Granulated feed curing dryer

A pellet feed and dryer technology, applied in feed, food science, application and other directions, can solve the problems of poor work quality and inability to guarantee the degree of drying, and achieve the effect of improving work quality, saving manpower and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

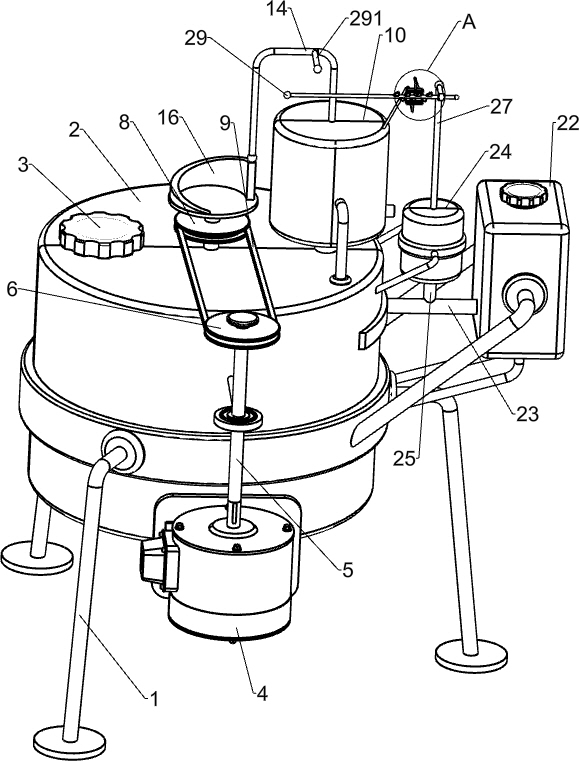

[0021] A pellet feed drying machine, such as Figure 1-5 As shown, it includes a mounting frame 1, a stirring component, an air blowing component and a discharge component. Gas assembly, the bottom of the stirring assembly is provided with a discharge assembly that discharges through rotation.

[0022] When using this equipment to dry pellet feed, the staff pours the pellet feed that needs to be dried into the mixing assembly for stirring, and at the same time, the pellet feed is dried by the air blowing assembly. After completion, the staff opens the discharge assembly Pour out the dried feed for collection.

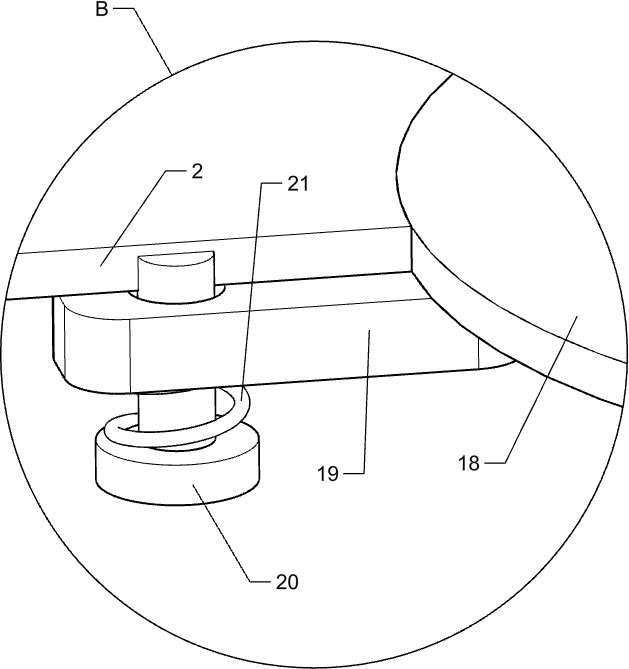

[0023] Such as figure 1 and 2 As shown, the mixing assembly includes a mixing tank 2, a feeding pipe 3, a reduction motor 4, a rotating shaft 5, a first pulley 6, a stirring rod 7, a second pulley 8 and a flat belt 9, and the mounting frame 1 is fixed with a stirring Bucket 2, the feeding pipe 3 is welded on the left side of the top of the mixing bucket 2, the lower...

Embodiment 2

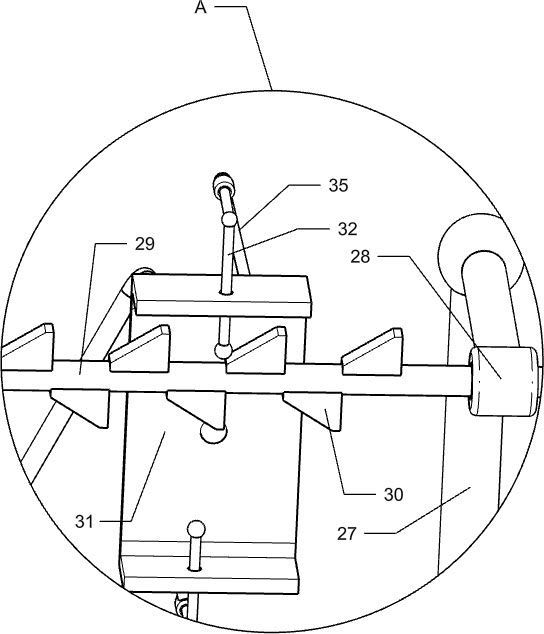

[0030] On the basis of Example 1, such as figure 1 and 2As shown, it also includes a water storage tank 22, a water outlet pipe 23, an arc nozzle 231, a second cylinder body 24, a connecting pipe 25, a second piston 26, a second spring 261 and a push rod 27, and the upper right side of the mounting frame 1 passes through the Bolts are fixed with a water storage tank 22, and the lower left side of the water storage tank 22 is welded with an outlet pipe 23 with a one-way valve. The upper part of the right side is fixedly connected with a second cylinder body 24 by bolts, and a connecting pipe 25 is connected between the bottom of the second cylinder body 24 and the outlet pipe 23. A second piston 26 is slidingly provided in the second cylinder body 24, and the second piston A second spring 261 is connected between the second cylinder 26 and the second cylinder 24, and a push rod 27 is welded on the top of the second piston 26.

[0031] When the pellet feed is stirred and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com