Position-adjustable front/side combined film pressing mechanism

A technology for laminating mechanism and adjusting structure, which is applied in the field of laminating equipment and laminating mechanism, which can solve the problems of poor film consistency, low film lamination efficiency, and low degree of automation, so as to improve film lamination quality, increase film lamination efficiency, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

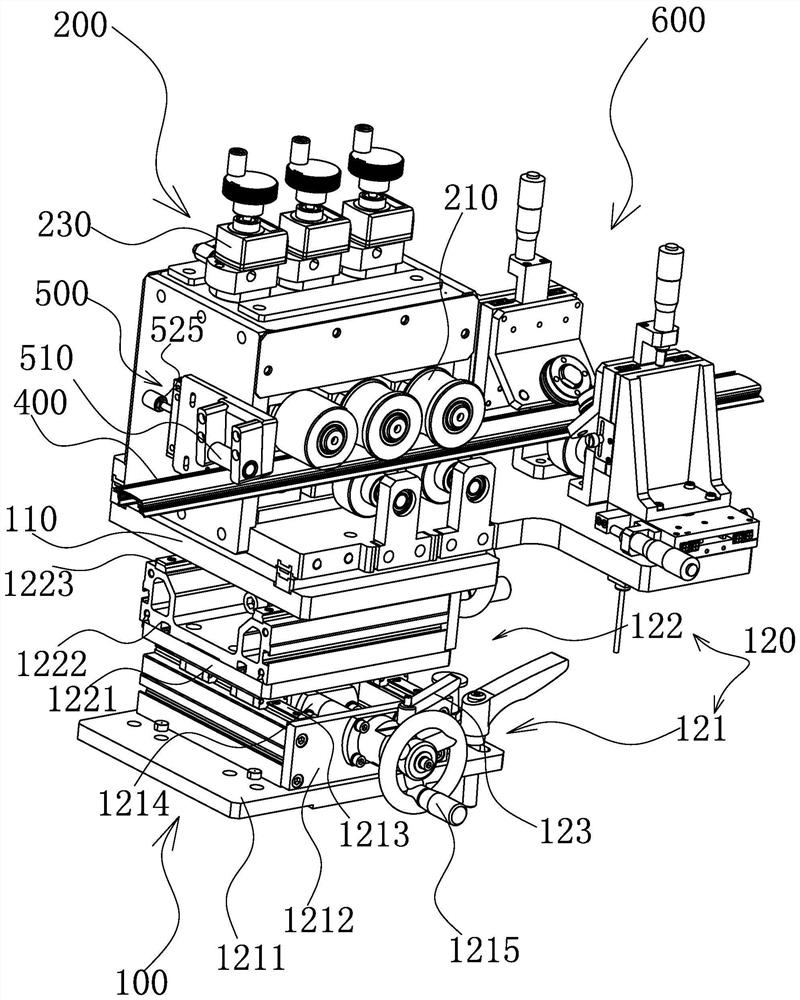

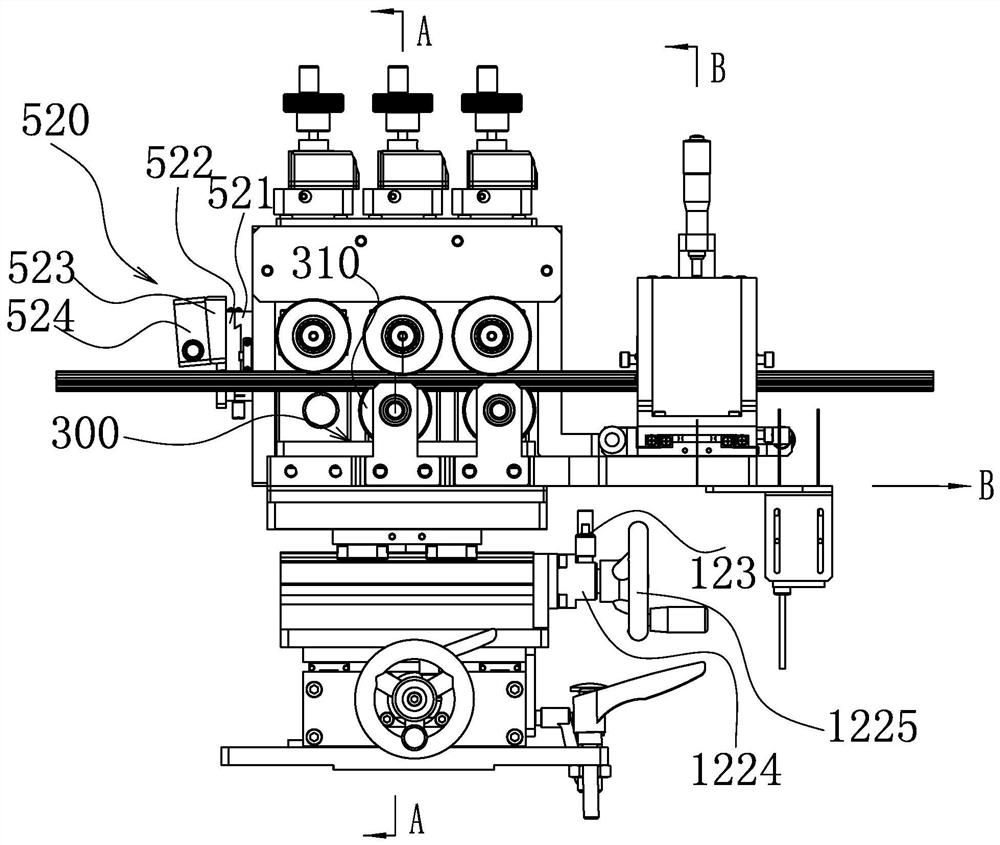

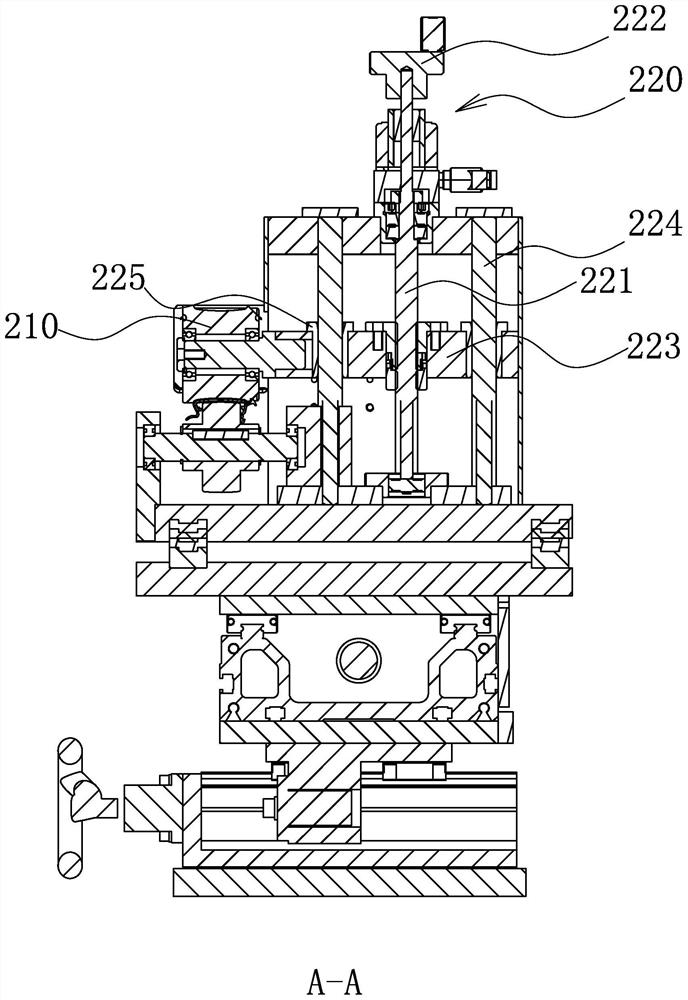

[0033] like Figure 1 to Figure 4 As shown, the present invention provides a position-adjustable front / side combination laminating mechanism, comprising: a base 100, on which a mounting table 110 is arranged; a pressing mechanism 200, mounted on the mounting table 110, and pressing down The mechanism 200 includes several pressing rollers 210, and several first adjustment structures 220 for adjusting the upper and lower positions of the corresponding pressing rollers 210; the supporting mechanism 300 is installed on the installation table 110, and the supporting mechanism 300 includes several supporting rollers 310, Wherein, the lower pressure roller 210 and the support roller 310 are distributed up and down, and between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com