Wire solder weld mark detection apparatus

A technology for detecting equipment and weld marks, which is applied in the field of welding wire and weld mark detection equipment, and can solve problems such as excessive use of corrosive potions, safety risks, and difficulty in complete recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

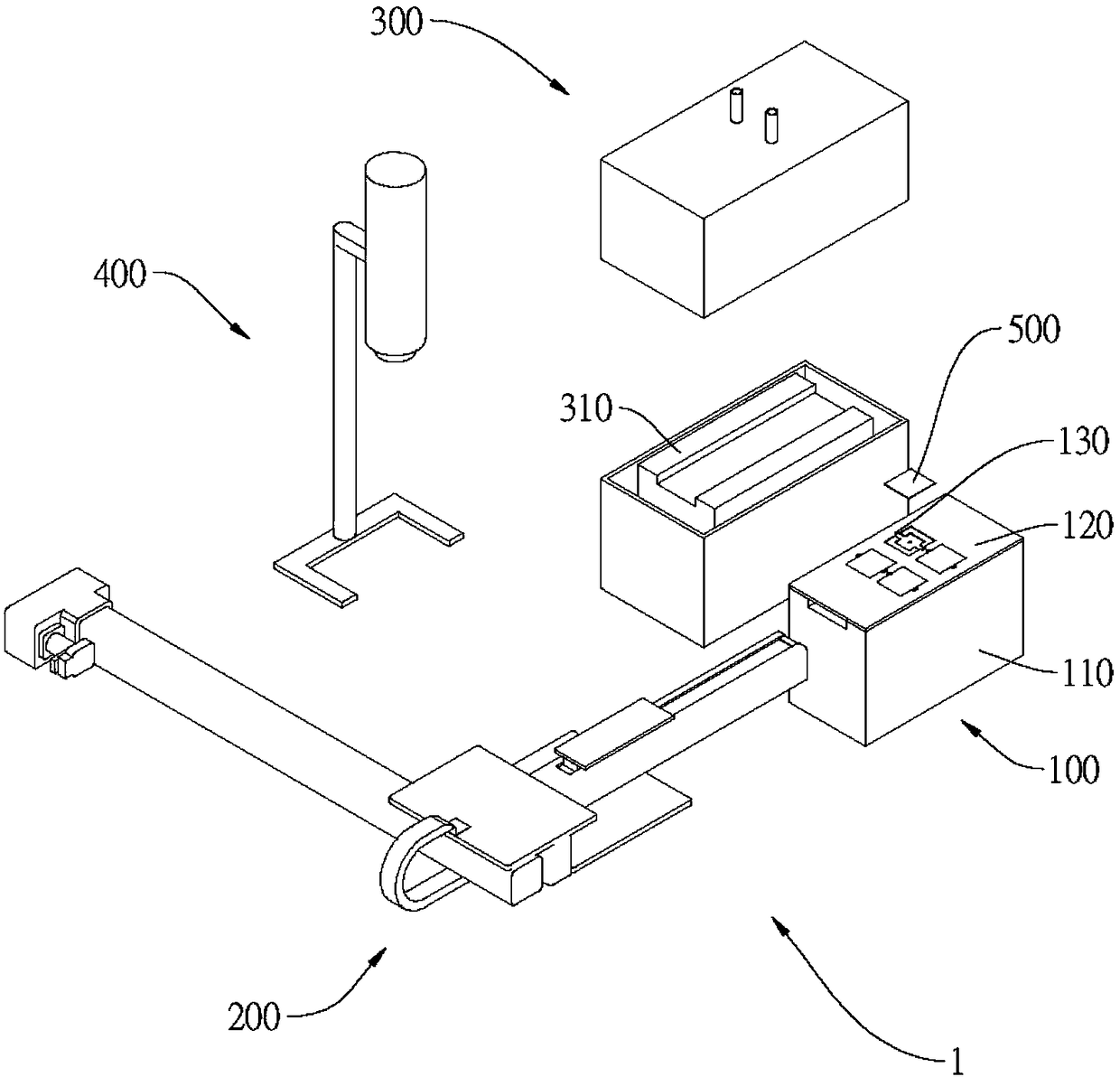

[0026] First, see figure 1 Shown is a perspective view of the welding wire scar detection equipment 1 of the present invention, it can be seen from the figure that the welding wire weld trace detection equipment 1 of the present invention includes an adjacent placement platform 100, a moving device 200, and a working chamber 300 , the image processor 400, by the above-mentioned device to change the high-risk corrosion operation into a fully automated operation without safety hazards, the following are the above-mentioned placement platform 100, mobile device 200, working chamber 300, and image processor 400 main structure.

