Erosion corrosion interactive wear simulation test device

A simulation test and fixture technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, wear resistance testing, etc. It can solve the problems of low erosion efficiency, small number of test pieces, and inability to simulate both erosion and corrosion environments. , to achieve high efficiency, stable and reliable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

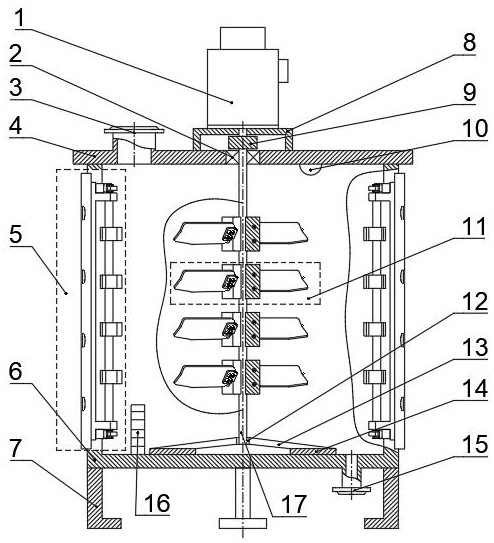

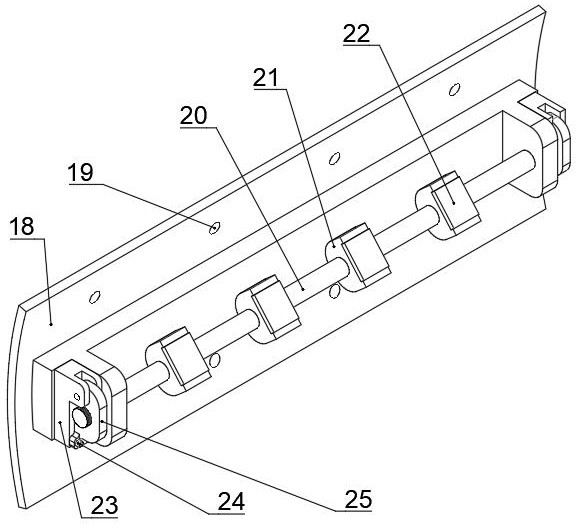

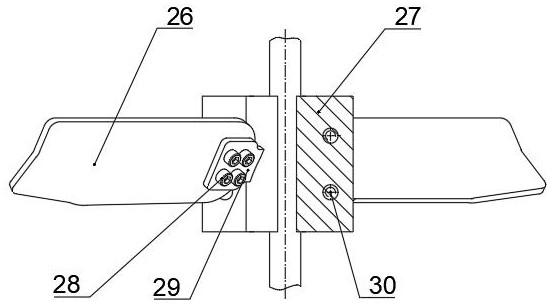

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , an erosion-corrosion interactive wear simulation test device of the present invention, comprising a working motor 1, a ball bearing 2, a feed flange 3, an upper sealing cover 4, a clamp unit 5, a test barrel body 6, a bottom support leg 7, and a motor installation Frame 8, coupling 9, thermometer 10, fluid power unit 11, rotating support ring 12, four-legged support 13, four-legged support base 14, discharge flange 15, bottom heating device 16, rotating shaft 17, Doppler Ultrasonic flowmeter31. The working motor 1 has a continuously variable speed, is fixedly connected with the rotating shaft 17 through the coupling 9, provides power for rotation and can adjust different speeds.

[0030] The upper sealing cover 4 is in the shape of a disk, and the motor is installed in the middle to install 8 frames, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com