Fully-soluble bridge plug

A bridge plug and tie rod technology, applied in the field of fully soluble bridge plugs, can solve problems such as unstable occlusion and uneven slippage, and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

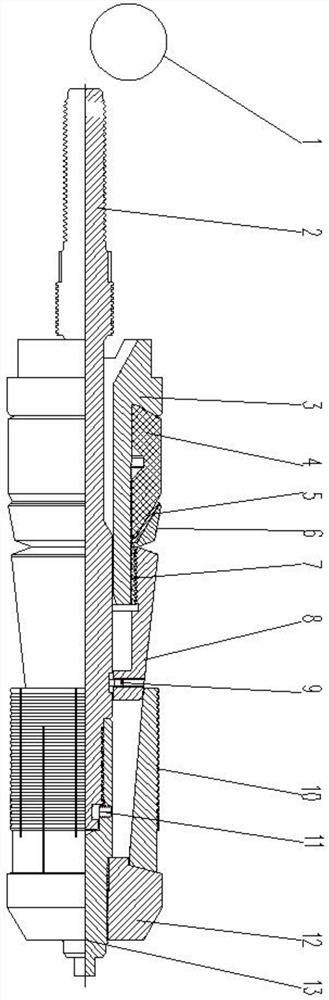

[0039] see figure 1 , 2 , 3, 4, 8, a fully soluble bridge plug includes a soluble ball 1, a central tube 3, a rubber tube 4, a back ring, a cone 8, a lock ring 7, slips 10 and guide shoes 12, and a shear rod 13 is fixedly connected to the lower end of the pull rod 2 by at least one fastening screw 11, the pull rod 12 and the shear rod 13 are made of alloy steel, and the central tube 3, the rubber tube 4, the back ring and the slip 10 are all installed and restricted On the tie rod 2 and the shear rod 13, the upper end of the tie rod 2 is connected with the setting tool through threads; the bridge plug setting is to seal the casing in the well. 13 will be taken out of the wellhead with the setting tool, and will not leave insoluble alloys in the well.

[0040] Two observation grooves 14 are milled on the upper end of the central tube 3, which can be used to observe whether the guide joint in the adapter is installed in place. The inner hole at the upper end of the central tub...

Embodiment 2

[0048] Such as Figure 5 , 6 , 7, the difference from Embodiment 1 is that the difference between the first structure and the second structure is as follows:

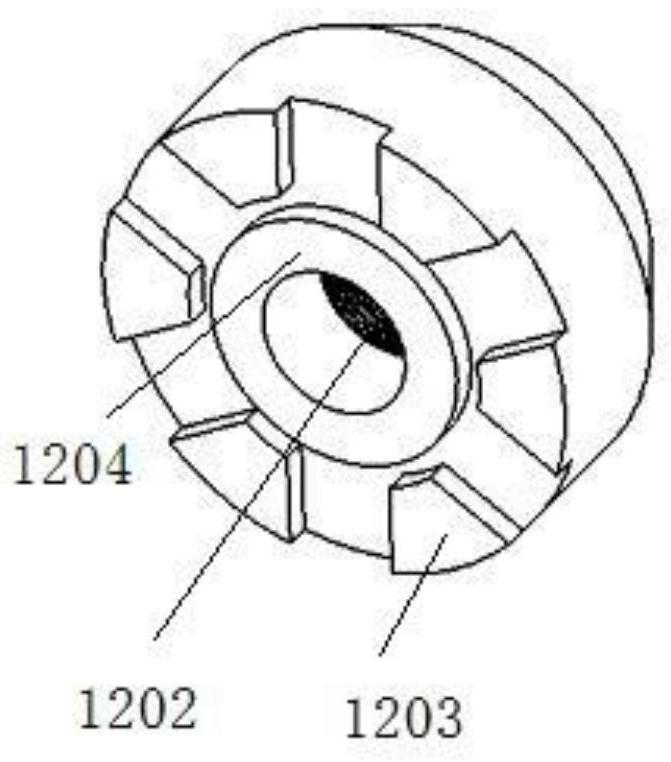

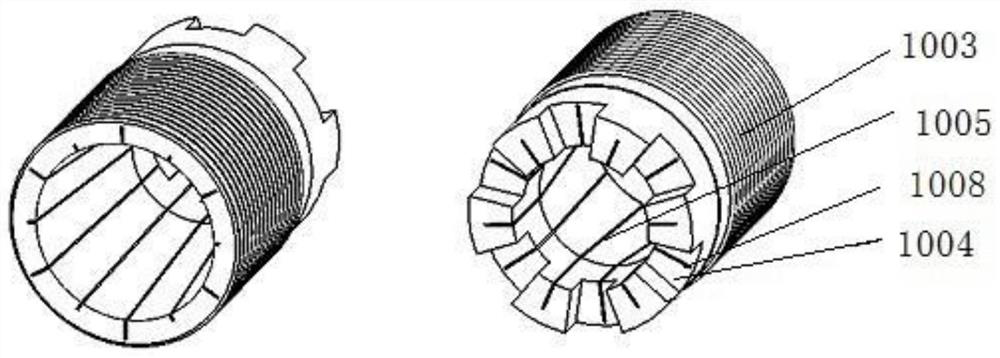

[0049] The first structure is an upper cone surface and a lower cone surface 1201 that match up and down. The upper cone surface is arranged at the lower end of the slip 10, and a circular step 1204 is provided at the upper end of the guide shoe 12; the lower cone surface 1201 is arranged at the bottom of the guide shoe 12 The upper end is located around the circular step; the upper conical surface is a 15° conical surface, which is convenient for the slips 10 to be deformed by the shoe 12 during setting and evenly opened; the upper conical surface of the slips 10 is axially circumferential The number of six third slots 1007 is distributed, and the upper end surface of the slip 10 is distributed with a number of six fourth slots 1001 on the axial circumference, and the fourth slots 1001 and the third slots 1007 are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com