Wind shield for inner fan structure three-phase asynchronous motor

A three-phase asynchronous, electric motor technology, applied in the field of electric motors, can solve the problems of no good heat dissipation effect, unreasonable air passage structure, single ventilation structure, etc., and achieve the effect of improving heat dissipation effect, reasonable structure and smooth air passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

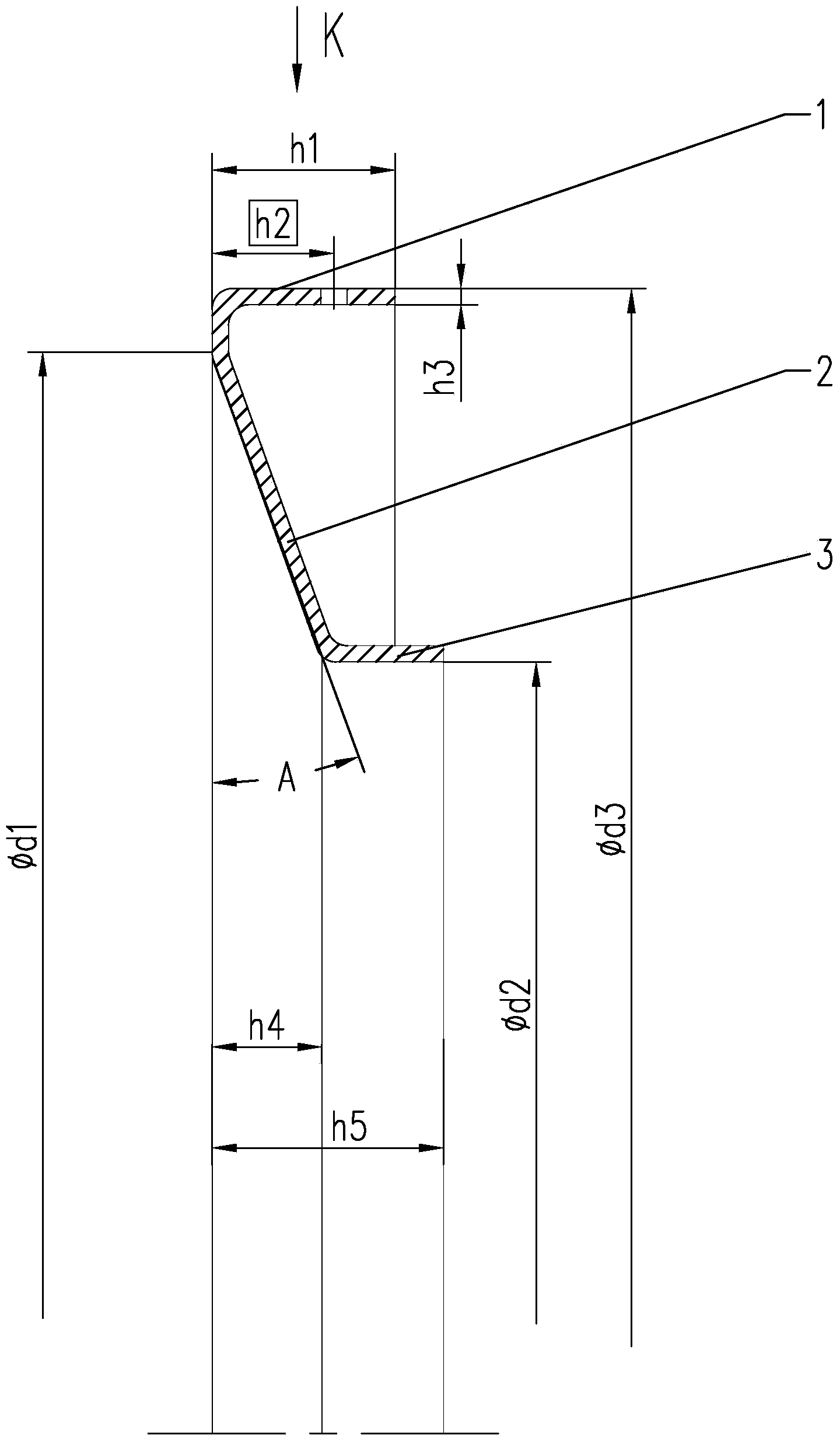

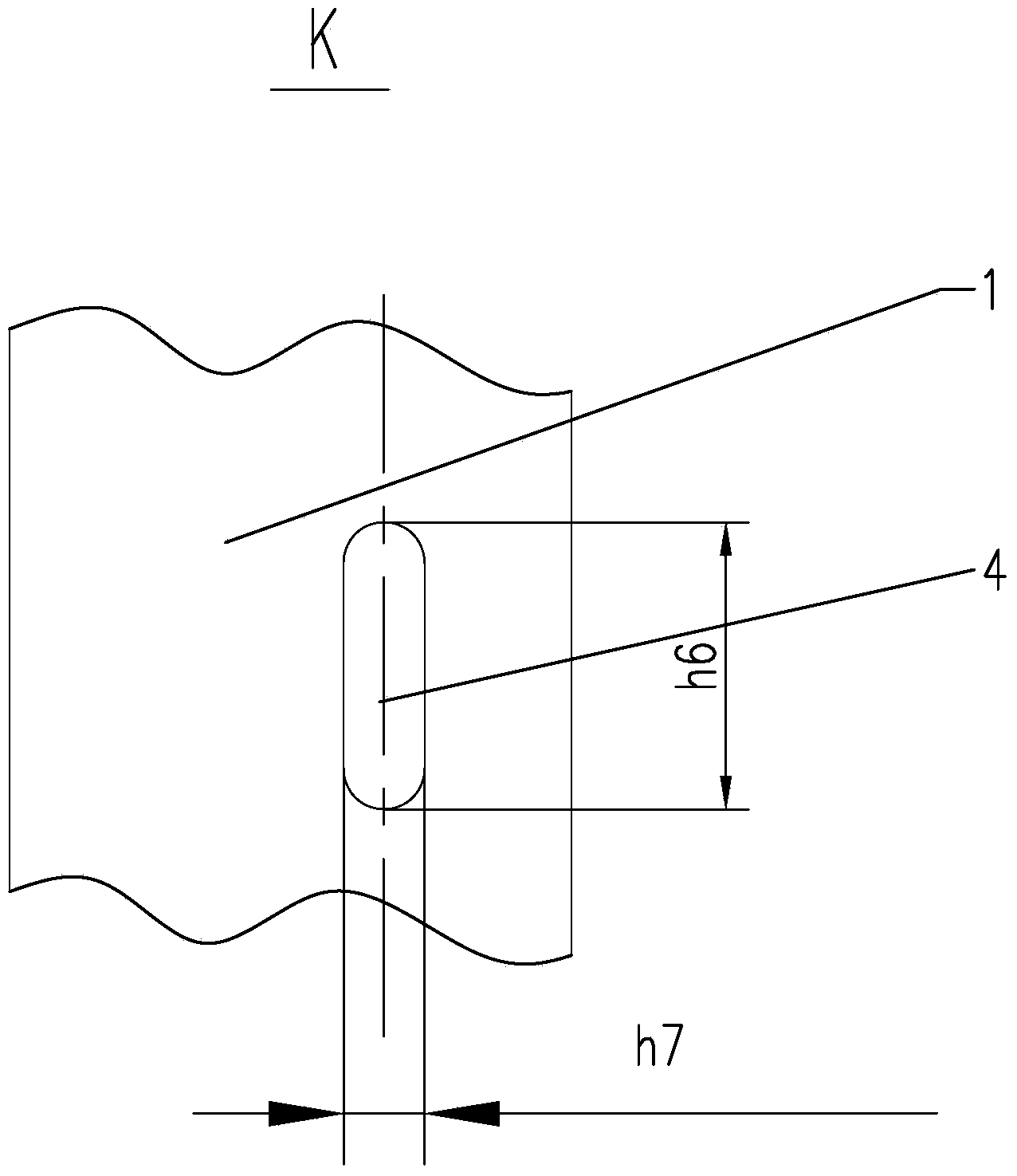

[0018] Such as Figure 1~2 As shown, the present invention mainly includes an outer ring 1 and an inner ring 3 , and the inner ring 3 is located in the outer ring 1 .

[0019] The outer ring 1 and the inner ring 3 are connected into one body through the air guide ring 2 at the left end, the air guide ring 2 is trumpet-shaped, and the diameter of the air guide ring 2 gradually decreases from left to right. The large-diameter opening end of the air guiding ring 2 is the air guiding outlet, and the small-diameter opening end of the air guiding ring 2 is the air guiding inlet. The small-diameter open end of the wind guide ring 2 is the same diameter as the inner ring 3 .

[0020] The included angle A between the side wall of the wind guiding ring 2 and the vertical line is 0-90°.

[0021] The outer surface of the outer ring 1 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com