High-temperature-resistant emergency plugging material and application thereof

A leakage plugging material and high temperature resistance technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems such as the inability to meet the technical requirements of deep high temperature leakage plugging and the high temperature resistance performance of the leakage plugging material is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

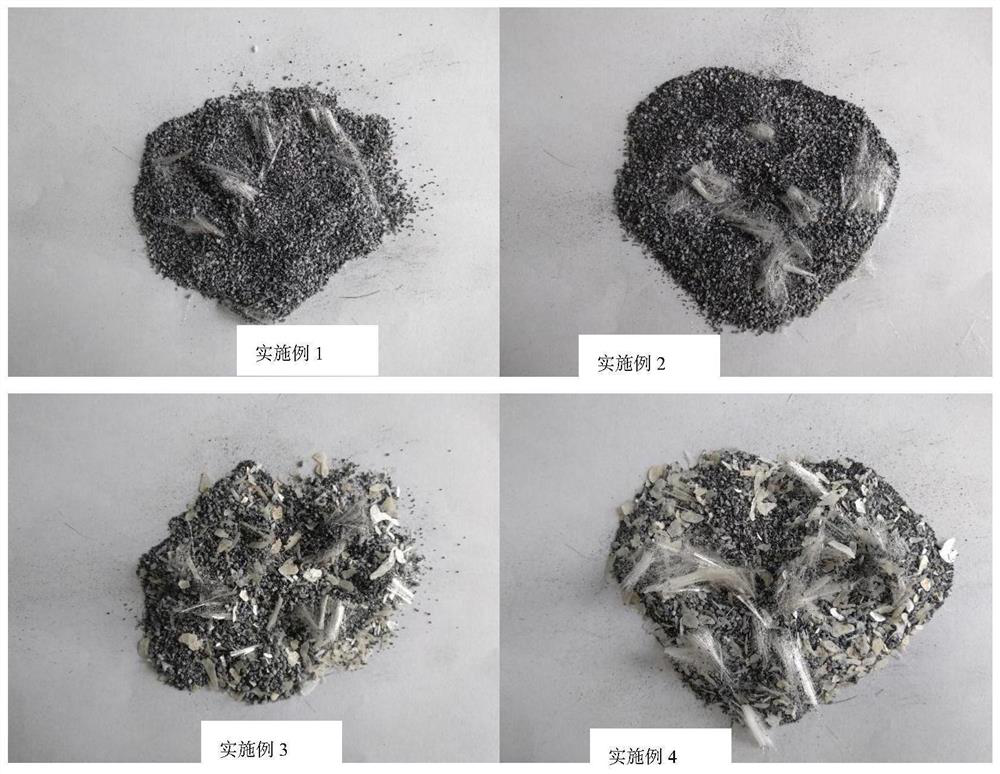

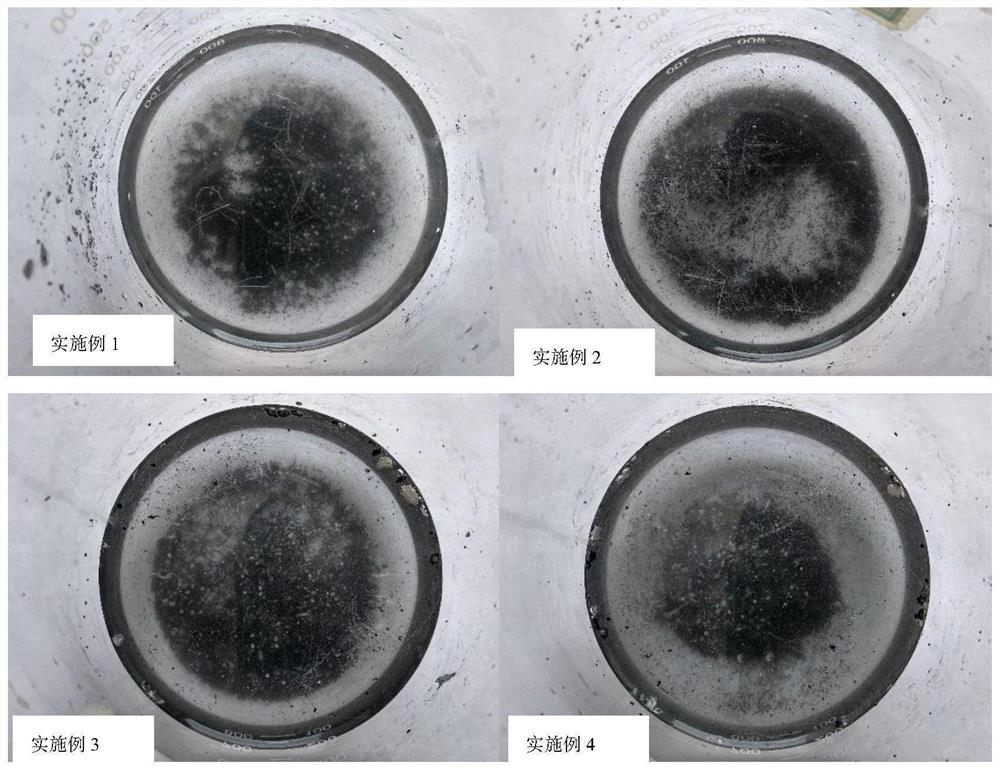

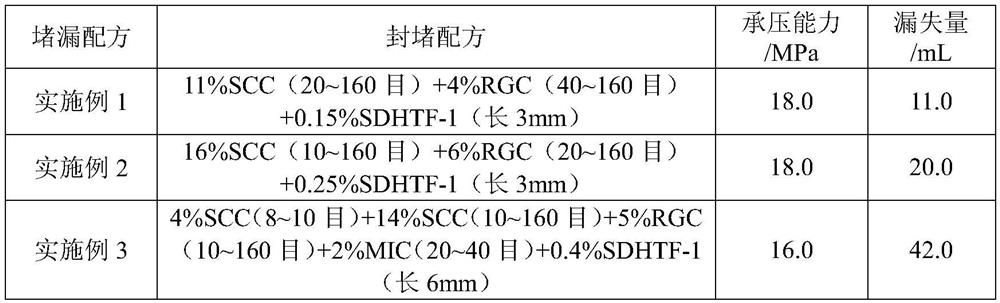

Embodiment 1

[0038] The prepared "small leak" anti-high temperature emergency plugging formula includes the following components by mass:

[0039] 11 parts of rigid calcium carbonate particles (20-160 mesh), 4 parts of elastic graphite particles (40-160 mesh), 0.15 parts of high temperature resistant fiber (3mm).

Embodiment 2

[0041] The prepared "medium leakage" anti-high temperature emergency plugging formula includes the following components by mass:

[0042] 16 parts of rigid calcium carbonate particles (10-160 mesh), 6 parts of elastic graphite particles (20-160 mesh), 0.25 parts of high temperature resistant fiber (3mm).

Embodiment 3

[0044] The prepared "big leak" anti-high temperature emergency plugging formula includes the following components by mass:

[0045] 4 parts of rigid calcium carbonate particles (8-10 mesh), 14 parts of rigid calcium carbonate particles (10-160 mesh), 5 parts of elastic graphite particles (10-160 mesh), 2 parts of mica flakes (20-40 mesh), High temperature fiber (6mm) 0.4 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com