Construction machinery control cabinet

A technology for construction machinery and control cabinets. It is applied in the direction of pull-out switch cabinets, switchgear, electrical components, etc. It can solve problems such as equipment failure, falling and jamming in the moving slot of the drawer, and inconvenient movement of the drawer, so as to achieve improvement. Ability to move, improve stretching effect, avoid wear and tear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

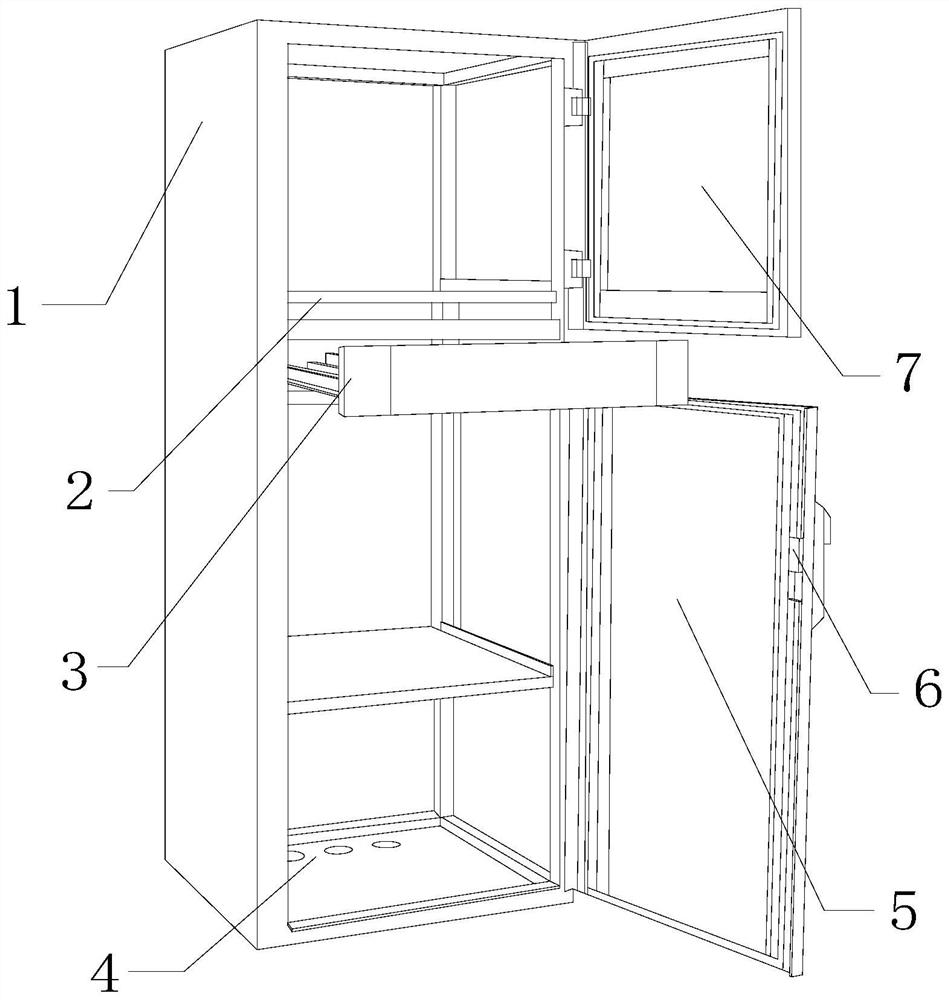

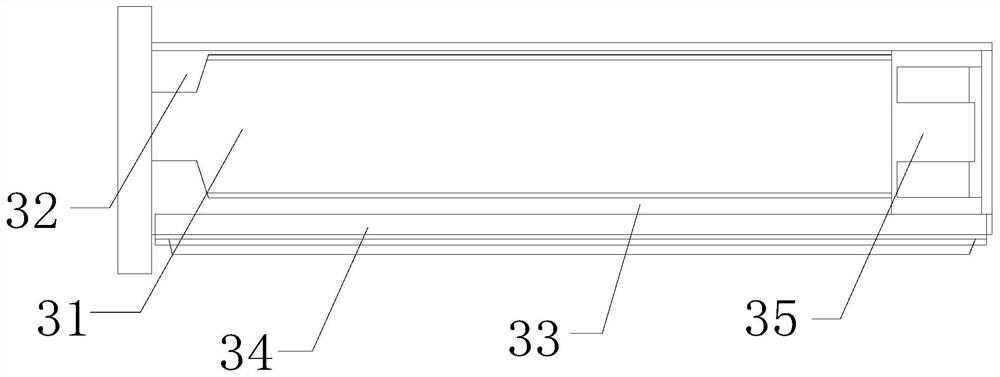

[0025] Such as Figure 1-Figure 4 Shown:

