A rotary deep drawing die for thin-walled cup-shaped parts

A technology for forming molds and cup-shaped parts, which is applied in the field of rotary deep-drawing forming molds, can solve the problems of large differences in strength in all directions, achieve the effects of reducing forming force, improving plasticity, and realizing grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

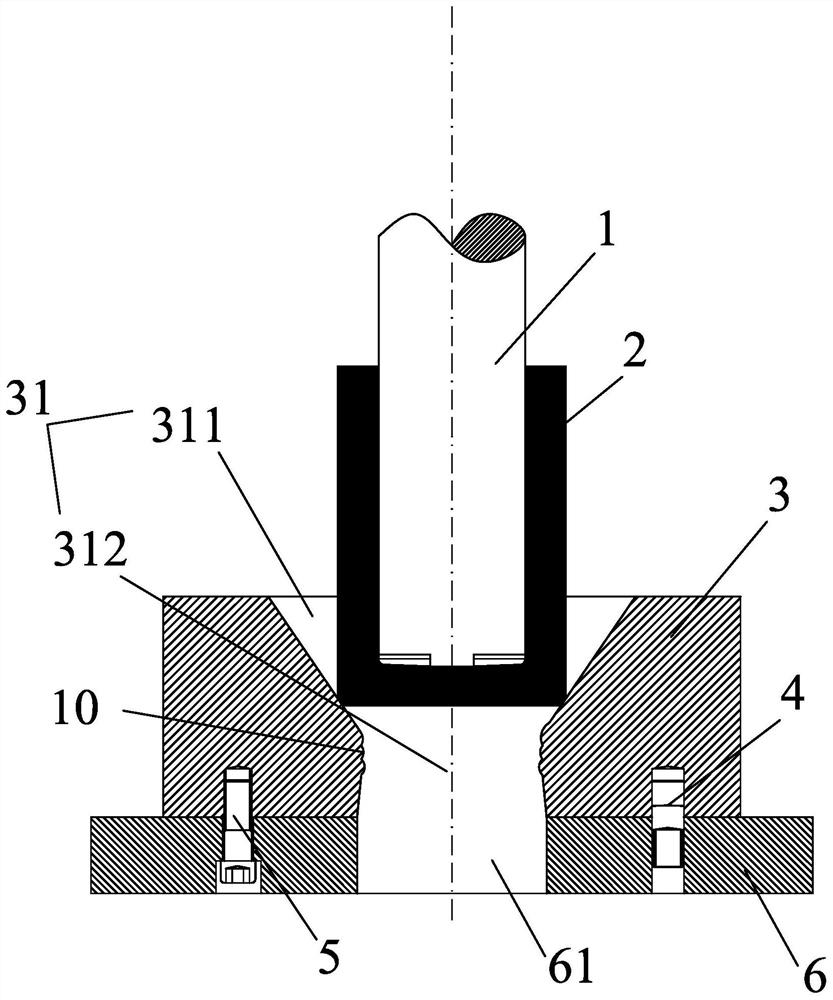

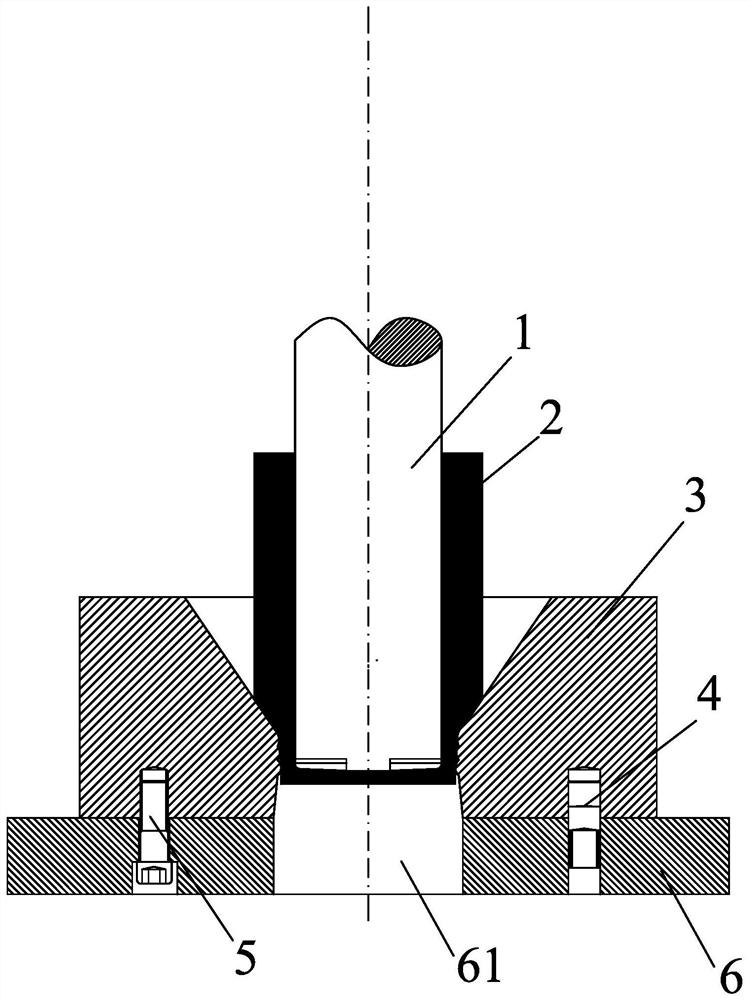

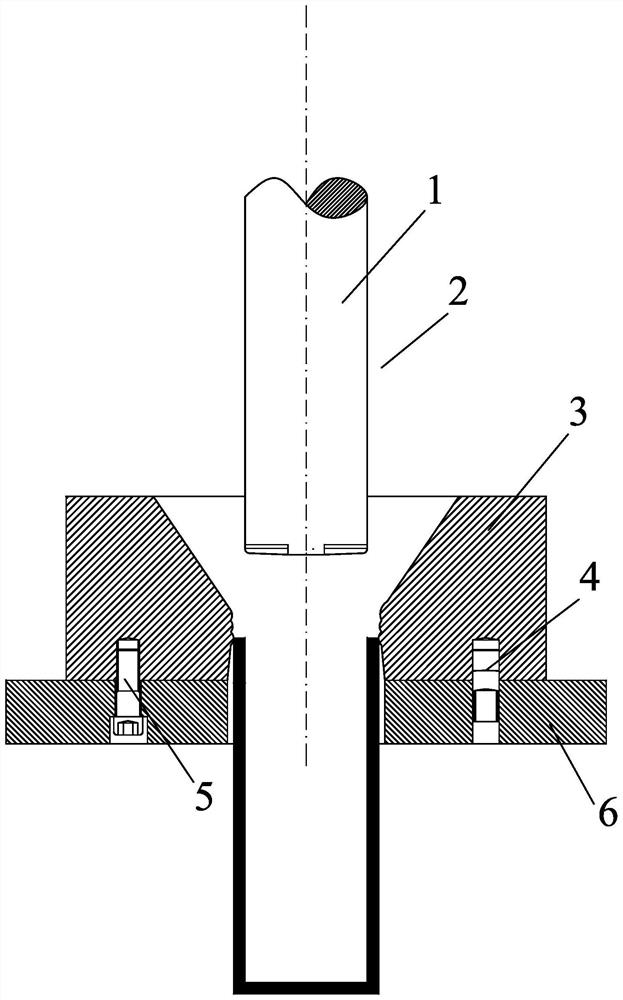

[0029] The invention provides a rotary deep drawing forming mold for a thin-walled cup, such as figure 1 As shown, it includes a punch 1 connected to an upper rotary hydraulic press (not shown in the figure), a forming die 3, a lower template 6 and a lower backing plate (not shown in the figure), and the described punch 1 is coaxially arranged Above the forming die 3, the lower backing plate is arranged between the forming die 3 and the lower template 6 to act as a buffer. The forming die 3 and the lower backing plate pass through the fastener 5 and the positioning pin 4 Connect with the lower template 6.

[0030] The forming die 3 is coaxially provided with a compound cavity 31 for inserting the blank 2. The compound cavity 31 is composed of a V-shaped cavity 311 on the upper part and a rectangular cavity 312 on the lower part. The cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com