Desktop dust collector

A technology for vacuum cleaners and dust cups, which is applied in the installation of vacuum cleaners, suction filters, electrical equipment, etc., can solve the problems of limited performance of desktop vacuum cleaners, low utilization of space in the shell, and bloated overall structure of the product. The effect of good heat dissipation and less contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

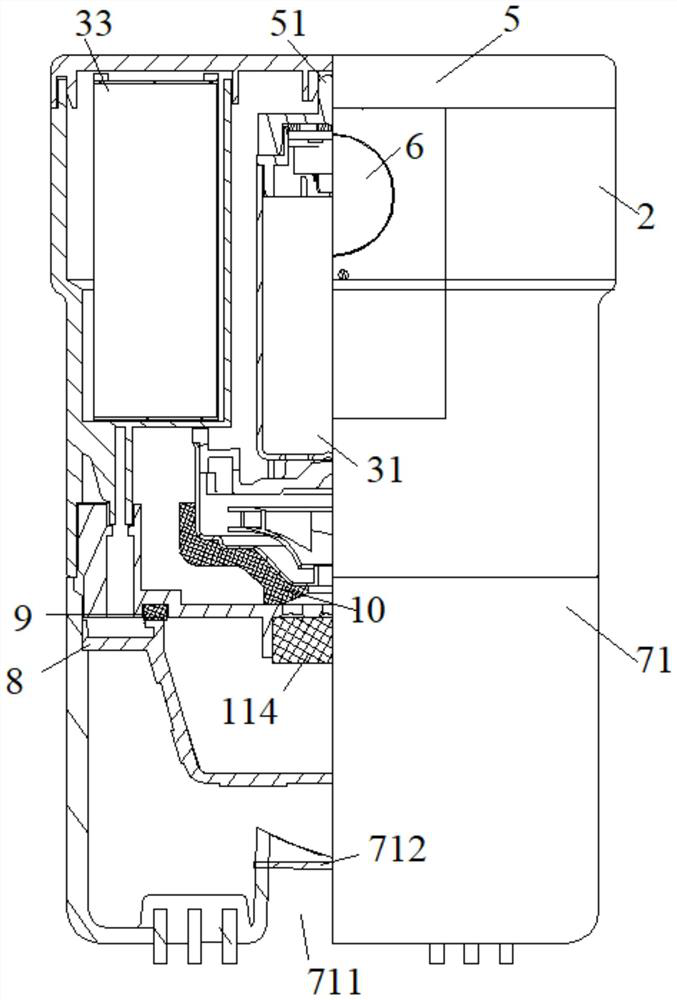

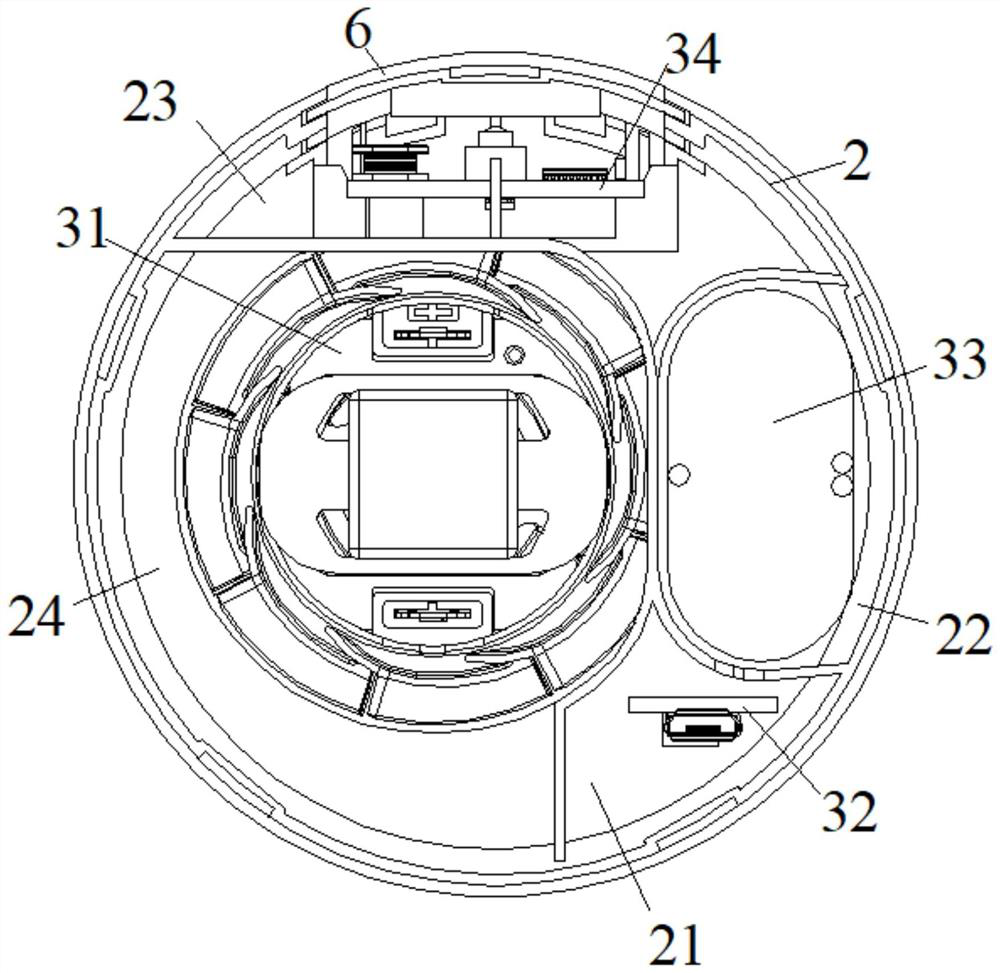

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

