Metering bottle cap

A bottle cap and cap body technology, applied in the field of bottle caps, can solve the problem of inability to quantitatively take bottles of different volumes, etc., and achieve the effects of convenient assembly and fast production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings.

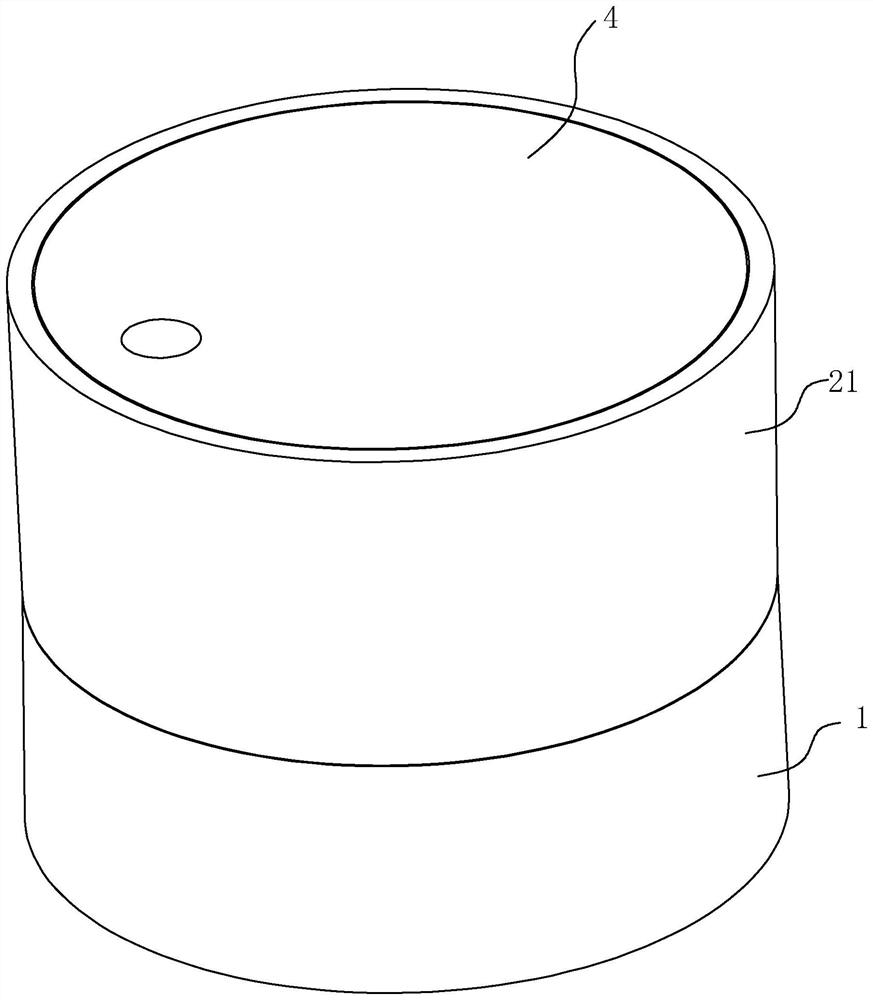

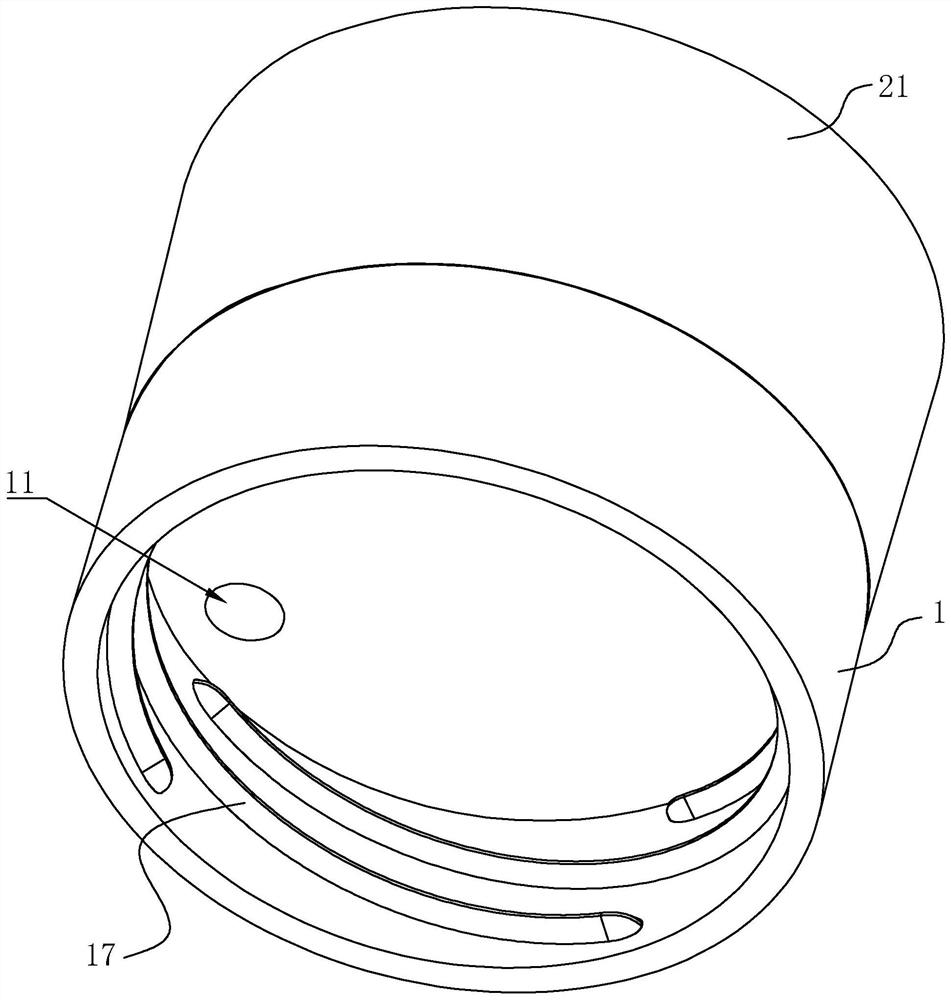

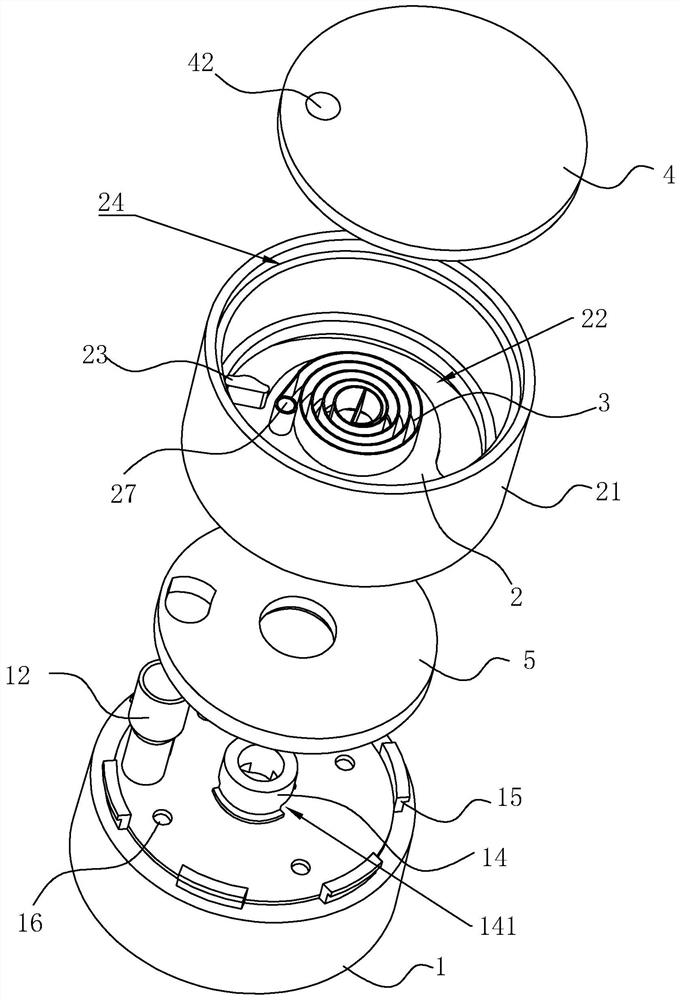

[0037] Such as Figure 1 to Figure 2 As shown, the metering bottle cap disclosed in the present invention includes a cylindrical cap body 1 for sealing the mouth of a conventional bottle body (not shown in the figure). The inner peripheral surface of the cap body 1 is provided with The internal thread 17 of the bottle mouth threaded connection, in other embodiments, the thread can be replaced with various structures or methods that can be connected to the bottle mouth, such as clamping and bonding. Such as Figure 2 to Figure 3 As shown, the upper end of the cover body 1 is blocked, and the blocked end of the cover body 1 is provided with a discharge port 11 communicating with the bottle mouth. A flexible tube 12 is connected to the end of the discharge port 11 away from the bottle mouth, and the discharge port 11 The flexible tube 12 and the central axis of the cover 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com