Offshore platform vertical pipe detection device

A detection device and offshore platform technology, which is applied to measurement devices, uses sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve problems such as unsatisfactory results, scattered emergency maintenance, hidden dangers in the safe operation of submarine pipelines, etc., to meet the safety of personnel And easy to operate, reliable and accurate test results, to achieve the effect of reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

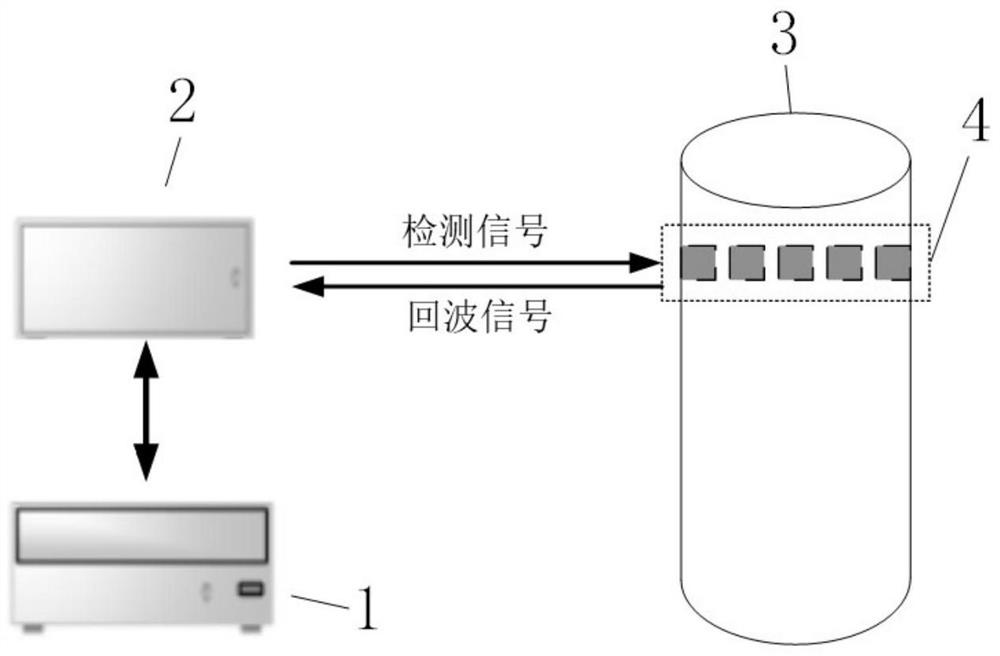

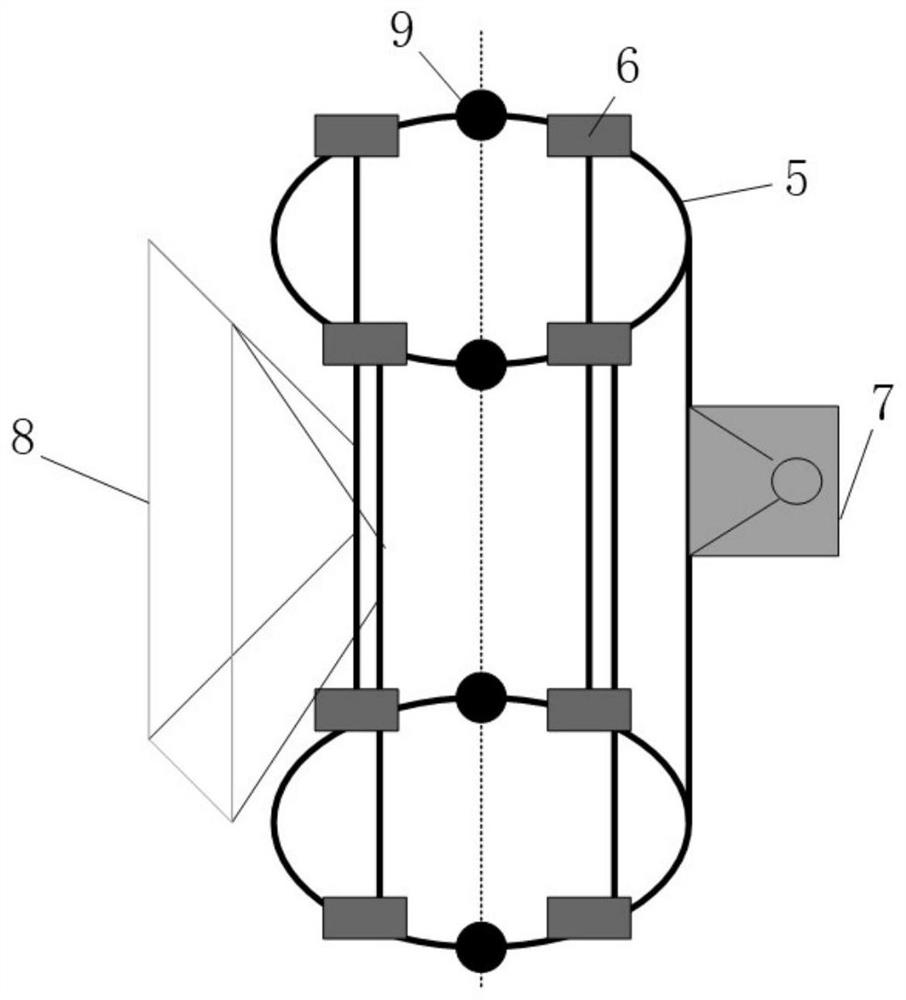

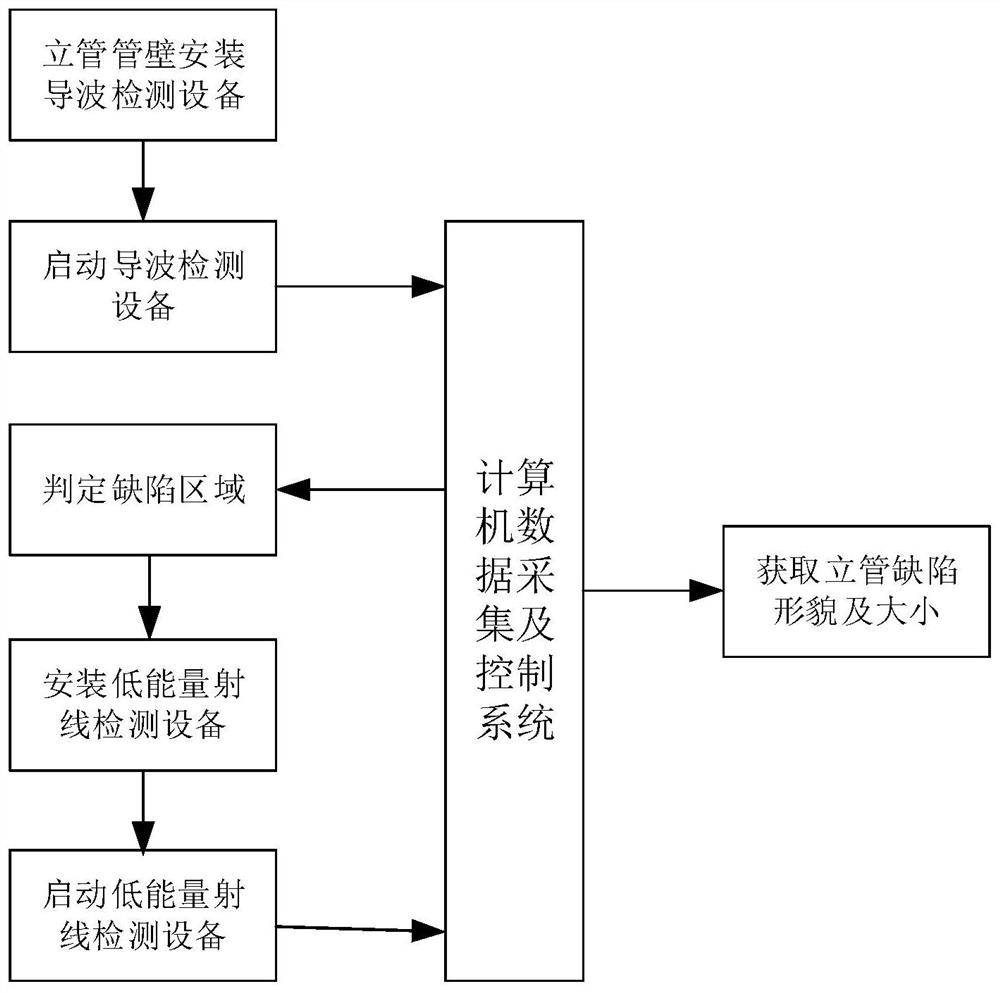

[0026] The offshore platform standpipe detection device of the present invention includes ultrasonic guided wave detection equipment, low-energy ray detection equipment and riser detection fixed equipment, and integrates the two detection technologies of ultrasonic guided wave and low-energy ray to realize offshore platform riser Accurate and fast detection, discover the location and shape of riser defects, and use it for corrosion detection and corrosion status evaluation of riser pipes on offshore platforms. The ultrasonic guided wave detection equipment is used to quickly locate the defect area of the riser, the low-energy ray detection equipment is used to accurately detect the defect area of the riser, and the riser detection and fixing device is used to fix the low-energy ray detection equipment on the On the riser of the offshore platform, it can move radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com