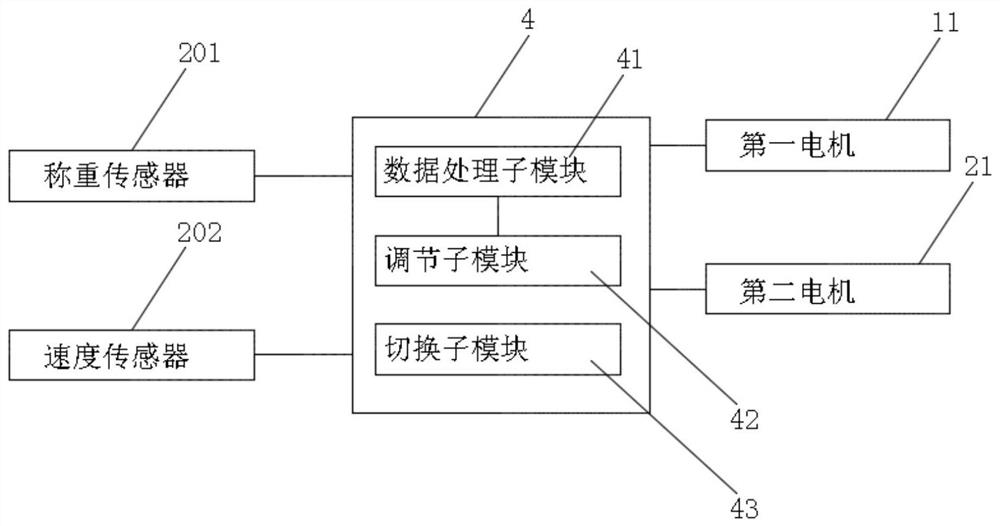

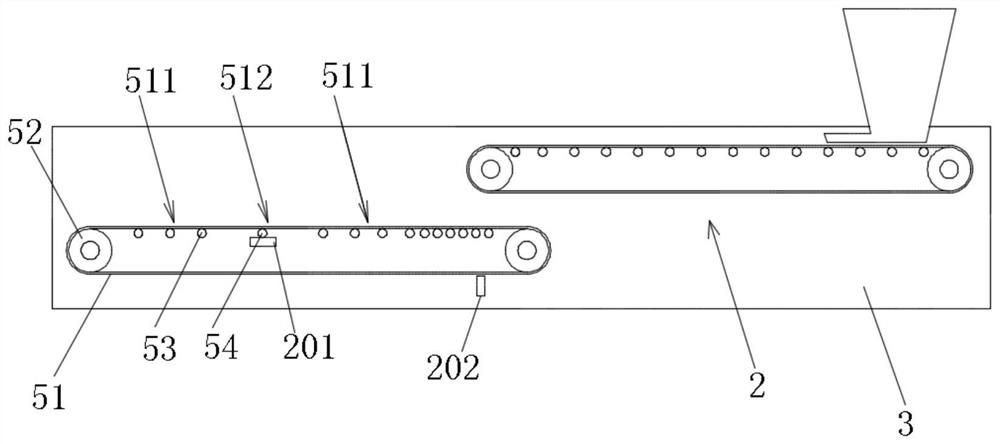

A control system for controlling the frequency of metering belts in different areas in a double-layer structure belt

A technology of sub-regional control and control system, applied in the conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problem of tare weight deviation is difficult to avoid, and achieve the effect of preventing jitter, reducing measurement errors, and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0068] Experimental example 1 adopts the control mode of the speed regulation sub-module 41, the tare weight deviation of the metering belt 2 is 1kg / m, the given flow rate is 10t / h, and the given flow rate is 8≤Q s1 ≤40t / h, located in the second flow range, the metering belt 2 runs at 30Hz, and the actual speed at 30Hz is approximately equal to: 0.15*30 / 50=0.09m / s.

[0069] When there is no tare deviation, according to formula (3), Q 0s1 =(P 2 -P 3 ) s1 *0.09*3.6=10, calculated (P 2 -P 3 ) s1 = 30.86 kg / m.

[0070] When there is a tare weight deviation, according to formula (4), Q 0xs1 =(30.86-1)*0.09*3.6, calculated Q 0xs1 =9.675t / h;

[0071] According to formula (5) δ s1 =100%*(9.675-10) / 10, calculated, δ s1 = -3.25%;

[0072] It can be seen that the actual feed flow rate of the metering belt 2 in Experimental Example 1 is 9.675t / h, and the deviation is -3.25%.

[0073] After changing the control mode in combination with Comparative Example 1 and Experimental Ex...

experiment example 2

[0079] Experimental example 2 adopts the control mode of the speed regulation sub-module 41, the tare weight deviation of the metering belt 2 is 1kg / m, the given flow rate is 5t / h, and the given flow rate is 0≤Q s2 <8t / h, located in the first flow range, the metering belt 2 runs at 15Hz, and the actual speed at 15Hz is approximately equal to: 0.15*15 / 50=0.045m / s.

[0080] When there is no tare deviation, according to formula (3), Q 0s2 =(P 2 -P 3 ) s2 *0.045*3.6=5, calculate (P 2 -P 3 ) s2 = 30.864 kg / m.

[0081] When there is a tare weight deviation, according to formula (4), Q 0xs1 =(30.864-1)*0.045*3.6, calculated Q 0xs1 =4.838t / h;

[0082] According to formula (5) δ s1 1=100%*4.838-5) / 5, calculated, δ s1 = -3.24%;

[0083] It can be seen that the actual feeding flow rate of experimental example 1 is 4.838t / h, and the deviation is -3.24%.

[0084] After changing the control mode in combination with Comparative Example 1 and Experimental Example 1, the measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com