Laminating device and method for flexible bionic stepped carton wrapping paper

A lamination device and step-type technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of high cost and no process, etc., achieve convenient operation control, avoid deformation and displacement, and have good lamination effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below with reference to the accompanying drawings and examples:

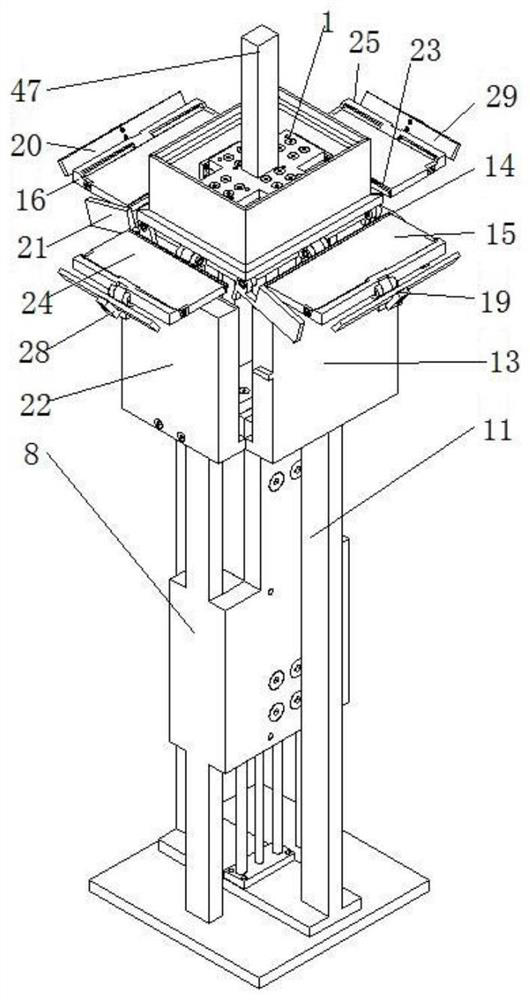

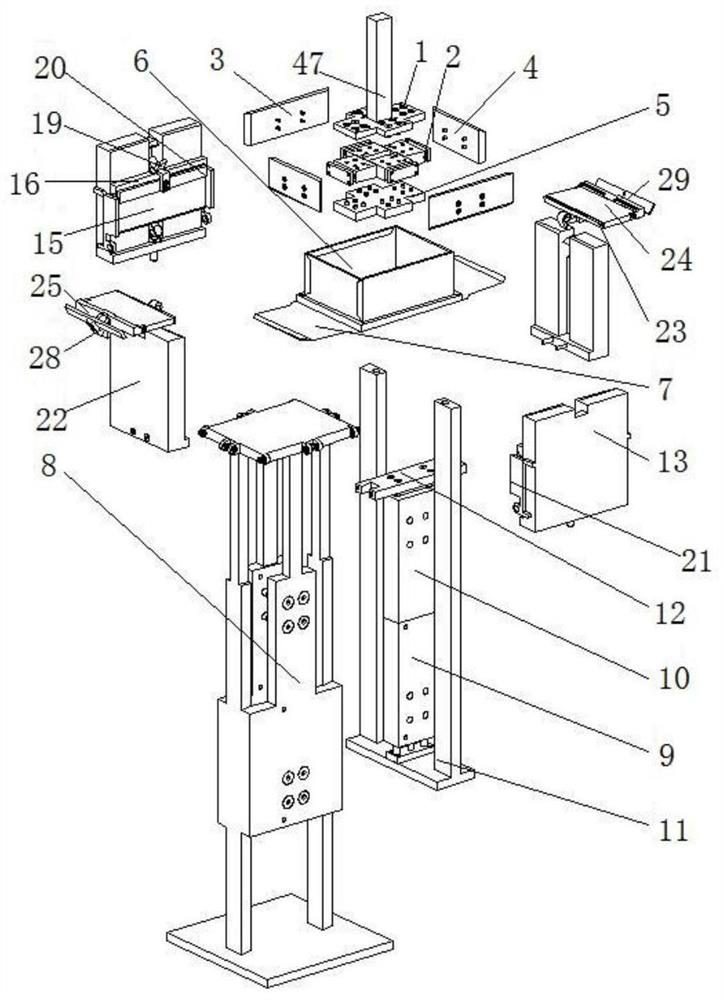

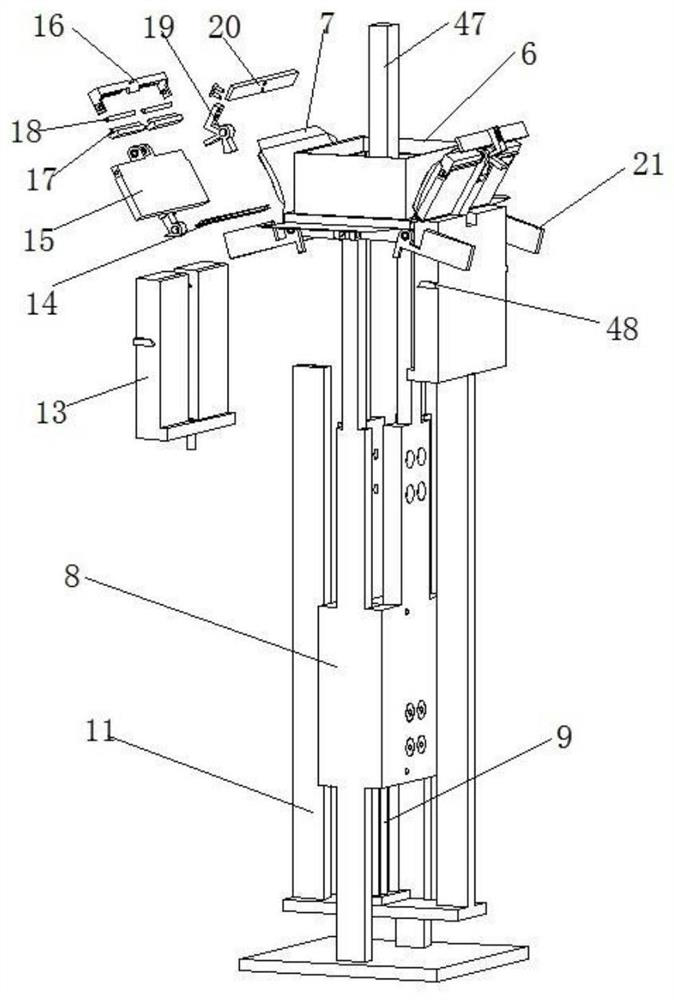

[0048]Such asfigure 1 withFigure 13As shown, a bonding device of a flexible biomimetic clay paper cartridge, including stepped paper cartridges, including auxiliary components, a wide binding bionic sticker mechanism, and a narrow bionic bionic sticker mechanism;

[0049]The auxiliary component includes positioning the cylinder line 47 and the base 8, and the bottom end of the positioning cylinder line 47 is fixedly coupled with four sets of positioning guide cylinders 2, four sets of positioning guide bar cylinders 2, two sets of positioning positioning. The front end of the guide bar of the guide bar cylinder 2 is fixedly mounted with a wide-side positioning plate 3, and the front end of the two sets of opposing positioning guide bar cylinders 2 is fixedly mounted with a narrow-side positioning plate 4, a wide-edge positioning plate 3 and a narrow side positioning. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com