A method of checking whether the welding lock bottom is completely removed

A technology of complete removal and bottom locking, applied in geophysical surveying, instruments, etc., can solve problems such as no observation or detection, flash falling off, narrow space, etc., and achieve the effect of improving the level of detection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

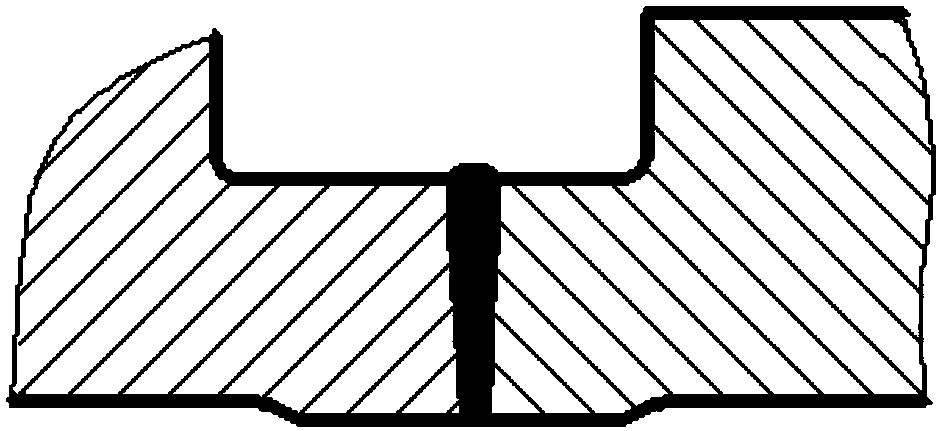

[0024] (1) For the single piece to be welded such as Figure 10 As shown, change the structure of the bottom lock, and increase the lap length of the joint with the bottom lock by 2-3mm compared with the joint without the bottom lock, as shown Image 6 shown.

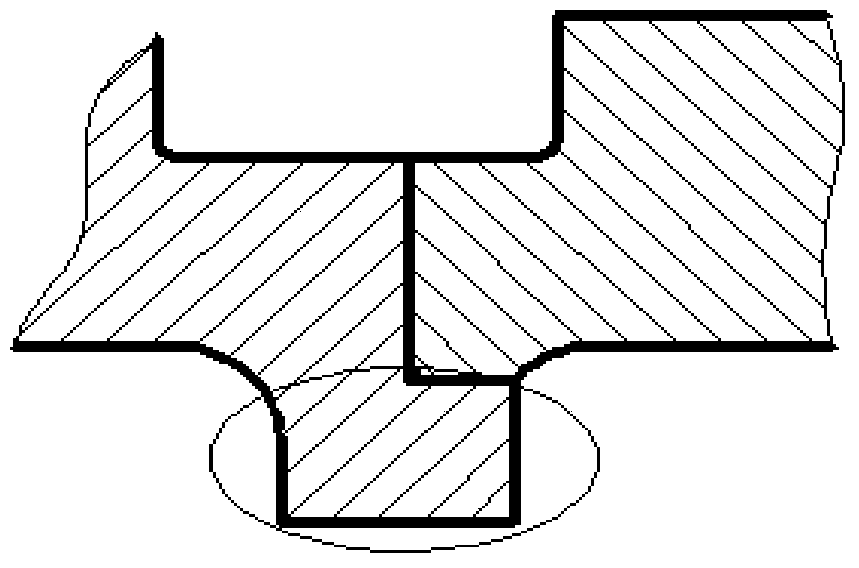

[0025] (2) Perform normal welding; if Figure 7 shown; turning.

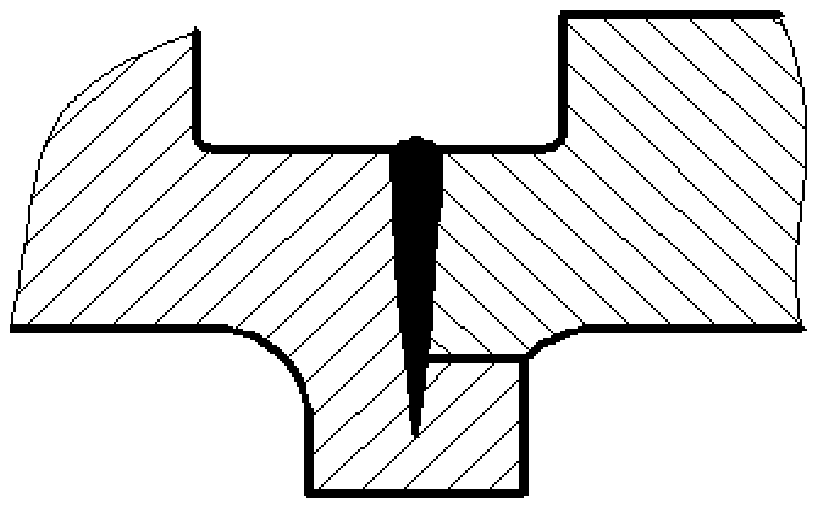

[0026] (3) Inspect the residual flashing of the bottom lock after the bottom lock process is completed. Use your fingers to touch the bottom side of the lock to see if there are any reserved platforms; With this small platform, it is assumed that after the completion of the car bottom lock process, there is a residual flash on the bottom lock, that is, the bottom lock has not been completely removed, but there are several to a dozen thin rings left on the bottom of the lock, such as Figure 8 shown. You can use your fingers to touch the extra 2-3mm platform lock bottom reserved on the bottom side of the lock to detect whether the bottom lock has been ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com