Stamping die for part production

A technology for stamping dies and parts, used in presses, forming tools, manufacturing tools, etc., can solve the problems of lack of multi-angle azimuth stamping ability, difficult to achieve integrated preheating, etc., to achieve reliable connection, convenient inspection and maintenance, and realization of low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

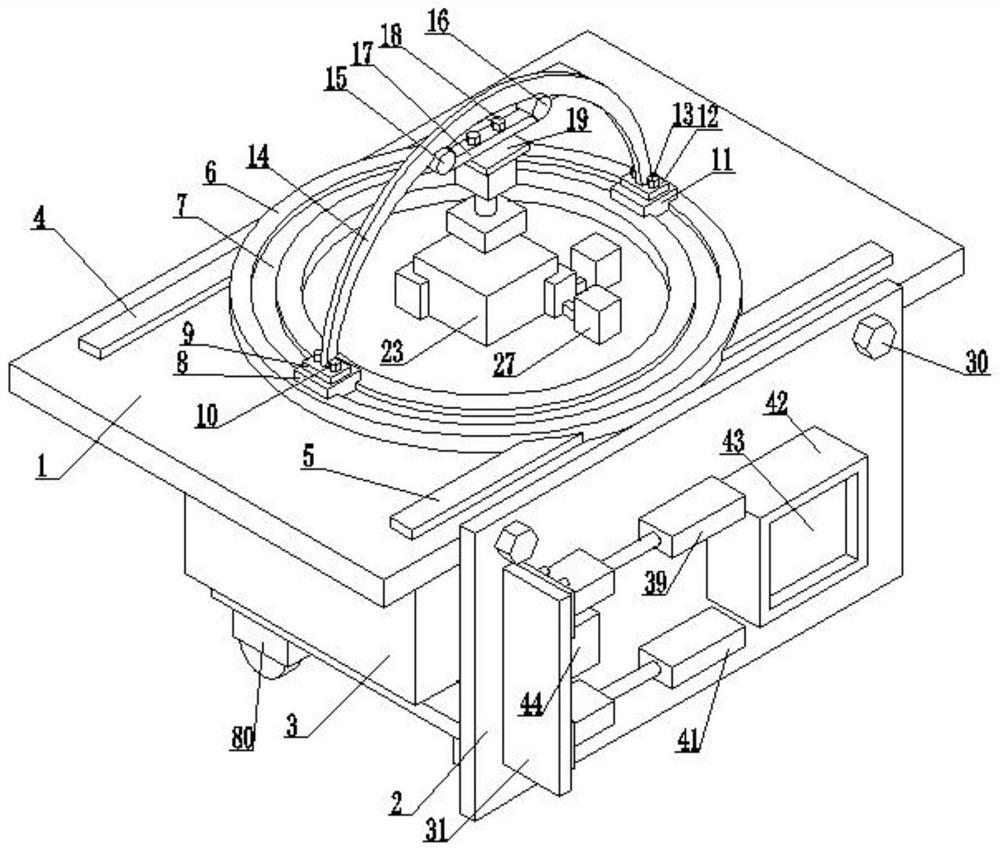

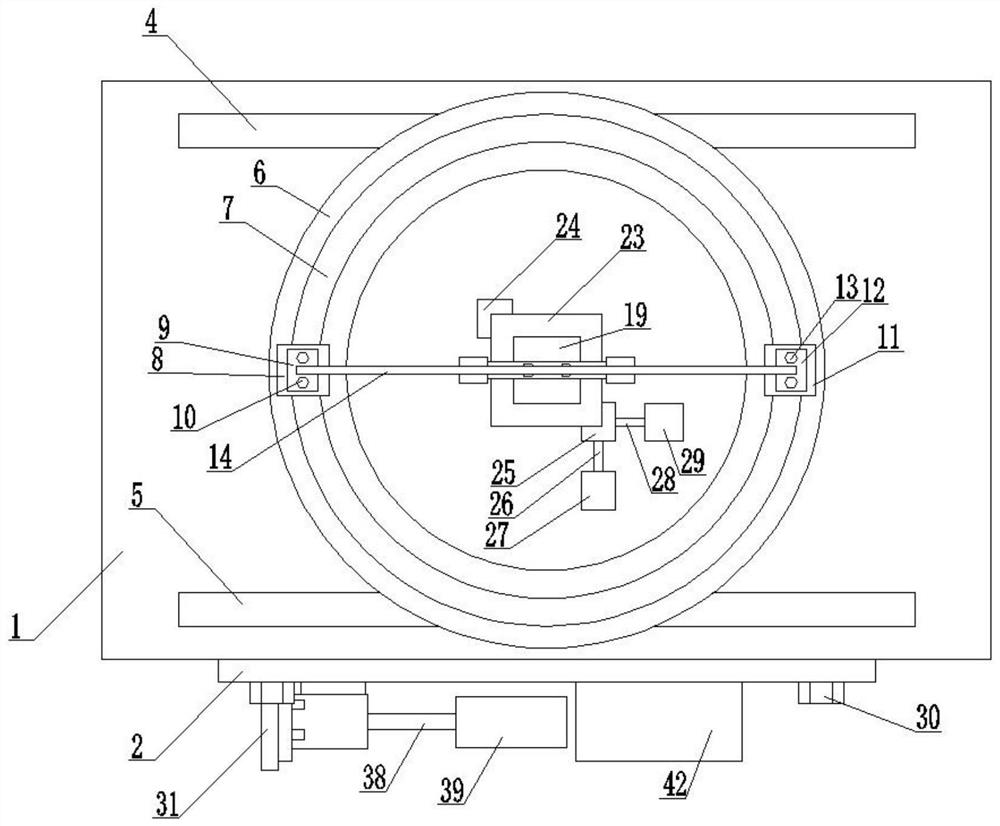

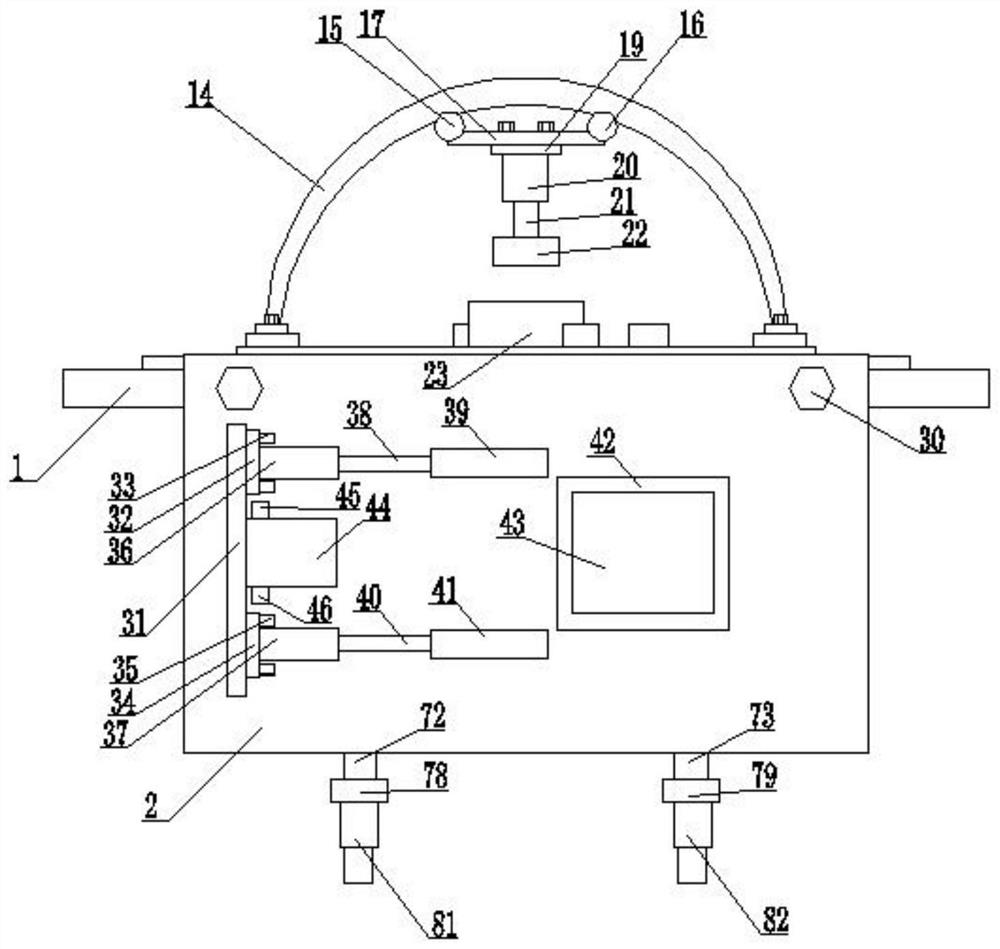

[0026] The present invention is described in detail below in conjunction with accompanying drawing:

[0027] refer to Figure 1 to Figure 8 A stamping die for parts production provided by the present invention includes a base plate 1, an auxiliary plate 2, and an action box 3. The right side of the base plate 1 is fixedly connected to the upper end of the auxiliary plate 2 through a fourth series of bolt groups 30, The lower side of the base plate 1 is provided with an action box 3, and the top surface of the base plate 1 is provided with a front guide rail 4 and a rear guide rail 5 successively from front to back. The bottom of the positioning ring 6 is matched, and the top of the limiting ring 6 is provided with a circular groove 7, and the left and right sides of the circular groove 7 are respectively in contact with the left matching block 8 and the right matching block 11. The left matching The top of the block 8 is fixed with the left connecting piece 9 through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com