Detection method of detecting Young modulus of anisotropic material surface layer based on surface acoustic wave

A surface acoustic wave and anisotropy technology, applied in measurement devices, material analysis, material analysis by optical means, etc., can solve problems such as affecting test results, physical and chemical properties are easily affected by temperature, etc., to simplify measurement steps , Improve the test efficiency, improve the effect of the detection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

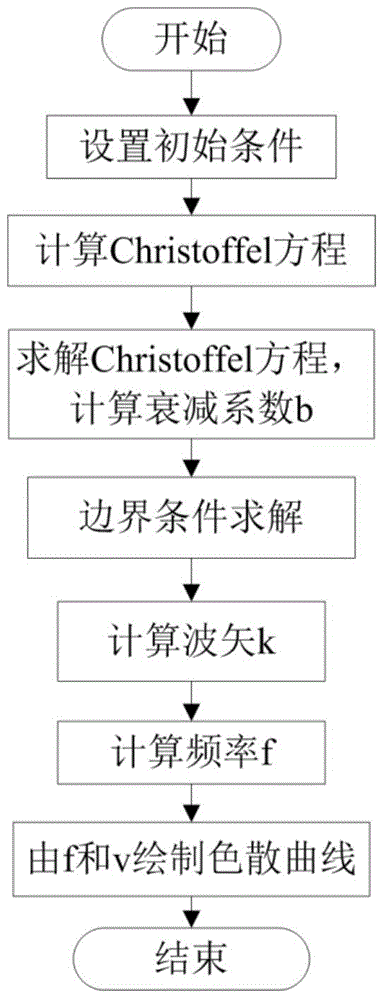

[0036] 101: The short-pulse laser beam generated by the pulse laser excites the surface acoustic wave signal on the surface of the anisotropic material specimen, performs Fourier transform and data fitting processing on the surface acoustic wave signal, and obtains the dispersion curve v of the specimen in a certain direction (f);

[0037] v ( f ) = 2 π ( x 2 - x 1 ) f Φ 2 ( f ) - Φ 1 ( f )

[0...

Embodiment 2

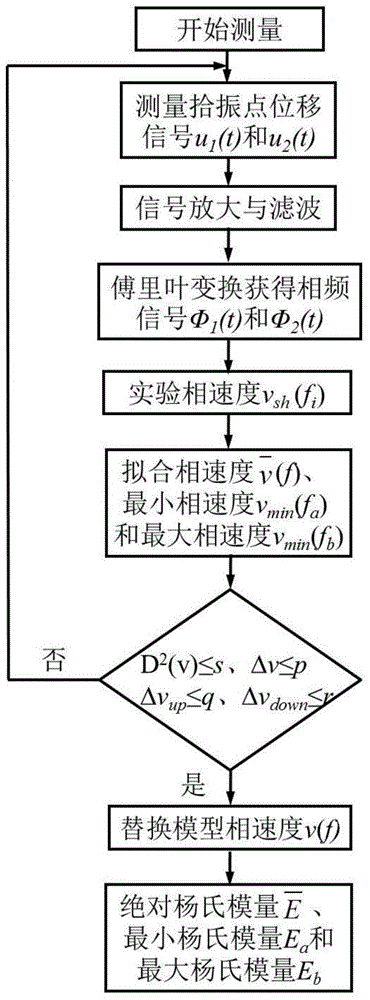

[0057] 201: Obtain the surface acoustic wave dispersion curve and perform curve fitting to obtain the dispersion curve v(f) of the specimen in a certain direction;

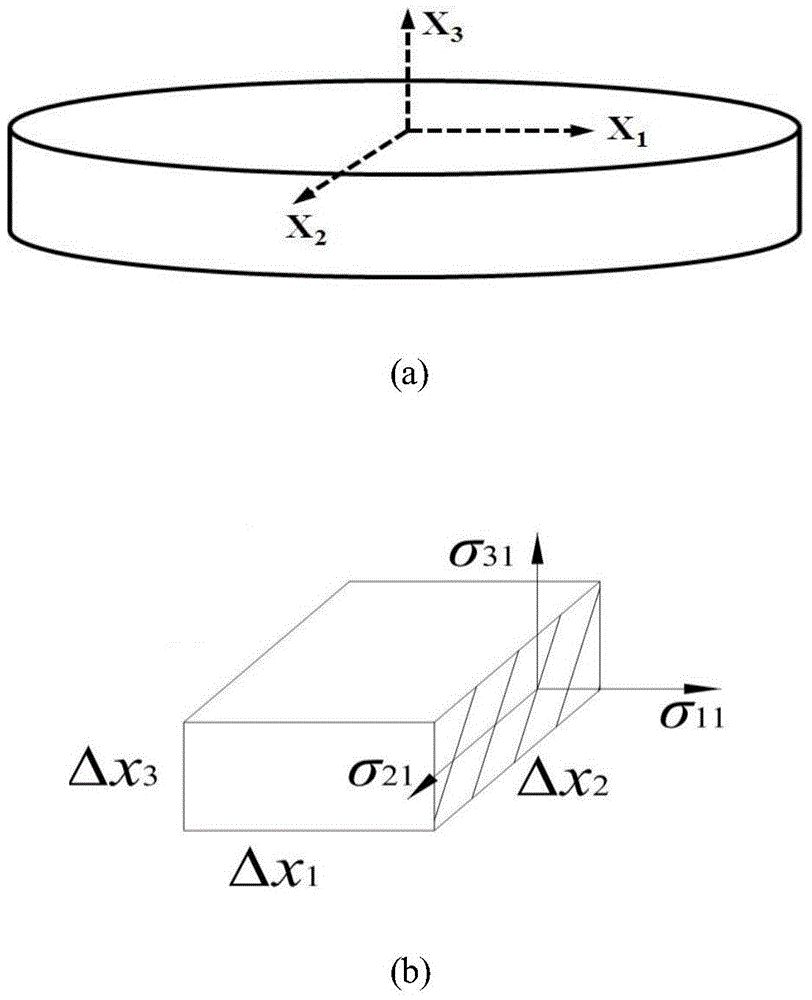

[0058] The focused beam of short-pulse laser is used to generate thermoelastic effect on the surface of the test piece, and high-frequency composite ultrasonic surface waves are obtained. Two distances x from the excitation point in a straight line direction 1 and x 2 At the place, the piezoelectric sensor is used together with the data acquisition circuit to pick up, convert, amplify and filter the particle vibration on the surface of the specimen to obtain an effective analog electrical signal (u 1 (t) and u 2 (t)) and sent to a digital oscilloscope for subsequent processing. Use a digital oscilloscope and a computer to perform Fourier transform on the obtained signal, realize the time-frequency domain conversion signal of the vibration pickup signal, and obtain the phase frequency vibration pickup signal Φ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com