Nuclear power station large horizontal centrifugal pump king bolt stretching labor-saving device

A nuclear power plant, large-scale technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of increasing the collective dose value of maintenance personnel, prolonging maintenance time, etc., and achieve the effects of improving maintenance efficiency, reducing labor intensity, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

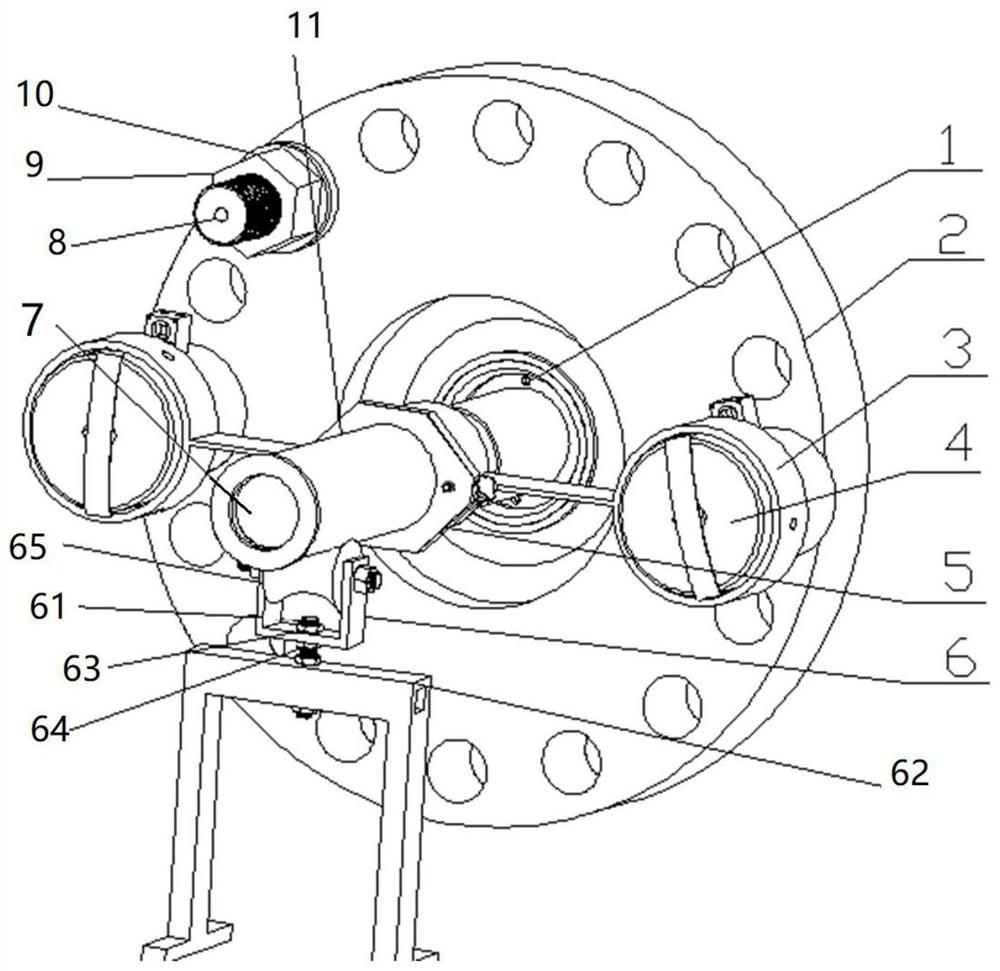

[0033] Such as figure 1 As shown, the large cover 2 of the pump body is a circular plate structure, and 16 mounting holes are evenly processed on the circumference, and 16 main bolts 8 are arranged through the main bolt nuts 9 and the main bolt gaskets 10 . A shaft hole is machined in the center of the pump body cover 2, and the pump shaft is installed in the hole.

[0034] The balance drum 1 is fixed on the pump shaft and fits with the large cover 2 of the pump body in a gap to connect the inlet and outlet of the pump body to balance the axial force of the rotor.

[0035] The stretching labor-saving device in the present invention will remove the main bolt 3 from the large cover 2 of the pump body.

