A gravity sedimentation device and method

A precipitation device and gravity type technology, applied in the field of air purification, can solve the problems of expensive dust removal equipment and lack of air purification equipment, and achieve the effects of small footprint, compact structure and high speed reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

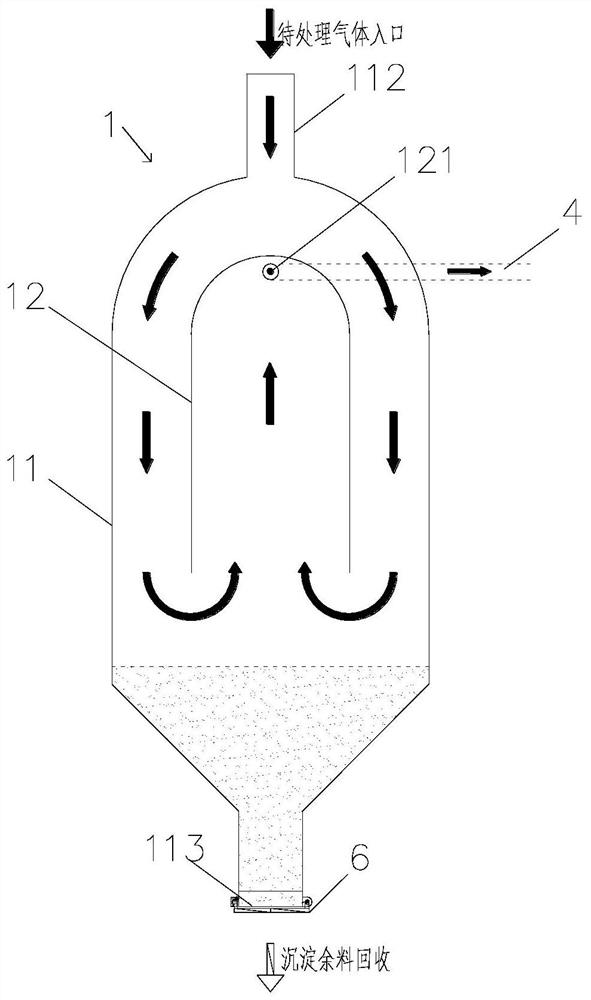

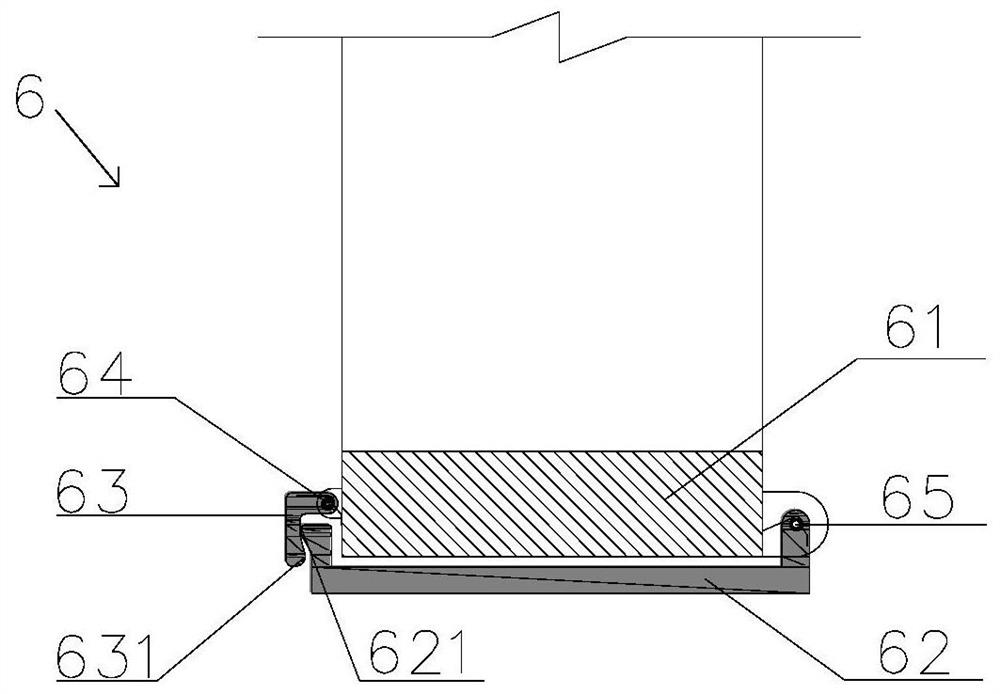

[0034] see Figure 1 to Figure 2 , this embodiment discloses a gravity type sedimentation device 1, including a first airtight container 11 and a first inverted container 12, the top of the first airtight container 11 is provided with a first air inlet 112, the first airtight container 11 The bottom of the container is provided with a precipitation residual material recovery port 113, the first inverted container 12 is an inverted U-shaped structure, the first inverted container 12 is coaxially arranged in the first airtight container 11, and the top of the first inverted container 12 A first air outlet 121 is opened, the bottom opening of the first inverted container 12 is provided, and the flow cross section of the first inverted container 12 is greater than or equal to the flow cross section of the channel between the first airtight container 11 and the first inverted container 12, The dusty gas under pressure, that is, the gas to be treated, enters the first airtight conta...

