System of increasing yield of coal seam gas by mixing with hot air proppant, and its working method

A working method and proppant technology, applied in mixers, chemical instruments and methods, and earthwork drilling and production, can solve problems such as low economic efficiency, high cost, and large resource consumption, and achieve increased production, high conductivity, and The effect of improving the resolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

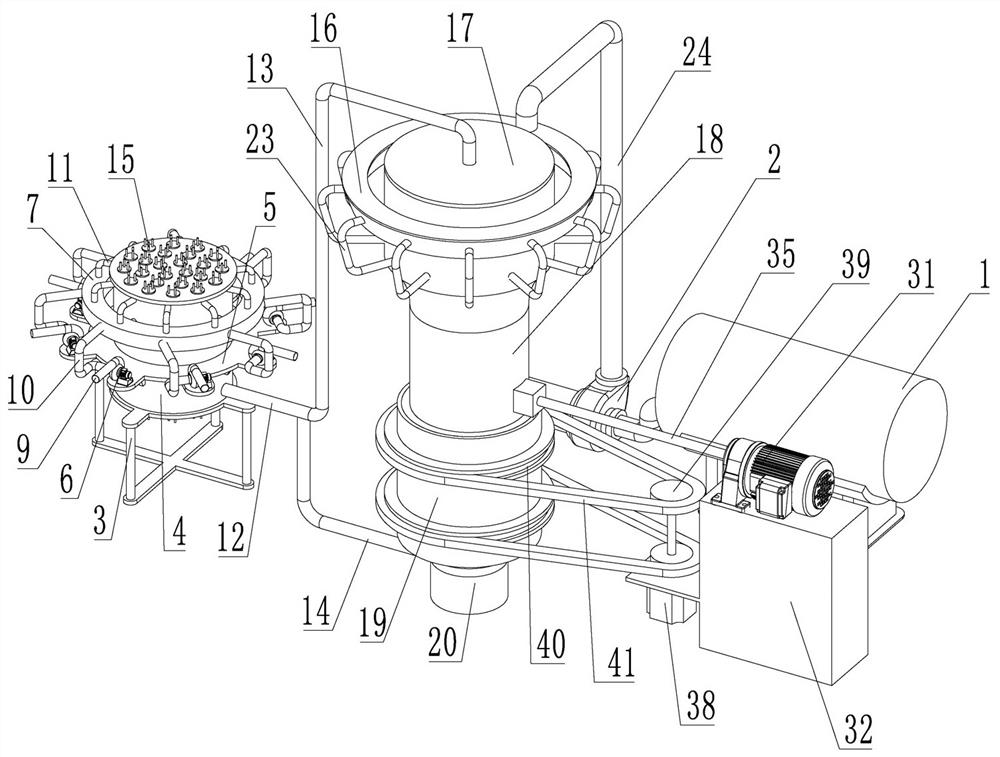

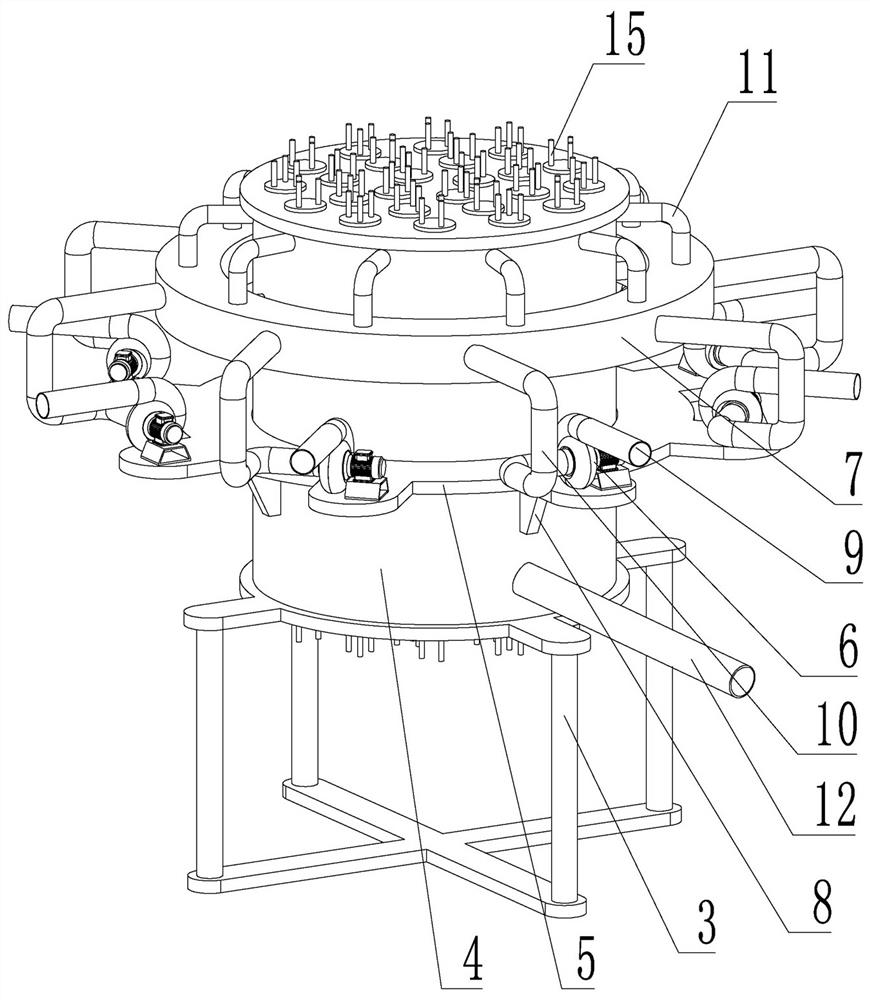

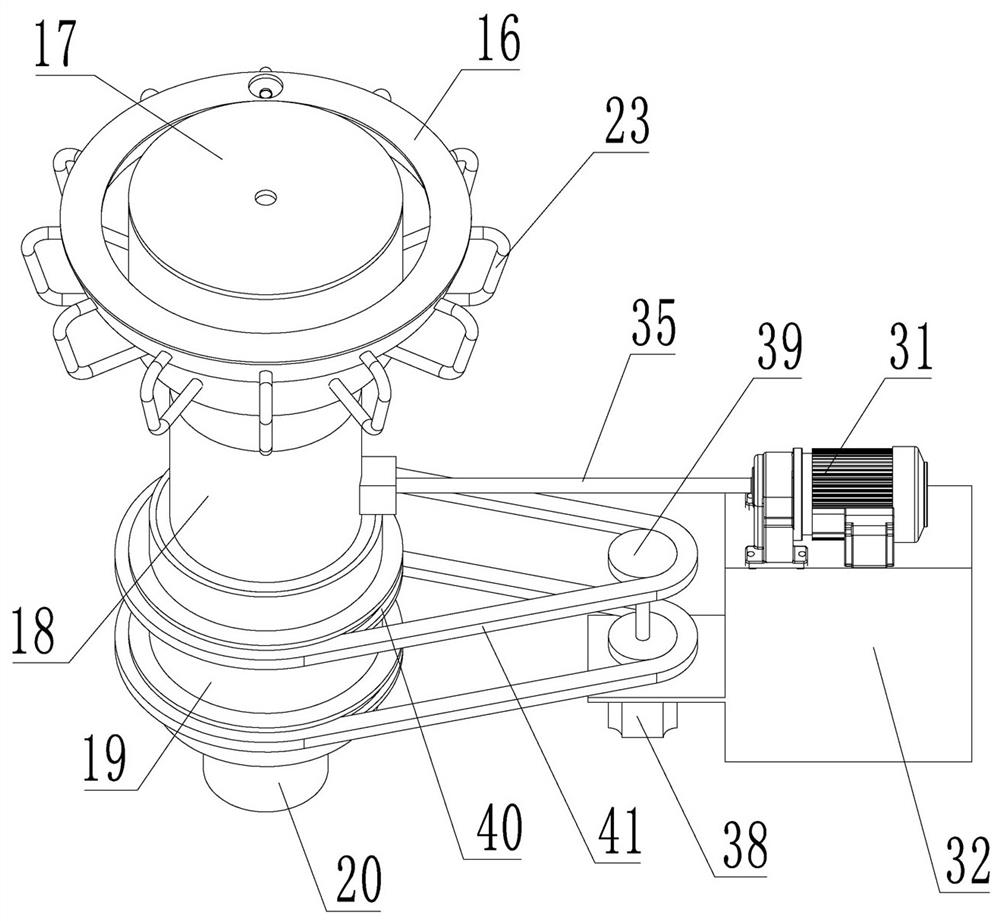

[0032] Such as Figure 1-Figure 9 As shown, the system for increasing the production rate of coalbed methane by mixing hot air proppant includes a high-temperature and high-pressure hot air generating device, a proppant storage tank 1, a proppant delivery pump 2, and a multi-stage mixing device. The air inlet end of the stage mixing device is connected, the discharge end of the proppant storage tank 1 is connected with the feed end of the proppant delivery pump 2, and the discharge end of the proppant delivery pump 2 is connected with the feed end of the multistage mixing device, The mixture discharge end of the multistage mixing device is connected with the upper end of the coal seam well opened in the low coal rank reservoir.

[0033] The high-temperature and high-pressure hot air generating device includes a first bracket 3, a ceramic heating box 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com