4. ...

Embodiment 2

[0059] Embodiment 2: a roof waterproofing construction method, comprising the following steps:

[0060] Step S1, treatment of the base layer: including step S1.1 to clean up the loose debris on the base layer, and clean the mortar, ash and other hard blocks protruding from the base layer, rinse with water, and the moisture content of the base layer is not less than 8 after drying. %;

[0061] Step S1.2 laying a 20mm thick 1:3 cement mortar leveling layer with a gradient of 2% on the upper surface of the base layer;

[0062] Step S1.3 apply the first polyurethane waterproof layer on the dry leveling layer;

[0063] In step S1.4, after the first polyurethane waterproof layer meets the construction requirements, a second polyurethane waterproof layer is applied on the first polyurethane waterproof layer, and the application sequence of the first polyurethane waterproof layer is perpendicular to that of the first polyurethane waterproof layer;

[0064] Step S1.5 After the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com