a gas explosion device

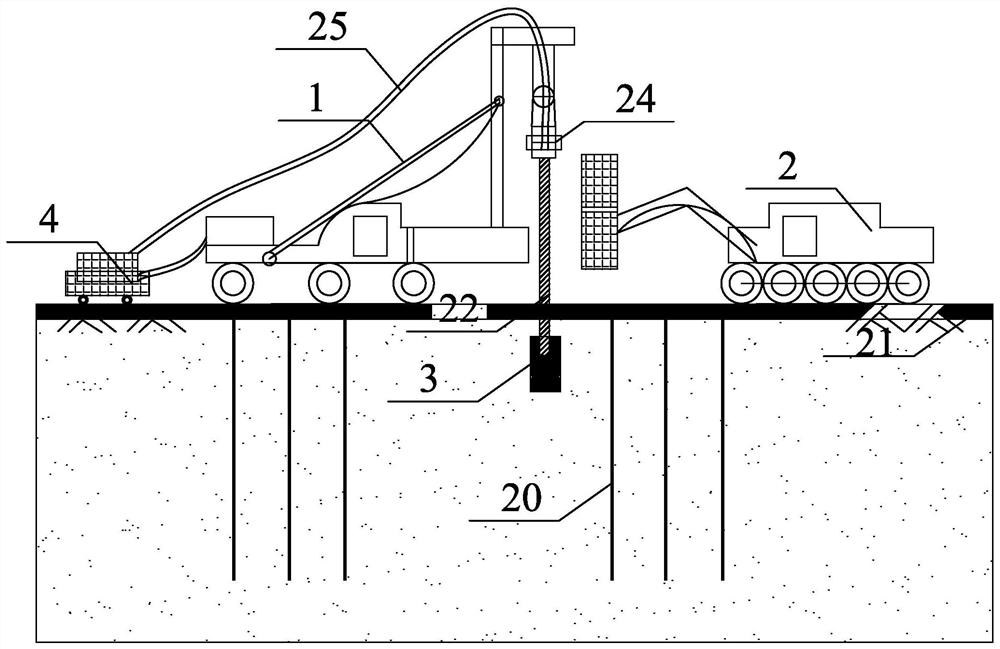

A technology of air explosion and air cylinder, which is applied in the field of dynamic compaction to deal with saturated soft soil foundation, which can solve the problems of poor compaction effect, difficult drainage, lack of drainage channels, etc., so as to speed up drainage and consolidation speed and reduce soil after-work Effect of creep, deepening process depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

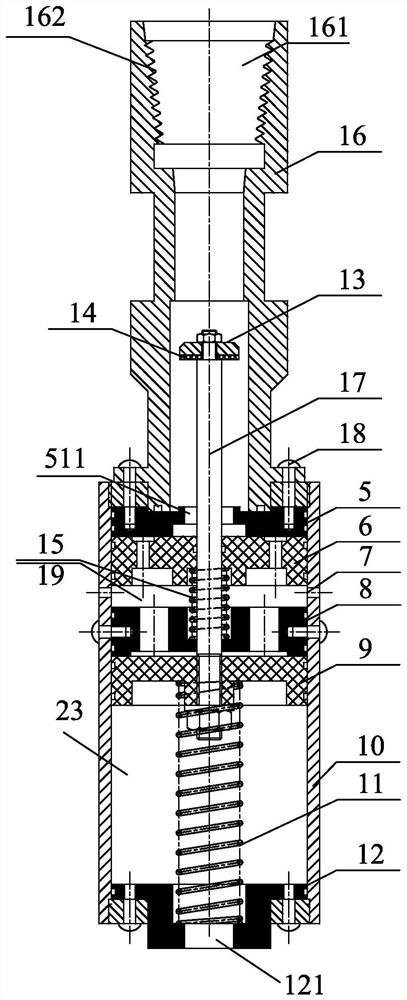

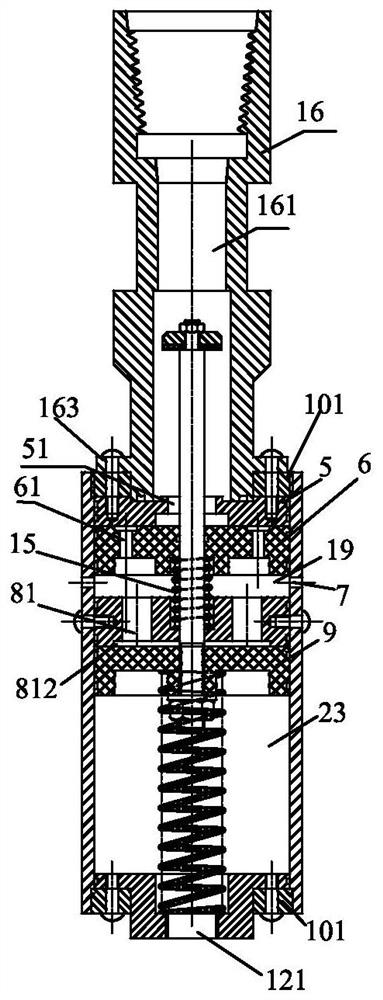

[0047] see figure 2 , a gas explosion device, comprising a cylinder, the cylinder comprises a cylinder, a piston, a piston rod; the upper end of the cylinder 10 is provided with a cylinder front cover 5, the lower end is provided with a cylinder rear cover 12, and the cylinder middle ring 8 is provided inside; Cylinder front cover 5, cylinder back cover 12, cylinder middle ring 8 are respectively fixed with described cylinder barrel 10; In described cylinder barrel 10, the cavity between described cylinder front cover 5 and cylinder middle ring 8 forms gas explosion The chamber 19, the cavity between the cylinder middle ring 8 and the cylinder rear cover 12 constitutes an energy storage chamber 23; the cylinder wall at the lower part of the gas explosion chamber 19 is provided with an internally and externally connected gas explosion hole 7;

[0048] Described piston comprises pilot piston 6 and energy storage piston 9; Described pilot piston 6 moves up and down in the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com