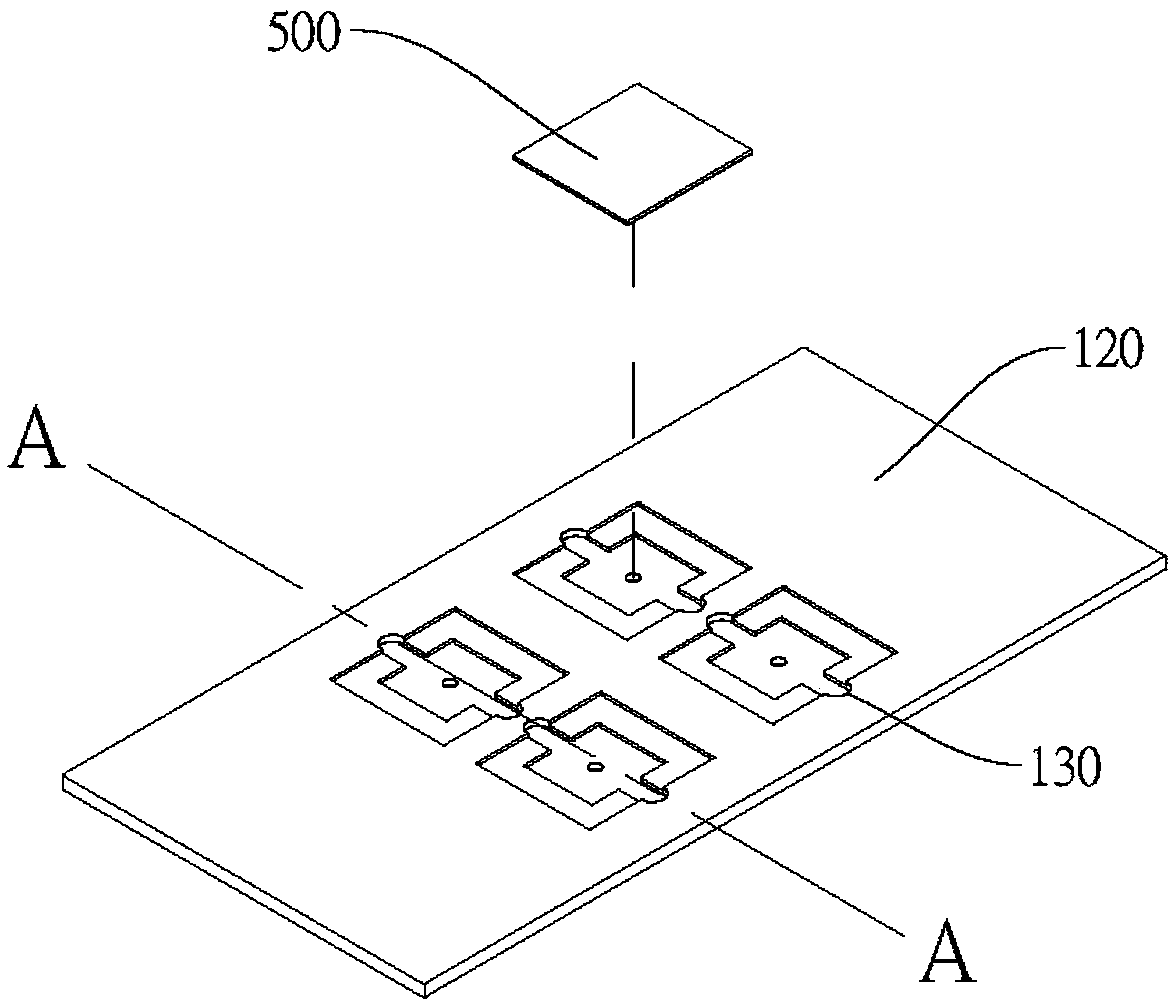

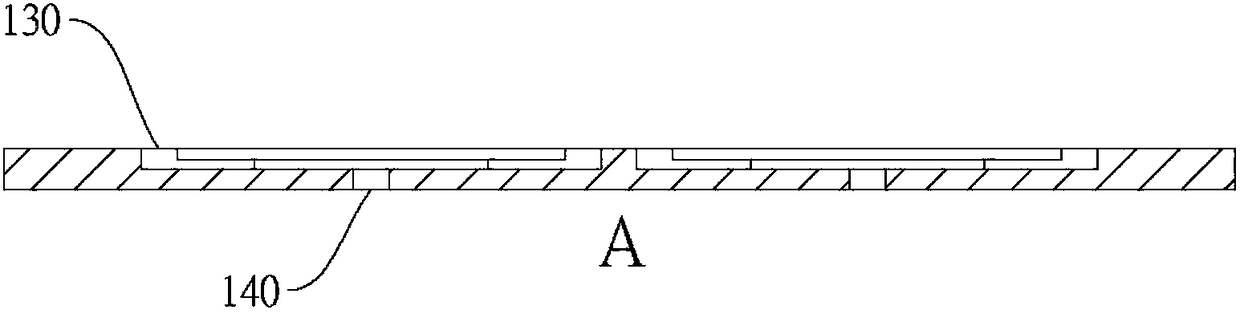

[0027] The placement platform 100 is provided with a placement seat 110 and an additional circuit board 120, and the additional circuit board 120 is provided with several grooves 130, and the grooves 130 can be provided with springs, dampers or other equivalent components, so that the grooves 130 can be completed. It accommodates an IC board 500 to avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com