Oxygen filling monitoring device

A monitoring device, oxygen technology, applied in container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve problems such as expansion, explosion, oxygen cylinder pressure rise, etc., and achieve a reasonable circuit connection structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

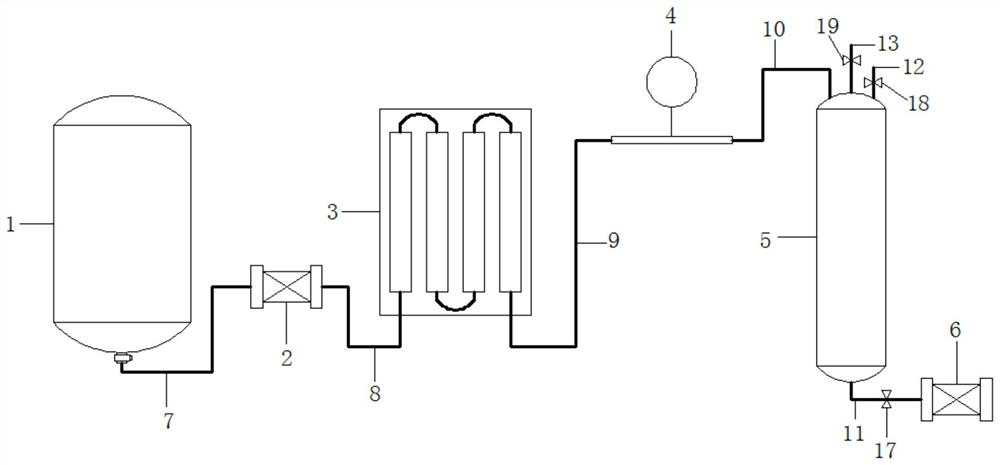

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

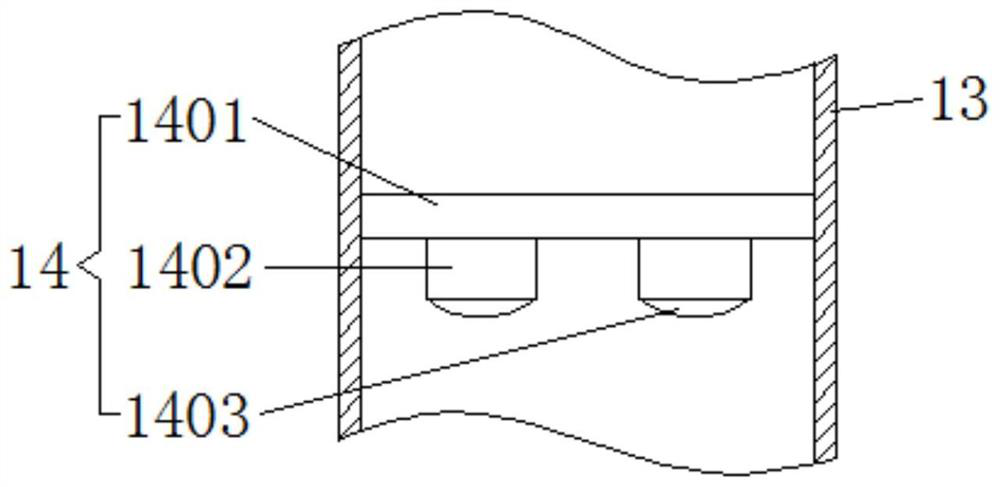

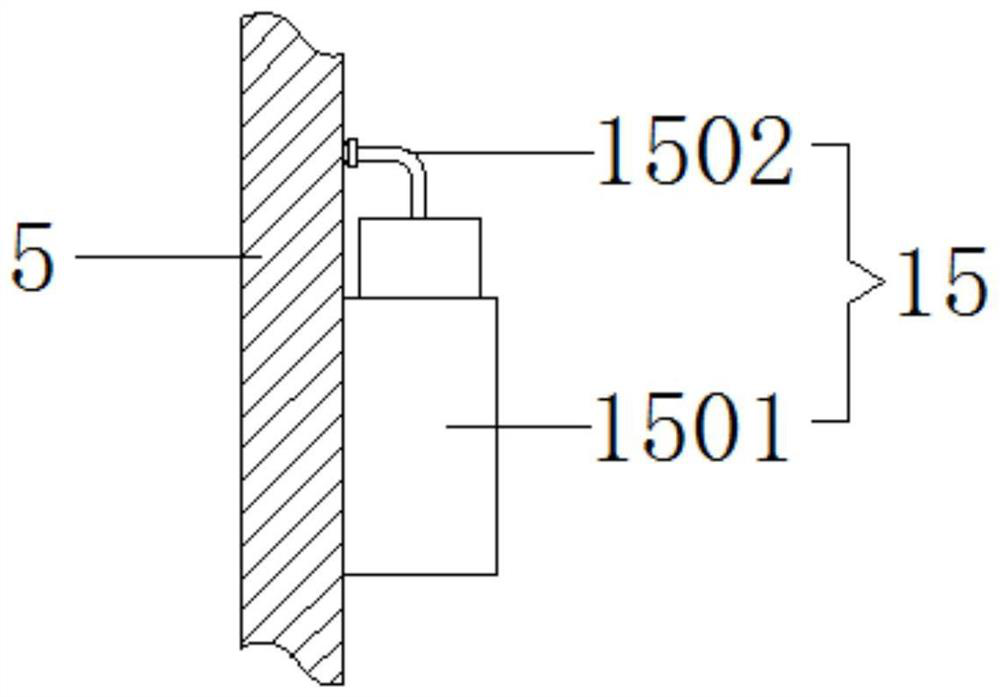

[0033] The invention provides a technical solution: an oxygen filling monitoring device, including a liquid oxygen tank 1, a liquid oxygen pump 2, a vaporizer 3, a bus bar 4, an oxygen cylinder 5 and a vacuum pump 6, and the liquid oxygen tank 1 and the liquid oxygen pump 2 1# pipeline 7 is set between them, 2# pipeline 8 is set between liquid oxygen pump 2 and vaporizer 3, 3# pipeline 9 is set between vaporizer 3 and bus bar 4, and bus bar 4 and oxygen cylinder 5 are set There is a 4# pipeline 10, a 5# pipeline 11 is arranged between the oxygen cylinder 5 and the vacuum pump 6, an emptying pipe 12 and a monitoring pipe 13 are arranged on the oxygen cylinder 5, and an internal detection device 14 is arranged in the inner chamber of the monitoring pipe 13, and the oxygen The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com