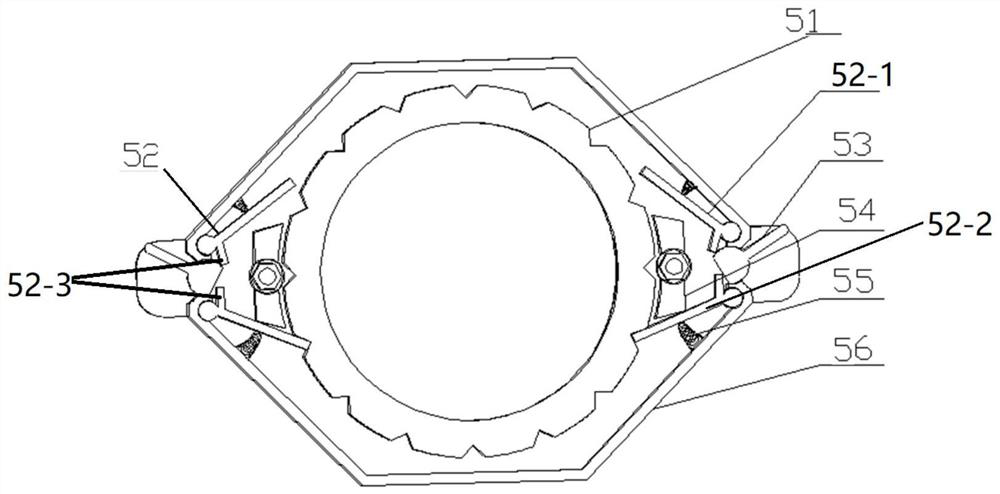

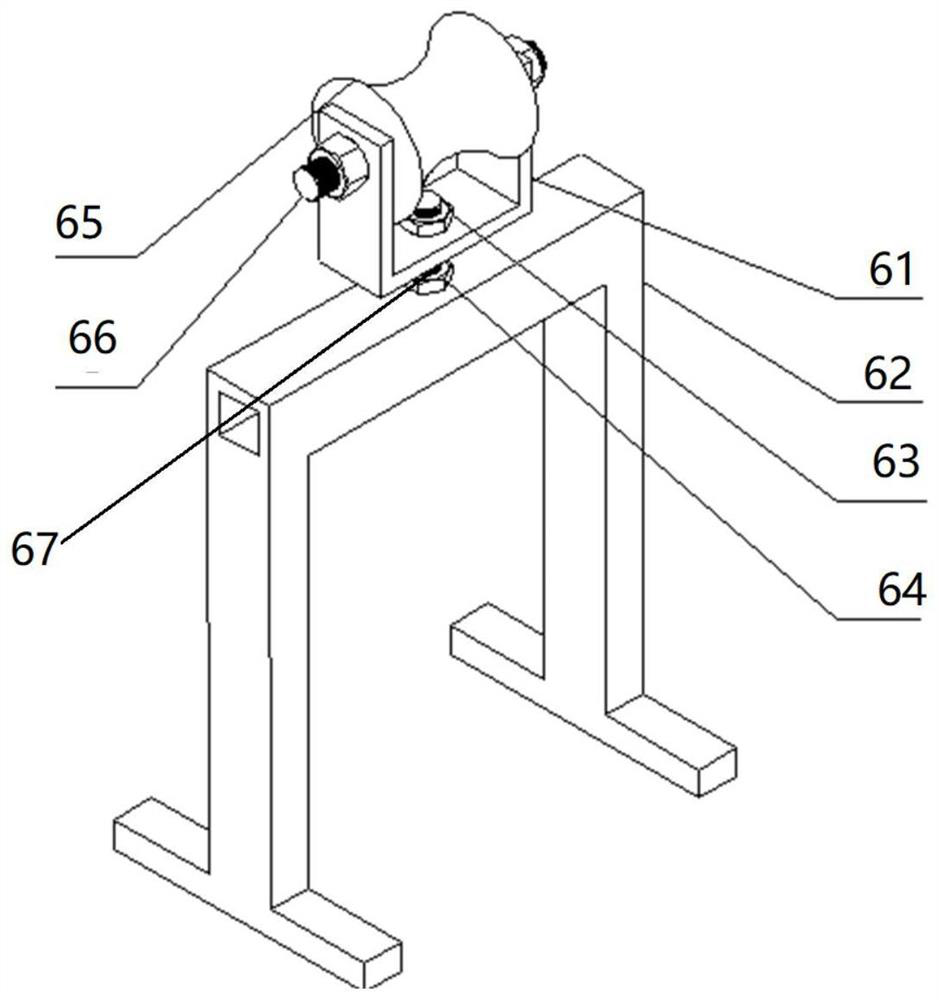

[0036] The stretching labor-saving device includes a sleeve 11 connected to the pump body cover 2 and set on the outside of the pump shaft, a ratchet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com