[0026] The invention provides a control cabinet for construction machinery, the structure of which includes a control cabinet box 1, a placement board 2, a drawer 3, a hollow bottom plate 4, a lower cabinet door 5, a lock 6, an upper cabinet door 7, and the upper cabinet door 7 The hinge is connected to the top of the control cabinet 1, the placement plate 2 is bolted to the top of the drawer 3, the hollow bottom plate 4 is embedded and connected to the bottom of the control cabinet 1, and the lock 6 is nested and connected to the lower cabinet door 5 At the side end, the lower cabinet door 5 is hinged to the position below the control cabinet 1, and the drawer 3 is movably engaged in the middle and upper section inside the control cabinet 1. The drawer 3 mainly includes a drawer box 31, a guide rail baffle 32, Side guide rail 33, sliding mechanism 34, auxiliary pusher 35, described auxiliary pusher 35 is embedded and connected to th...

Embodiment 2

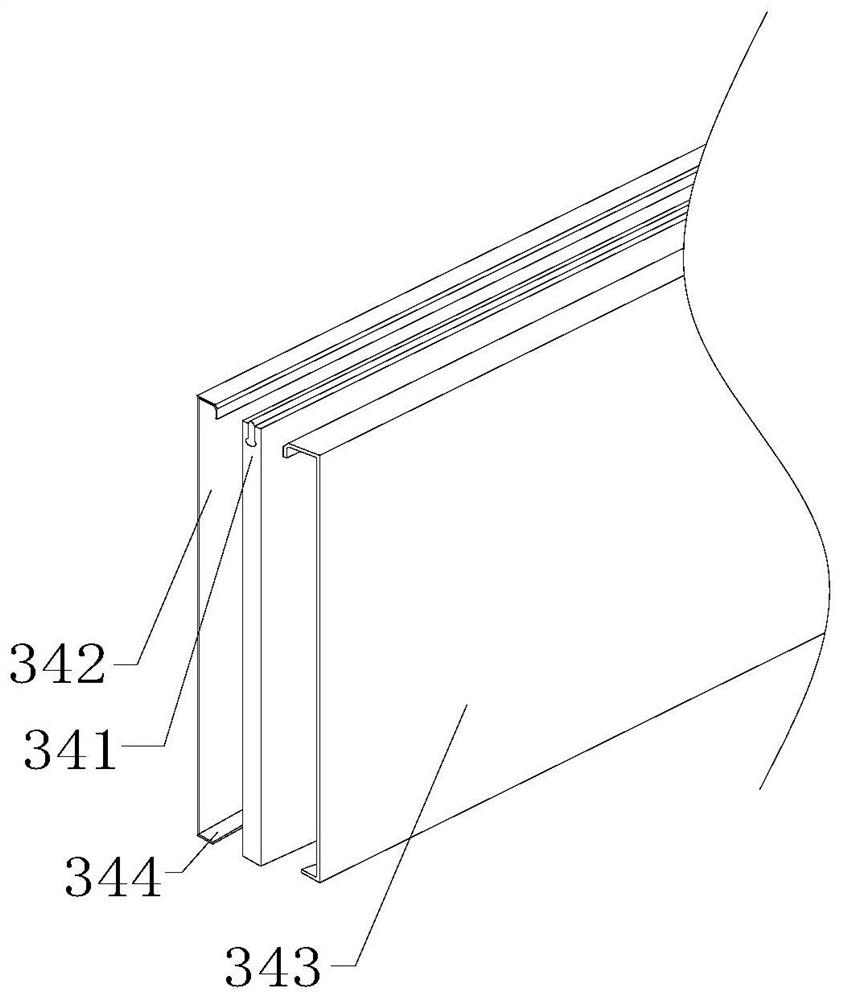

[0032] Such as Figure 5-Figure 8 Shown:

[0033]The present invention provides a construction machinery control cabinet. The auxiliary pusher 35 mainly includes a pad 351, an extension device 352, a shaft plate 353, a shaft rod 354, an insert block 355, a stopper 356, and a spring rod 357. The extension device 352 is nested and connected between the pads 351, the extension device 352 is attached to the front of the shaft 354, the elastic rod 357 is embedded and connected to the rear of the insert 355, and the shaft plate 353 is bolted to the side of the shaft 354 Square, the shaft 354 is fixedly connected under the plug 355, the elastic rod 357 is riveted to the front end of the stopper 356, the stopper 356 is connected with the shaft 354, and the auxiliary pusher 35 has a stepped structure , and the stopper 356 at the upper end is provided with three elastic rods 357, which are arranged and installed at the front end of the stopper 356. The elastic rods 357 can assist the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com