Cushion stone shaping mold

A technology for shaping molds and pad stones, which is applied in the direction of formwork/formwork components, formwork/formwork/working frames, erection/assembly of bridges, etc., and can solve the deformation and displacement of formwork, grout leakage, and easy deviation of anchor bolt holes in supports and other problems to achieve the effect of ensuring the molding quality and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

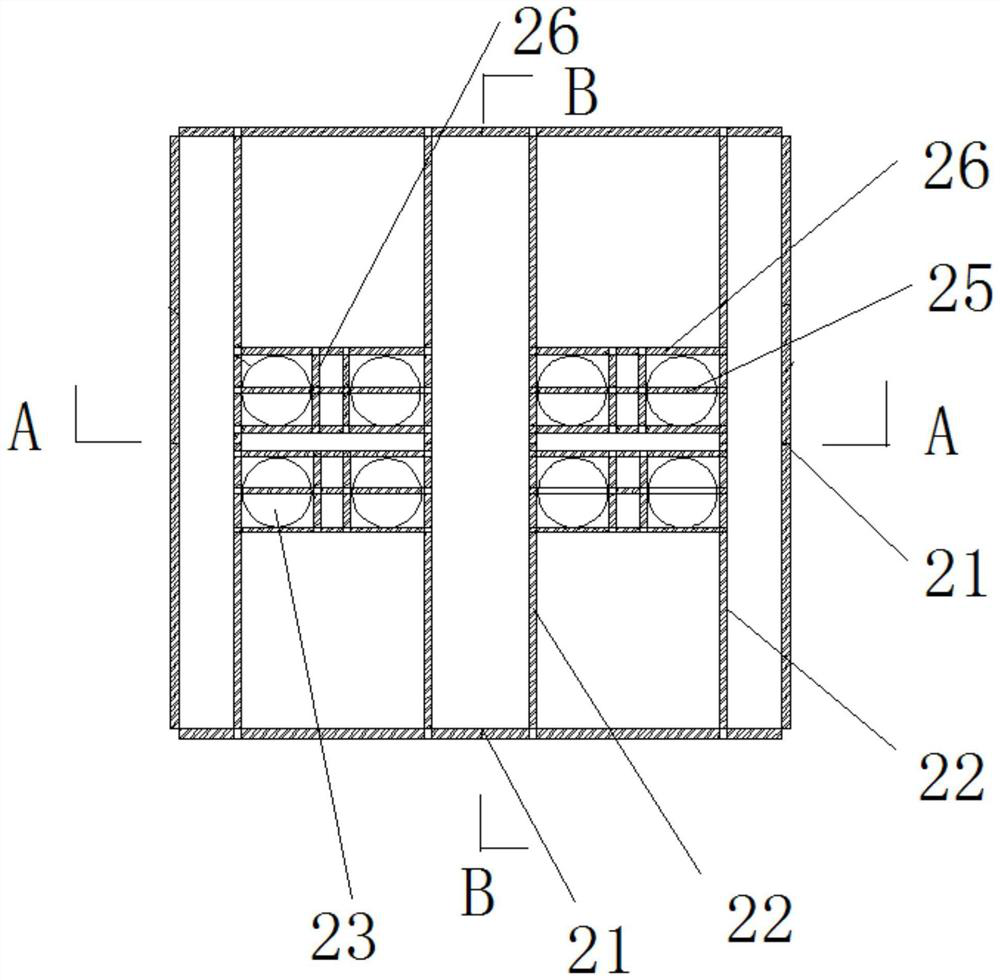

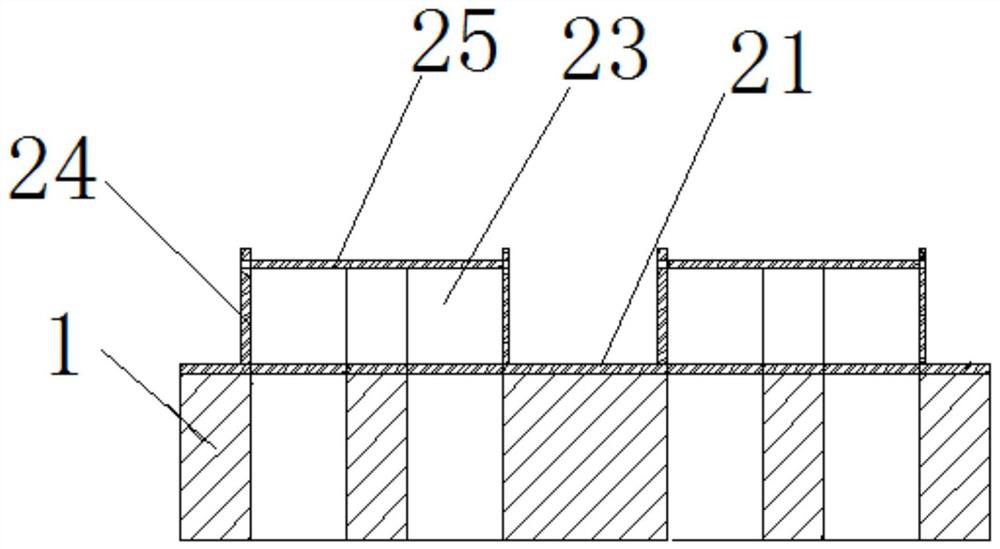

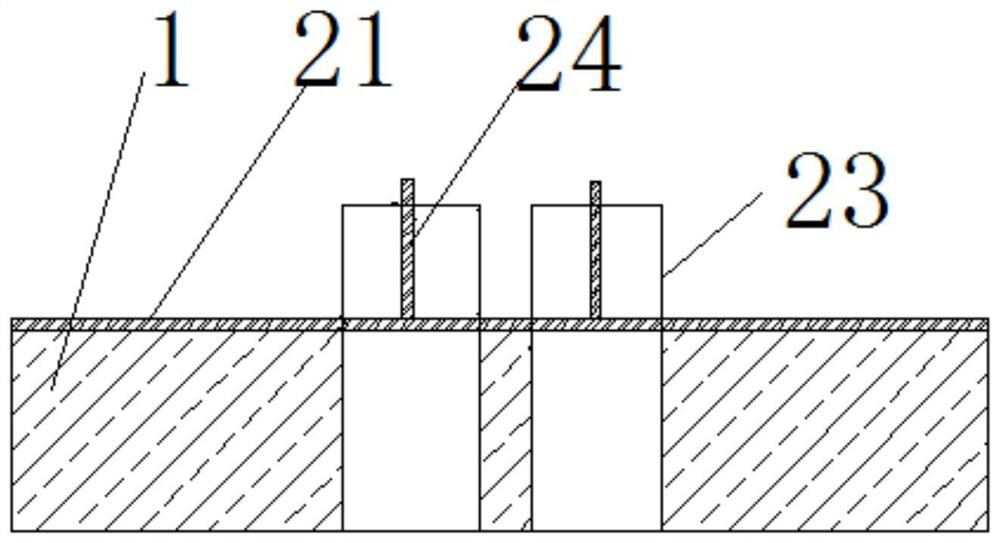

[0021] Such as figure 1 As shown, in this embodiment, a pad stone setting mold includes a limiting structure and several templates 1 arranged on the limiting structure and used to surround and form a concrete pouring space. The limiting frame 21 with the same cross-sectional profile, the template 1 is a steel template.

[0022] Using the limit structure as the positioning and installation reference of the formwork 1, the formwork 1 is installed on the limit structure, the formwork 1 surrounds and forms a space for pouring concrete, and the work of pouring concrete is performed after the reinforcement cage is installed. After the concrete is formed, the template 1 and the limiting structure are removed. In this scheme, due to the use of steel formwork, when pouring concrete, the steel formwork can resist the impact of concrete and avoid deformation, which is conducive to ensuring the shape accuracy of formwork 1 itself. Compared with wood formwork, the strength and surface qua...

Embodiment 2

[0025] Such as figure 1 , figure 2 As shown, on the basis of the above embodiments, in this embodiment, the position-limiting structure includes several steel pipe mounting brackets 22 arranged in the position-limiting frame 21, and the steel pipe mounting brackets 22 are installed with The steel pipe 23 of reserved hole.

[0026] The steel pipe 23 can extend into the space formed by the template 1. When pouring concrete, since the steel pipe 23 occupies part of the space, after the concrete is formed, the steel pipe 23 can be taken out to form a reserved hole.

[0027] Utilizing the steel pipe installation bracket 22 as the basis for installing the steel pipe 23 can control the position of the steel pipe 23 to maintain the position required by the design, can save the steps of positioning and installing the steel pipe, and is conducive to improving construction efficiency, and multiple constructions can ensure that the steel pipe The position is always consistent, ensuring...

Embodiment 3

[0036] On the basis of the above embodiments, in this embodiment, the template 1 and the limiting frame 21 are connected by bolts. This is beneficial to facilitate construction. After the pad stone is formed, the formwork 1 and the limiting structure are easily removed by loosening the bolts, so as to avoid deformation of the formwork 1 and the limiting frame during the demoulding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com