Mobile phone camera module rotating, detecting and assembling device

A camera module, mobile phone camera technology, applied in the direction of measuring devices, machine/structural component testing, optical instrument testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

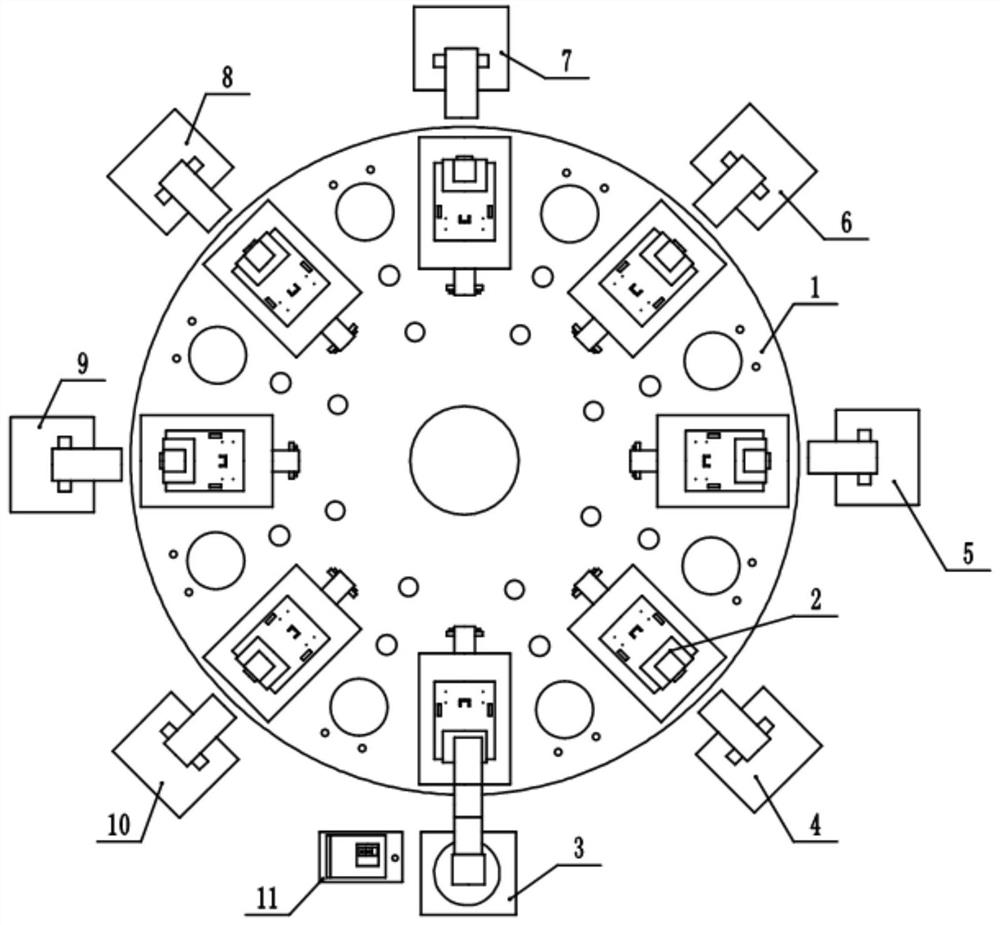

[0036] Such as figure 1 As shown, the mobile phone camera module rotation detection and assembly device of the present embodiment includes a turntable 1, a manipulator 3, several assembly modules and a detection module, and the turntable 1 is provided with several fixed positions 2 for placing the camera module in the upper direction, and the manipulator 3 It is used to place the camera module on the fixed position 2 or remove the camera module from the fixed position 2; the manipulator 3, the assembly module and the detection module are distributed along the circumference of the turntable 1. The detection module is used to detect the camera module on the fixed position 2 and generate detection information; the detection information includes normal or fault.

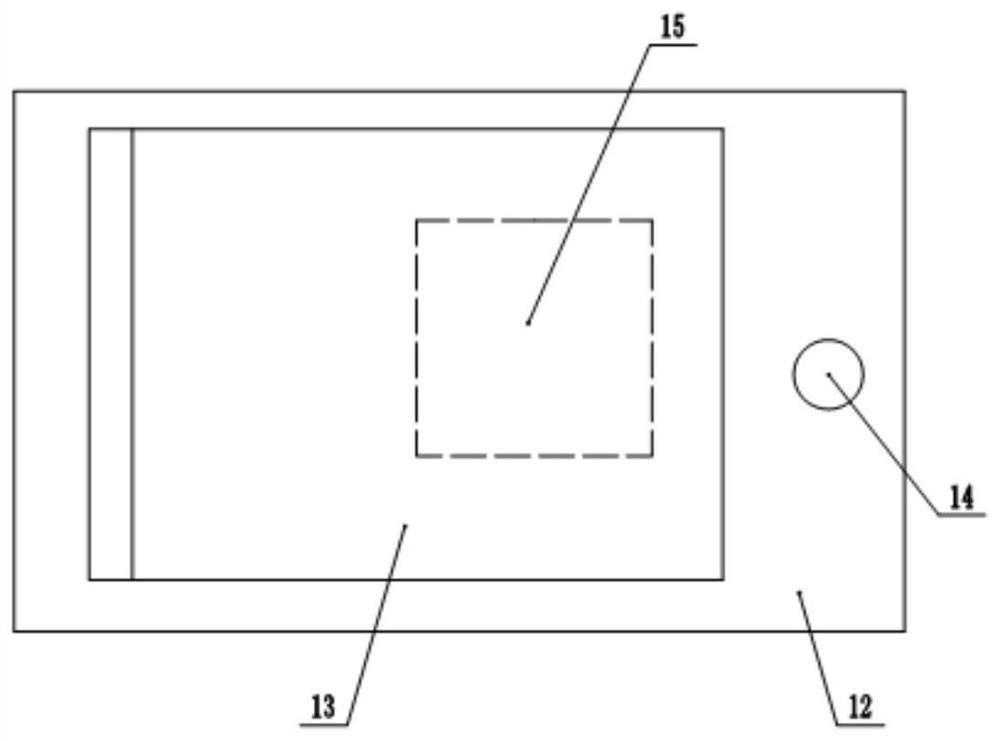

[0037] The assembly module includes a dispensing unit 7, a UV curing unit 8, and a burning station unit; the detection module includes a black spot detection unit 4, an automatic focusing unit 5, a white spot detection u...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that in this embodiment, the processing module is also used to obtain the production information of the camera module; the top surface of the housing is also provided with a storage slot for placing a typical faulty camera module; Modules are placed in storage slots. In this implementation, the production information refers to the initial stage of mass production or the stable period of mass production, and the typical faulty camera module refers to a camera module with preset typical faults after manual confirmation.

[0049] The processing module is also used to record the usage times of the standard camera module, and when the usage times of the standard camera module is greater than the preset replacement times, the processing module is also used to generate replacement information. The number of times of replacement is 50-100 times, which is 50 times in the present embodiment. Regularly replace the standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com