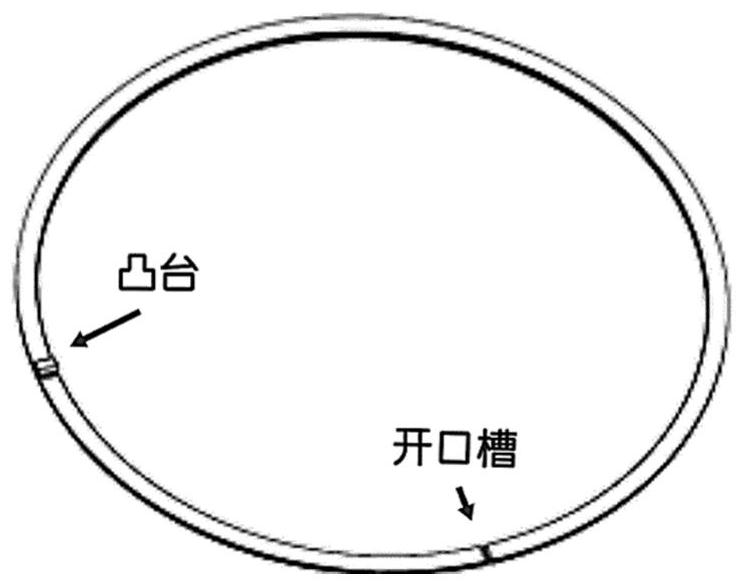

A processing method for a part with a raised ring structure with a boss structure

The technology of a boss structure and a processing method is applied in the processing field of ring-shaped parts with a boss structure, which can solve the problems of difficult processing of ring-shaped parts, and achieve the effects of improving processing efficiency, improving economic benefits, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] The invention provides a processing method for expanding rings with a boss structure, the steps of which are as follows:

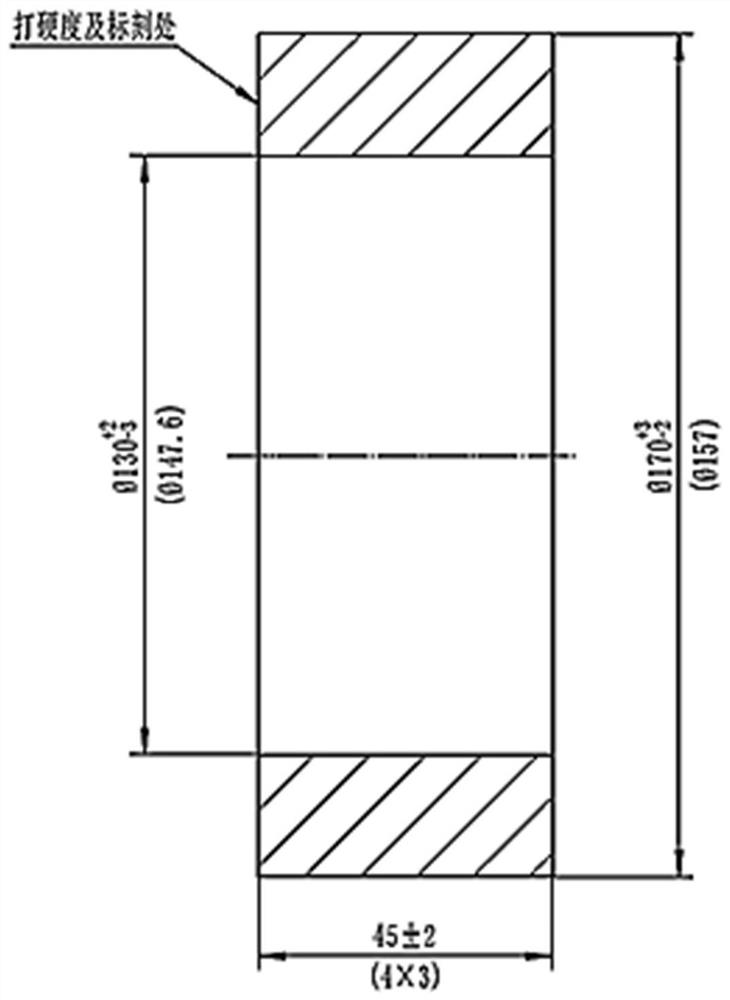

[0042] (1) Making rough forging rings (such as figure 2 );

[0043] (2) The inner and outer surfaces of the parts are machined;

[0044] (3) Stress relief for parts;

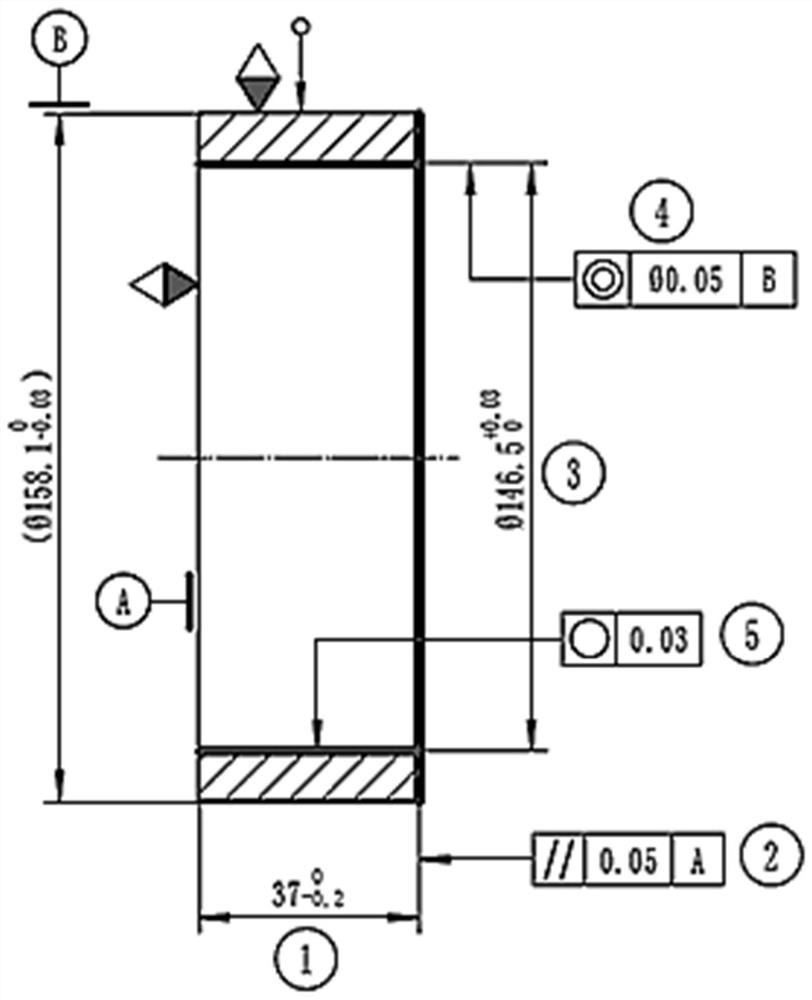

[0045] (4) Semi-finished inner and outer surfaces of parts, such as image 3 , the part is positioned by the end face and the outer circle, the part is clamped by three jaws, the outer circle and the end face are turned by a turning tool, the machining parameters are the spindle speed 400r / min, the cutting depth is 0.5mm, and the feed rate is 0.2mm / r. Guaranteed semi-finishing of parts, bore size and technical conditions.

[0046] (5) Part wire cutting boss (such as Figure 4 );

[0047] When the part wire cuts the boss, cut out the pressure plate for part gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com