Withdrawal and straightening machine of modular structure and overhauling method thereof

A tension leveler and modular technology, which is applied in the field of tension leveler with modular structure and its maintenance, can solve the problems of inability to quickly maintain, time-consuming and low efficiency of the tension leveler, and achieve fast and efficient maintenance, maintenance and spare parts. The effect of cost reduction and high spare parts turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

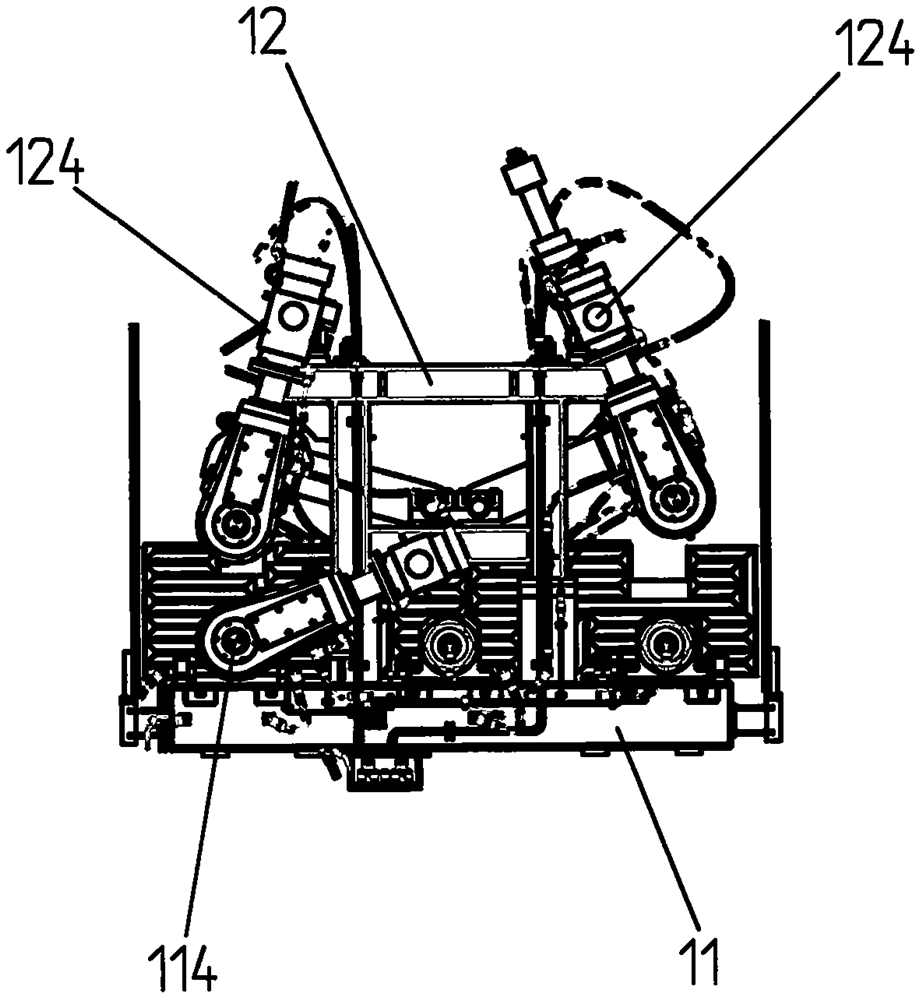

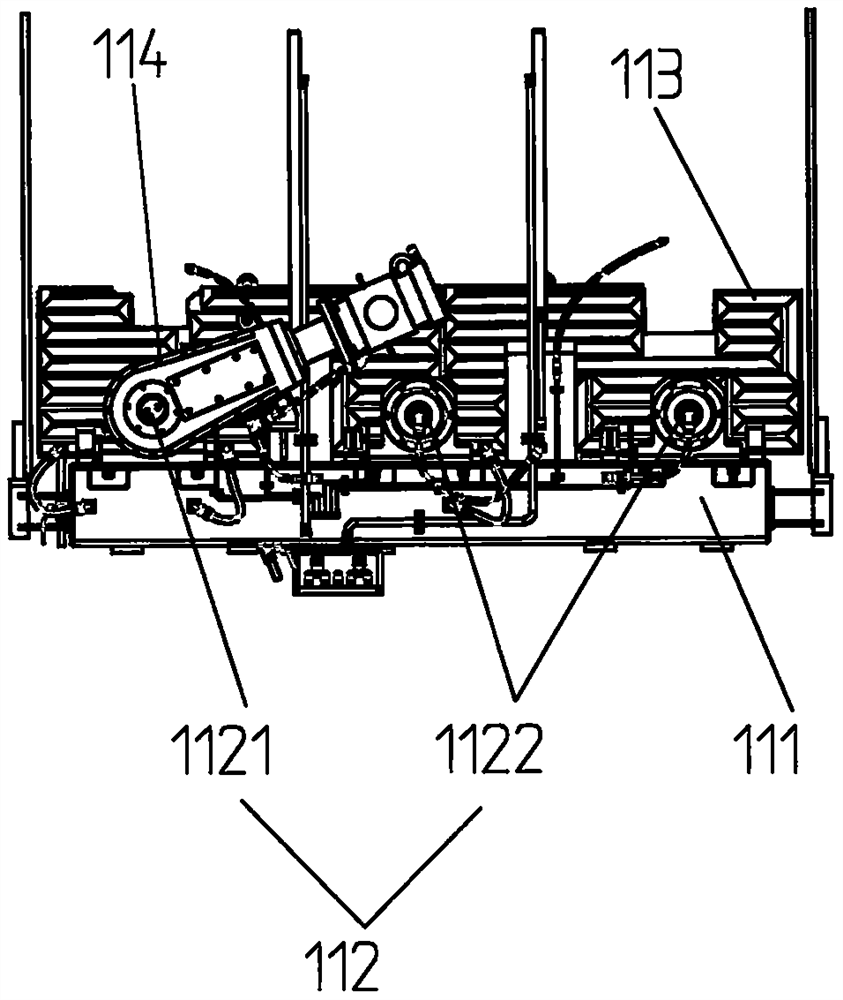

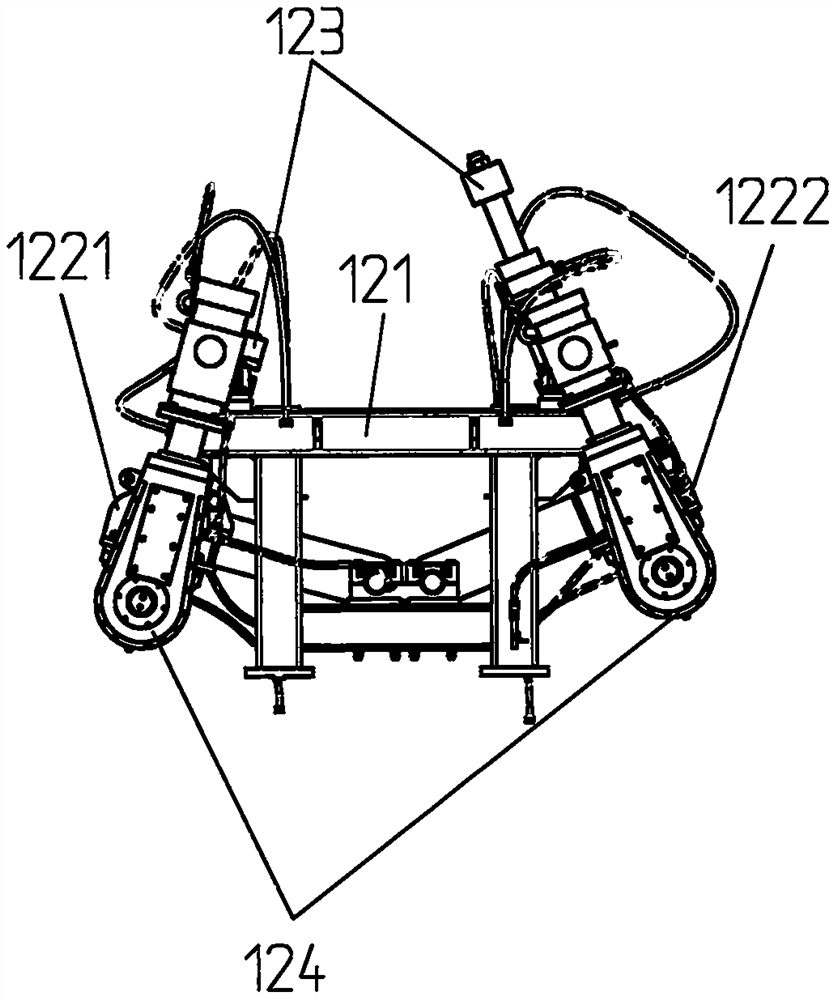

[0030] Embodiment 1, a kind of tension straightening machine of modular structure of the present embodiment, refer to Figures 1 to 5 As shown, it includes: a lower base module 11 and an upper frame module 12 .

[0031] The lower base module 11 takes the base module 111 as the core, and the lower roller table assembly module 112 is installed on the base module 111; the lower transmission device module 114 is installed on the base module 111 through lugs and pins, and assembled with the lower roller table through bushings The roller shafts of the module 112 cooperate to drive the roller shafts of the lower roller table assembly module 112 to rotate; the water-cooled protective cover module 113 is also installed on the base module 111 to cover the lower roller table assembly module 112 as a whole and play a role of cooling protection. The upper frame module 12 takes the frame module 121 as the core, and the upper roller table assembly module 122 is installed on the frame module ...

Embodiment 2

[0032] Embodiment 2, a kind of tension straightening machine of modular structure of this embodiment, refer to Figures 6 to 9 shown.