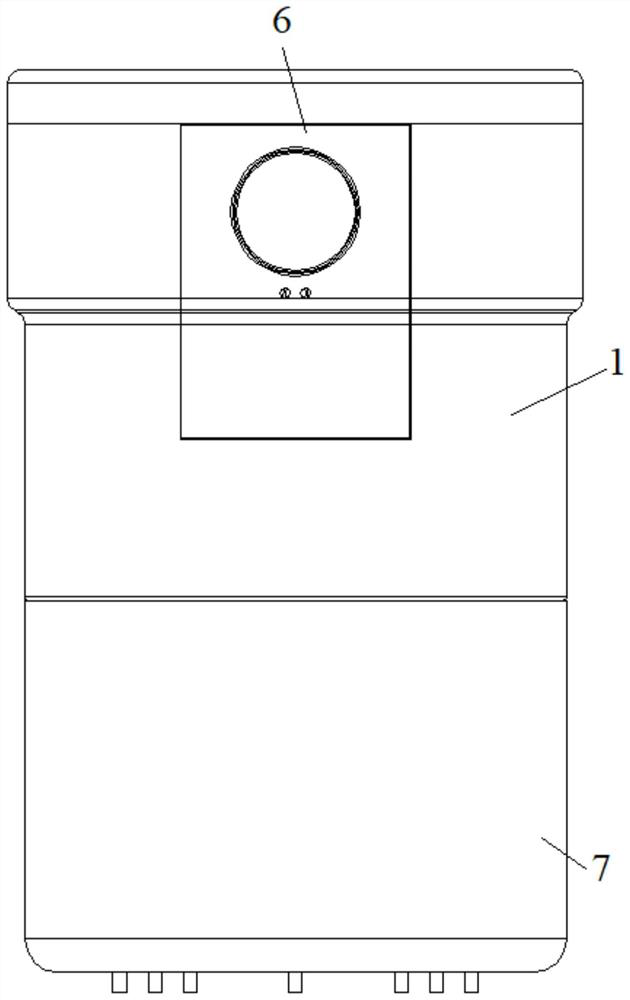

[0030] see Figure 1 to Figure 4 As shown, a desktop vacuum cleaner includes a casing 2 and a vacuum cleaner main body 1 disposed in the casing 2. The vacuum cleaner main body 1 includes a vacuum cleaner motor 31, a dust collection assembly 7, and an auxiliary device electrically connected to the vacuum cleaner motor 31. The vacuum cleaner motor 31 has an air suction port and an air exhaust port, the air suction port is connected to the dust collecting assembly 7; the vacuum clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com