Flame-retardant 5G cable

A flame-retardant, 5G technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the adverse effects of cable core heat dissipation, can not meet the 5G conduction and other problems, and achieve the effect of good heat dissipation and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

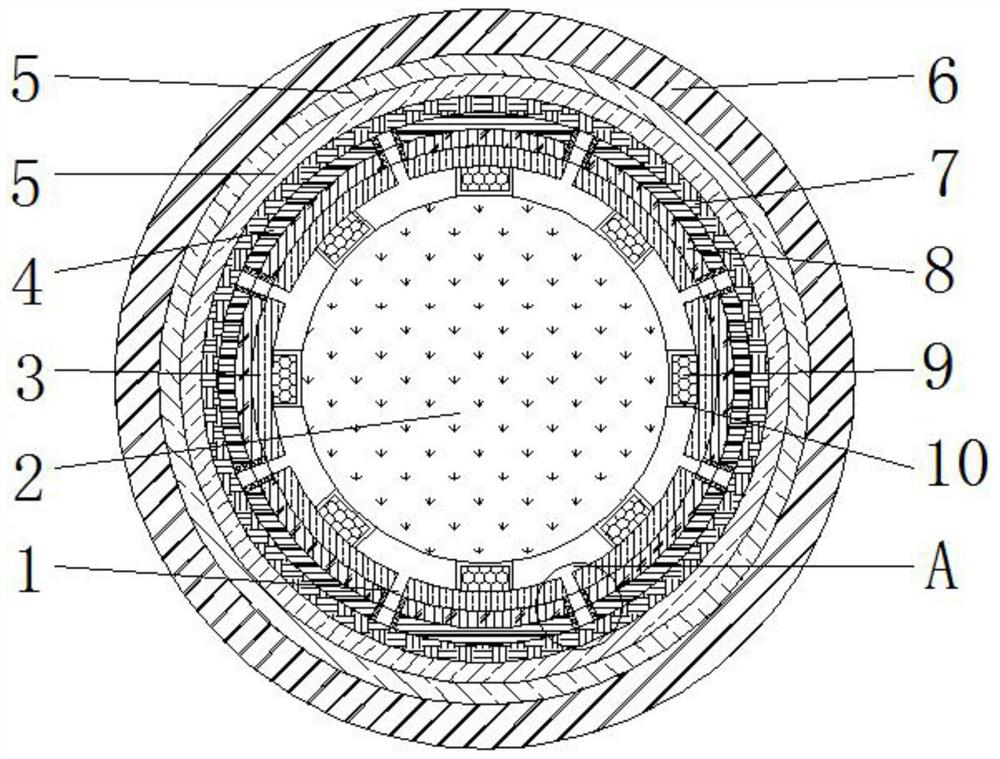

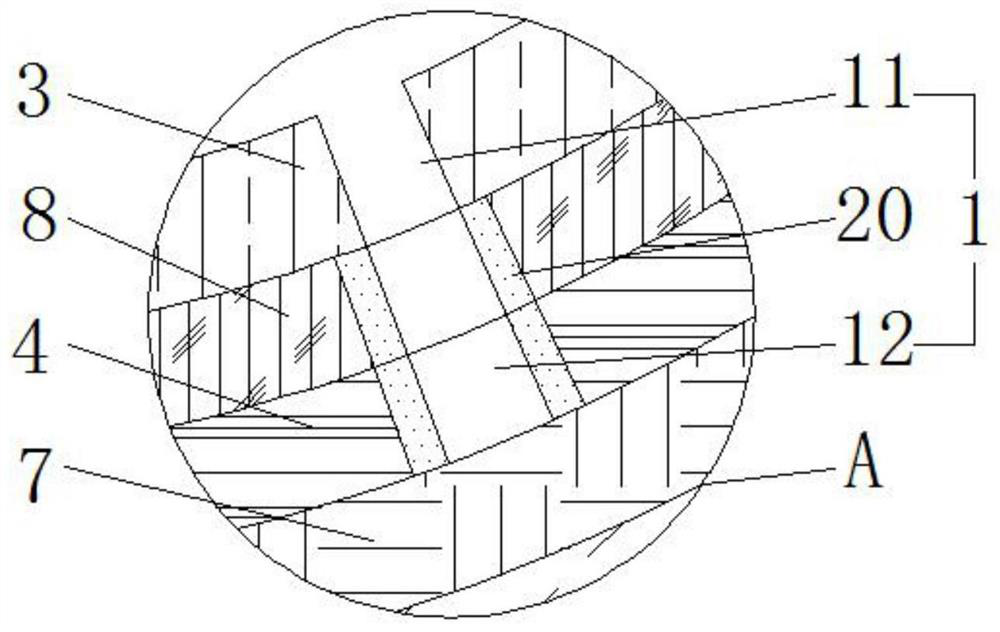

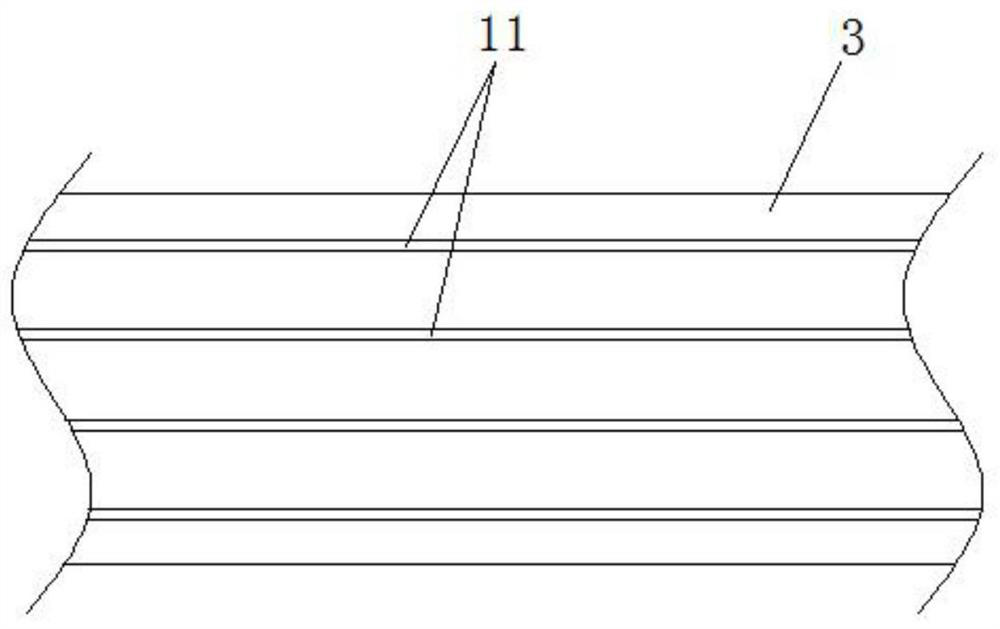

[0031] Such as figure 1 The shown flame-retardant 5G cable includes a cable core 2 and a functional layer wrapped on the outside of the cable core 2 and a sheath layer 6 wrapped on the outside of the functional layer; the functional layer includes an elastic spacer arranged on the outside of the cable core. The thermal layer 3 and the heat-shrinkable layer 4 arranged on the outer side of the elastic heat insulation layer 3, the functional layer is provided with at least two rows of heat dissipation holes 1 at equal intervals along its circumference, and the heat dissipation holes 1 are parallel to the length of the cable In the shape of a crack, the outer side of the cable core 2 is fixed with heat-expandable tires 9 corresponding to the number of rows of heat dissipation holes 1 at equal intervals along its circumference, and each heat-expandable tire 9 is in contact with two adjacent rows of heat dissipation holes 1 The heat-expandable tire 9 is fixed on the cable core 2 by a ...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is:

[0044] In this embodiment, as figure 1 As shown, the outer side of the heat-shrinkable layer 4 is coated with a water-blocking tape layer 7. The thermally expandable microspheres are made of high-temperature resistant foam materials, which will expand when heated, and have a very low heat transfer coefficient, which can meet the design requirements.

[0045] In this embodiment, as figure 1 As shown, two reinforcing layers 5 are provided between the functional layer and the sheath layer 6, and the reinforcing layer 5 is formed by alternately intermittently connecting a reinforcing ring body 51 and an elastic ring body 52, and one of the reinforcing layers The reinforcing ring body 51 of 5 is aligned with the elastic ring body 52 of another reinforcing layer 5. The reinforcement layer 5 formed by alternately and intermittently connecting the reinforcement ring body 51 and the elastic ring body 52 has certain streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com