Thyristor element, thyristor element assembly structure and soft starter

A technology for assembling structure and thyristor, which is applied in the direction of thyristor, starter parts, electrical components, etc., can solve the problems that are not conducive to improving the service life of the thyristor element 5, the popularization and application of the thyristor element 5, and the difficulty of the assembly process, and achieve assembly The effect of low process difficulty, avoidance of structural instability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing.

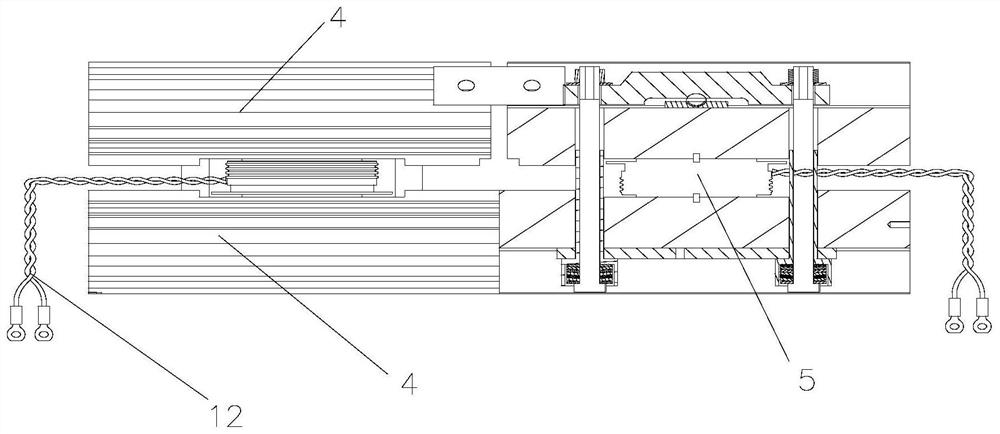

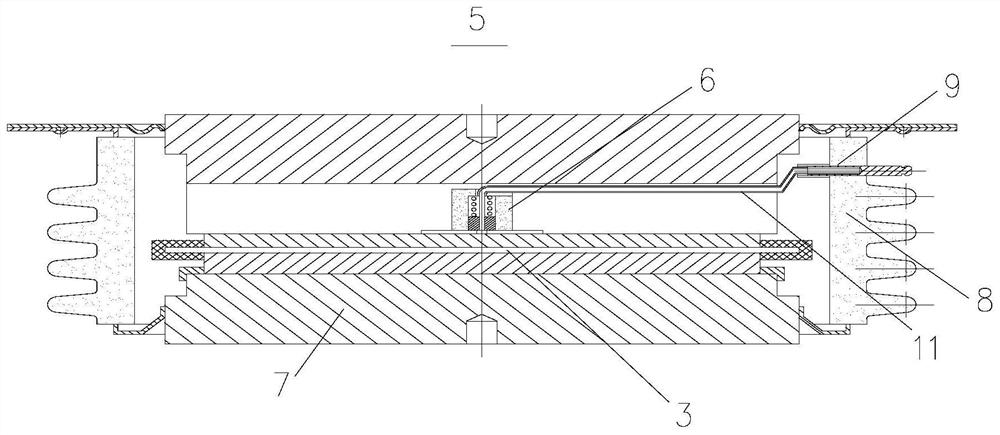

[0053] Such as Figure 4 to Figure 8 As shown, this embodiment provides a thyristor element, the thyristor element includes a gate assembly 80 and a chip package assembly 60, and the chip package assembly 60 is provided with a blind hole 608 at least partially fixedly connected to the gate assembly 80, and the blind hole 608 The axis is perpendicular to the chip 604 in the chip package assembly 60, and the gate assembly 80 includes: a gate pin 803, which extends from the inside of the gate assembly 80 and whose bottom abuts against the chip gate of the chip 604; a tab 801, which The top of the gate assembly 80 protrudes for connecting the gate pin 803 and the lead wire 20 .

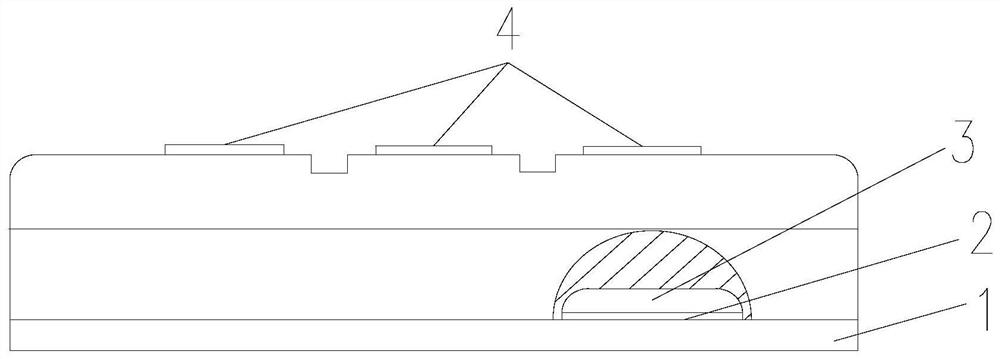

[0054] Such as figure 2 with image 3 As shown, in the prior art, such as image 3 As shown, the gate assembly 6 of the thyristor element 5 is packaged inside its chip package assembly 7, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com