Temperature control method of constant-temperature metal bath

A temperature control method and constant temperature metal technology, applied in the direction of temperature control using electric methods, can solve the problems of affecting the working accuracy and uneven heating of the constant temperature metal bath, so as to improve reliability, avoid long-term temperature control failure, and facilitate The effect of real-time processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

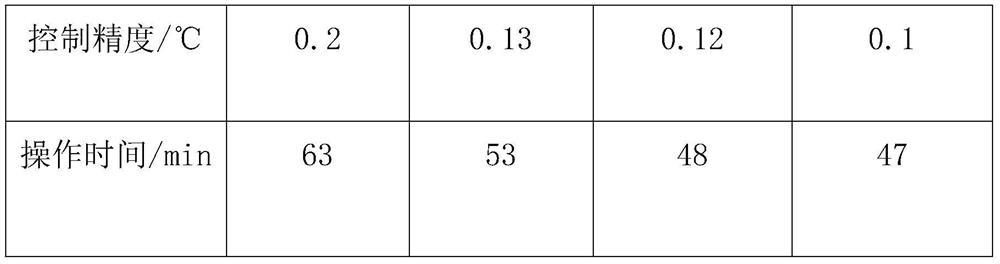

Embodiment 1

[0032] Step 1: The overall preparation of the equipment: Clean the entire device with a soft cotton towel, and test each independent function of the completely cleaned equipment to ensure that the function is normal;

[0033] Step 2: Turn on the power and preheat the module: connect the device to a stable power supply, fully turn on the device, preheat the device for 15 minutes, and then set the predetermined temperature;

[0034] Step 3: Put the sample into the device, and control the basic temperature: After 5 minutes, when the temperature is uniform, put the test tube into the device, use a cotton swab dipped in distilled water to clean the cone hole of the module, monitor the temperature of the sample, and remove it in time. The data is fed back to the control module without delay, and the temperature is displayed instantly on the LCD screen;

[0035] Step 4: Multi-module monitoring and comparison display: multiple temperature monitoring modules in different positions moni...

Embodiment 2

[0040] Step 1: The overall preparation of the equipment: Clean the entire device with a soft cotton towel, and test each independent function of the completely cleaned equipment to ensure that the function is normal;

[0041] Step 2: Turn on the power and preheat the module: connect the device to a stable power supply, fully turn on the device, preheat the device for 20 minutes, and then set the predetermined temperature;

[0042] Step 3: Put the sample into the equipment, and control the basic temperature: After 8 minutes, when the temperature is uniform, put the test tube into the equipment, and use a cotton swab dipped in distilled water to clean the cone hole of the module, monitor the temperature of the sample, and remove it in time. The data is fed back to the control module without delay, and the temperature is displayed instantly on the LCD screen;

[0043] Step 4: Multi-module monitoring and comparison display: multiple temperature monitoring modules in different posi...

Embodiment 3

[0048] Step 1: The overall preparation of the equipment: Clean the entire device with a soft cotton towel, and test each independent function of the completely cleaned equipment to ensure that the function is normal;

[0049] Step 2: Turn on the power and preheat the module: connect the device to a stable power supply, fully turn on the device, preheat the device for 25 minutes, and then set the predetermined temperature;

[0050] Step 3: Put the sample into the equipment, and control the basic temperature: After 10 minutes, when the temperature is uniform, put the test tube into the equipment, use a cotton swab dipped in distilled water to clean the cone hole of the module, monitor the temperature of the sample, and remove it in time. The data is fed back to the control module without delay, and the temperature is displayed instantly on the LCD screen;

[0051] Step 4: Multi-module monitoring and comparison display: multiple temperature monitoring modules in different positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com