Clearance adjustable deashing device for building construction

A technology of building construction and dust cleaning device, which is applied in the direction of cleaning method using gas flow, vibration suppression adjustment, cleaning method and utensils, etc., which can solve the health injury of construction workers, improve the quality and efficiency of dust removal and dust removal, and secondary dust raising and other issues, to achieve good mobility and shock absorption performance, improve efficiency and quality, and achieve stable adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

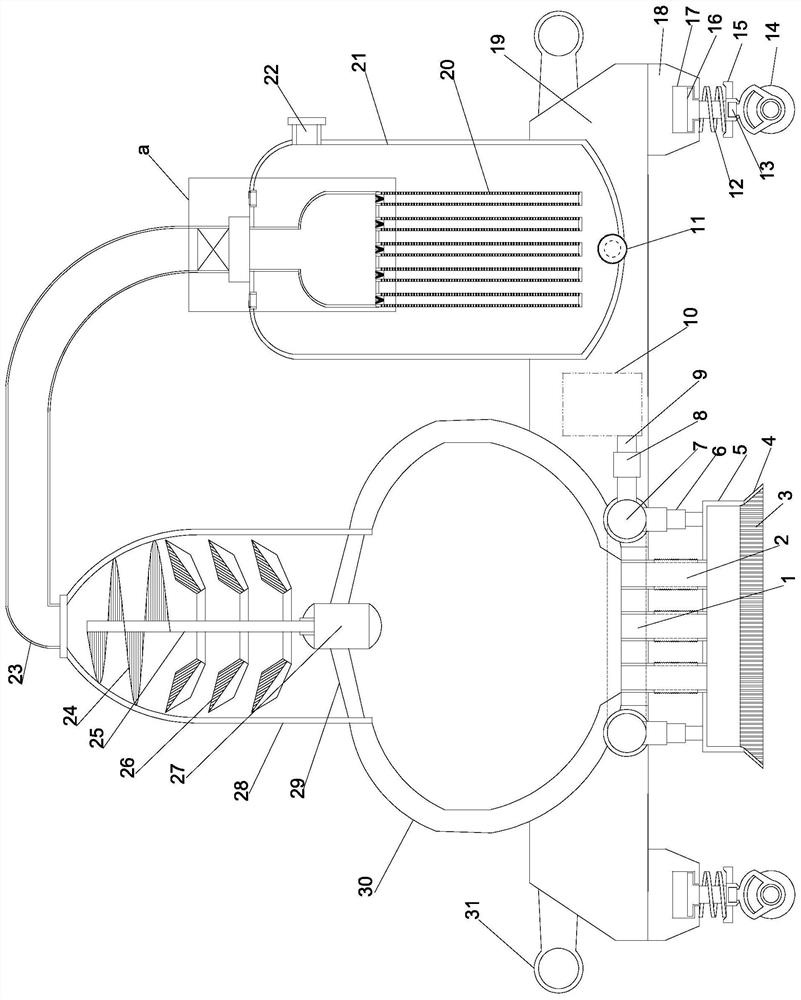

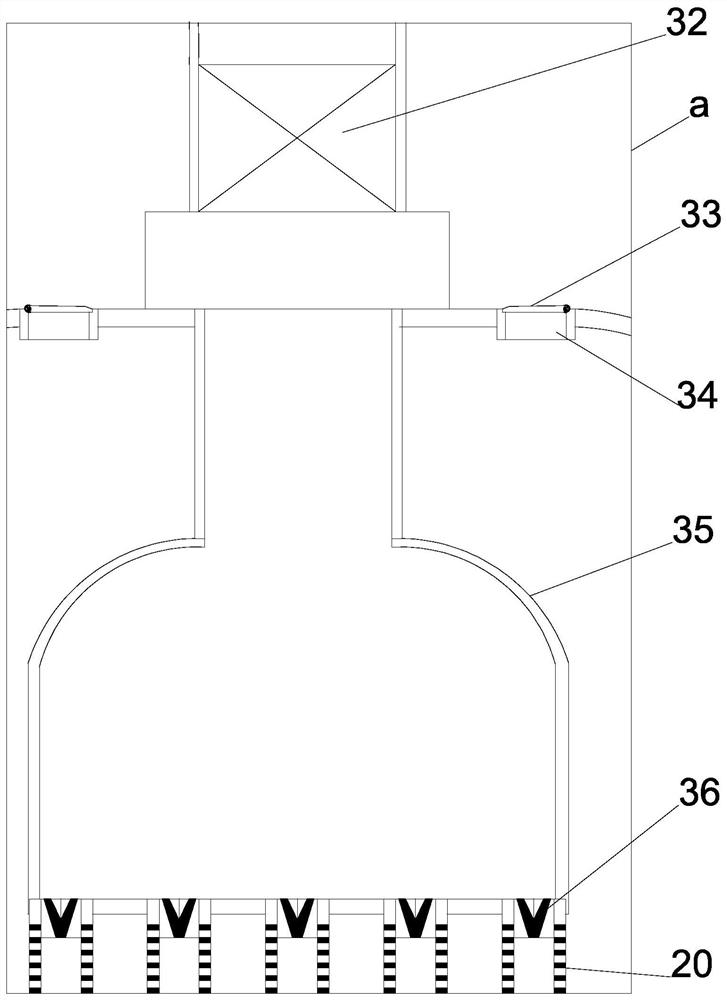

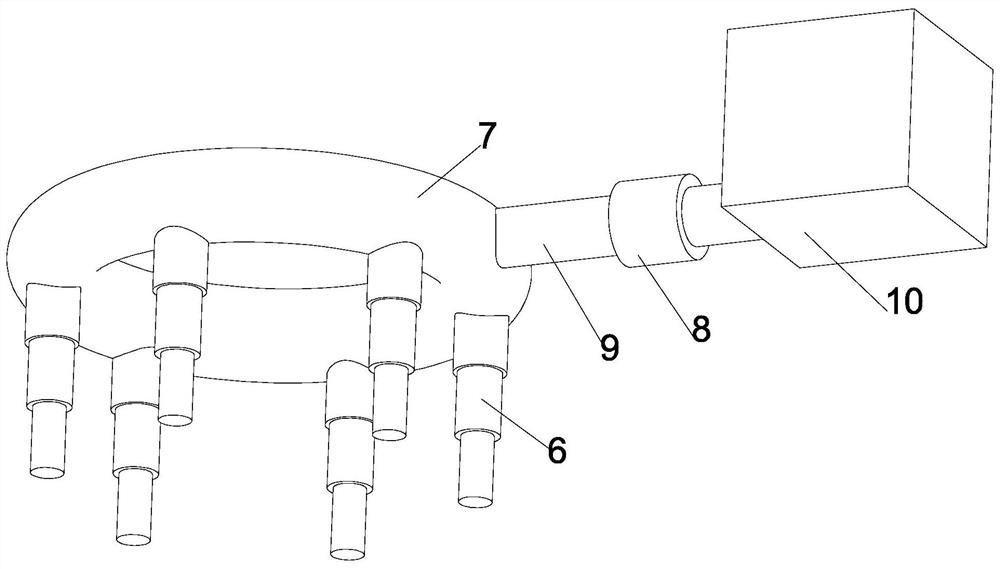

[0021] see Figure 1~3 , in the embodiment of the present invention, a kind of clearance-adjustable ash removal device for building construction, comprises the mobile mounting plate 19 that is arranged horizontally, and the two ends of mobile mounting plate 19 are all horizontally provided with traction ring 31, and the lower end of mobile mounting plate 19 The four corners are all vertically provided with support installation columns 18, and the right below the support installation columns 18 are all horizontally provided with a lifting installation plate 15, and the middle position of the lifting installation plate 15 is all vertically downwardly provided with a limit turret 13, a limit turret The lower end of 13 is all provided with moving guide wheel 14 by rotating shaft, and the middle position of the lower half section of described support mounting post 18 is all vertically provided with limit guide groove 17, coordinates limit guide groove 17 and all is provided with lim...

Embodiment 2

[0024] On the basis of Embodiment 1, through the cooperation of the steering turret and the moving guide wheel 14, the device can be turned and moved conveniently. The cooperation of the shock spring 12 makes the device have good movement stability, and the limit ensures that the porous deflector 4 and the ground always maintain a safe gap, and the exhaust hole 34 and the reset rotating plate 33 on it make it difficult for external dust to enter internal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com