Embodiment 2

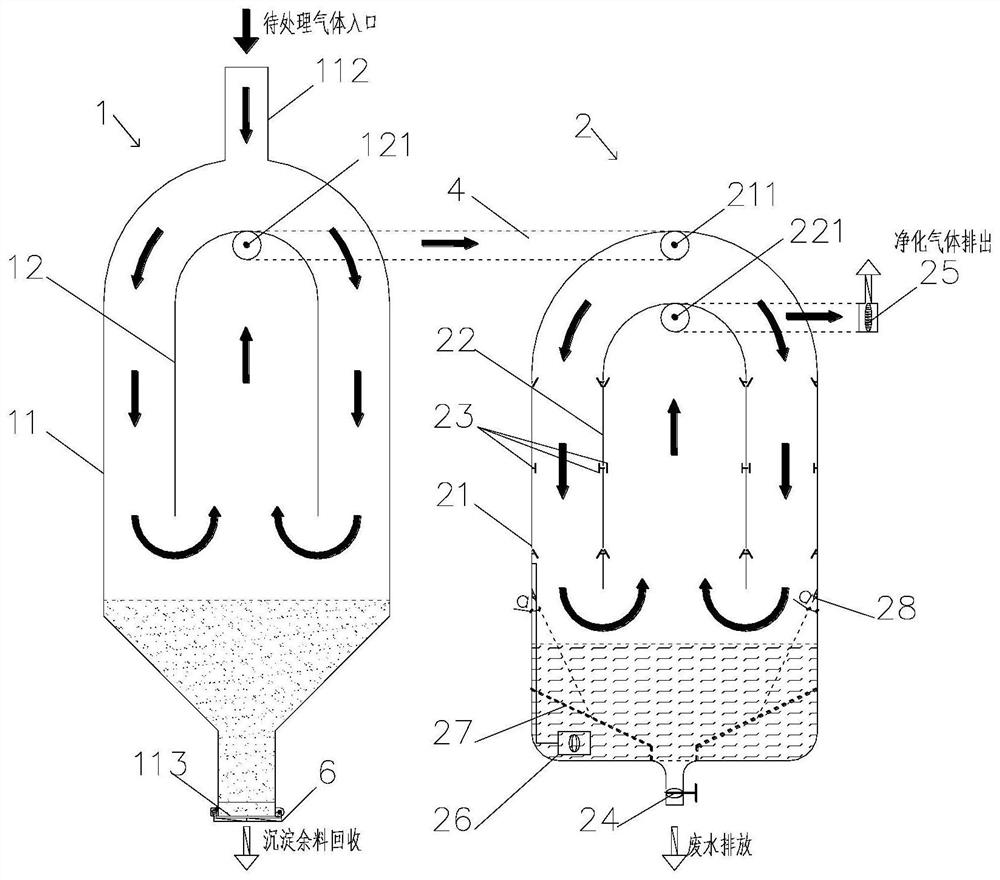

[0041] see Figure 3 to Figure 4 , and please combine Figure 1 to Figure 2 , the pressurized gas purification method of this embodiment has the following differences compared with Embodiment 1:

[0042] The pressurized gas purification method of this embodiment performs spray humidification treatment on the gas treated by the gravity type precipitation device through the spray purification device. The spray purification device 2 includes a second airtight container 21, a second inverted container 22 and several The pipe of the head 23, the top of the second airtight container 21 is provided with a second air inlet 211, the second air inlet 211 is connected to the first air outlet 121 of the spray purification device 1 through the first pipeline 4, and the second air inlet 211 is connected to the first air outlet 121 of the spray purification device 1. The lower part of the second airtight container 21 is used as a water collection tank, the bottom of the water collection tan...

Embodiment 3

[0053] see Figure 5 to Figure 9 , and can be combined with Figure 1 to Figure 4 The difference between the pressurized gas purification method in this embodiment and the second embodiment is that the gas treated by the spray purification device 2 is also subjected to a combined liquid-gas purification treatment through the liquid dust removal mixing chamber 3, so that the solid particles in the gas are further dissolved in the gas. In the liquid, the spray purification device 2 is sealedly connected to the liquid dust removal mixing device 3 through the second pipeline 5, that is to say, the second air outlet 221 does not have an external exhaust valve 25 for discharging purified gas, but The second pipeline 5 is sealed with the liquid dust removal and mixing device 3 , that is to say, the spray purification device 2 is sealed with the liquid dust removal and mixing device 3 through the second pipeline 5 .

[0054] The liquid dust removal and mixing device 3 includes a thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com