Etching solution composition for silver-containing metal layer

A composition and etching solution technology, applied in the field of etching solution compositions for silver-containing metal films, can solve problems such as generation of debris, increase metal stability, and decrease in etching performance of etchants, and achieve suppression of damage and excellent etching properties. , Minimize bad deviation and the effect of debris or precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

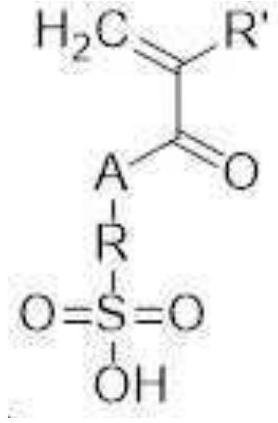

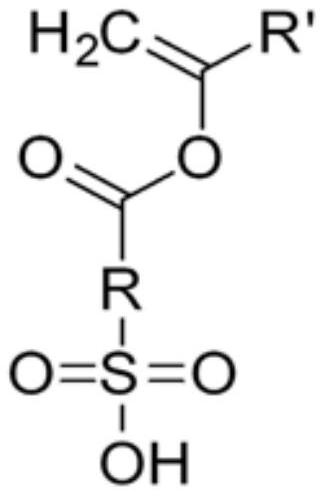

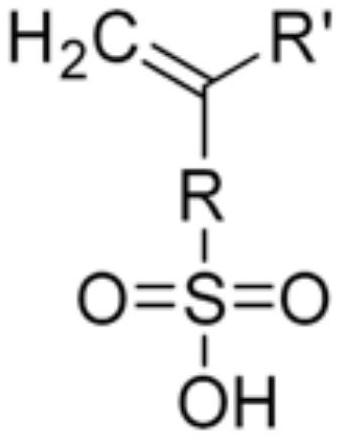

Method used

Image

Examples

Embodiment 1 to 13 and comparative example 1 to 2

[0073] Each component was mixed with the content (unit: part by weight) in following Table 2, and the etchant composition for metal films containing silver or a silver alloy was prepared.

[0074] 【Table 2】

[0075]

experiment example 1

[0076] Experimental example 1: Etching characteristic evaluation

[0077] In order to evaluate the etching performance of the prepared etching solution composition, a triple film of ITO / Ag / ITO was sequentially formed on a glass plate (100mm×100mm), and the thickness of each layer was and After that, a photolithography process is performed to form patterns.

[0078] At this time, the etching process used a jet etching test equipment (ETCHER (TFT), SEMES), and the temperature of the etching solution composition in the etching process was set to about 35° C. The etching time is set to be performed for 50 to 100 seconds.

[0079] After etching, SEM (S-4800, Hitachi Corporation) was used on the etched cross section of the ITO / Ag / ITO triple film to evaluate the etching characteristics, and the degree of occurrence of bias, lower film damage, debris, and precipitates was observed.

[0080] On the one hand, evaluate the etch rate with Ag single film, specifically, use ellipsomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com