[0033] In the specific implementation, when a part of the tension leveler breaks down, use the continuous casting machine to change the pouring time, open the quick locking device of the tension leveler, turn off energy media such as water, oil, electricity, etc., and disassemble the pipe joints. Lift out the tension leveler as a whole from the vertical direction, hoist the new tension leveler, use the alignment device for quick alignment, after the piles are in place, install the pipe joints, open the energy medium, and control the quick locking device of the tension leveler to lock.

[0034] Lift the tension leveler after offline to the maintenance area, remove the nuts 23 of the T-bolts connecting the base and the frame, disassemble the hydraulic hard pipe clamp 24, and decompose the tension leveler as a whole into the lower base module 21...

Embodiment 3

[0039] Embodiment 3, the overhaul method of the modular structure tension leveler of the present embodiment is implemented by the tension leveler of the modular structure of the above-mentioned embodiment 2, see Figure 10 shown, including the following steps:

[0040] S31. Steps for the overall replacement of the tension leveler

[0041] When a part of the tension leveler breaks down, use the continuous casting machine to change the pouring time, open the quick locking device of the tension leveler, turn off energy media such as water, oil, electricity, etc., disassemble the piping joints, and pull the tension leveler from the Lift out the whole in the vertical direction, lift the new tension leveler, and use the alignment device to quickly align it. After the pile is in place, install the pipe joints, open the energy medium, and control the quick locking device of the tension leveler to lock.

[0042] S32, the step of removing the module to which the faulty component belong...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap