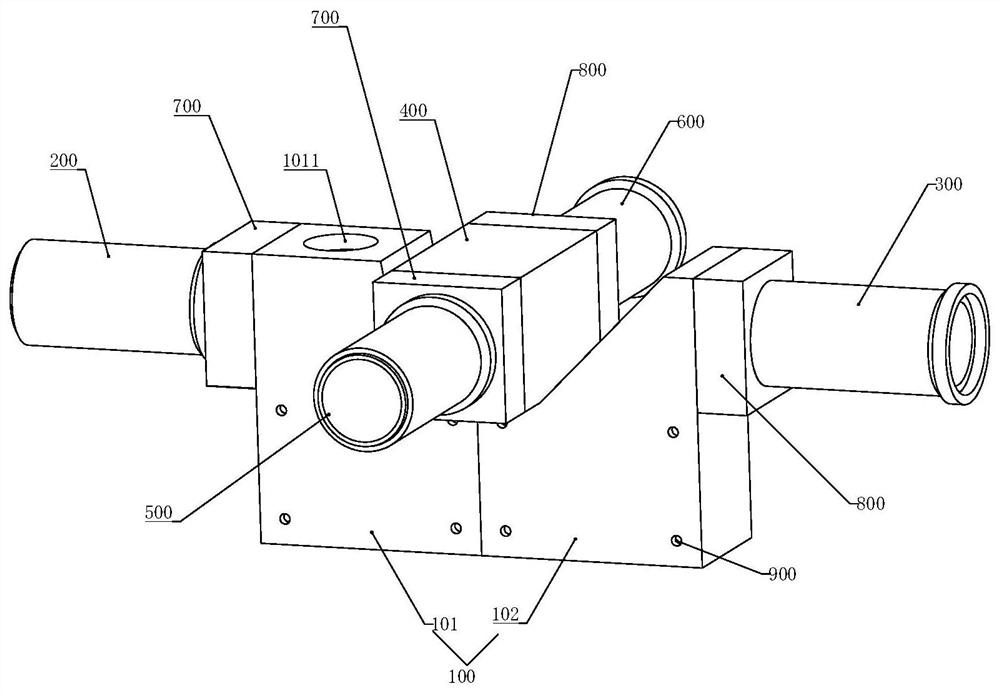

Assembled rainwater and sewage diverging interchange inspection well

A rain and sewage diversion and inspection well technology, which is applied in water supply devices, waterway systems, sewer pipeline systems, etc., can solve the problems of serious sewage sedimentation, difficult construction, and long working cycle, and achieve the improvement of project quality, convenient implementation, and improvement overall image effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

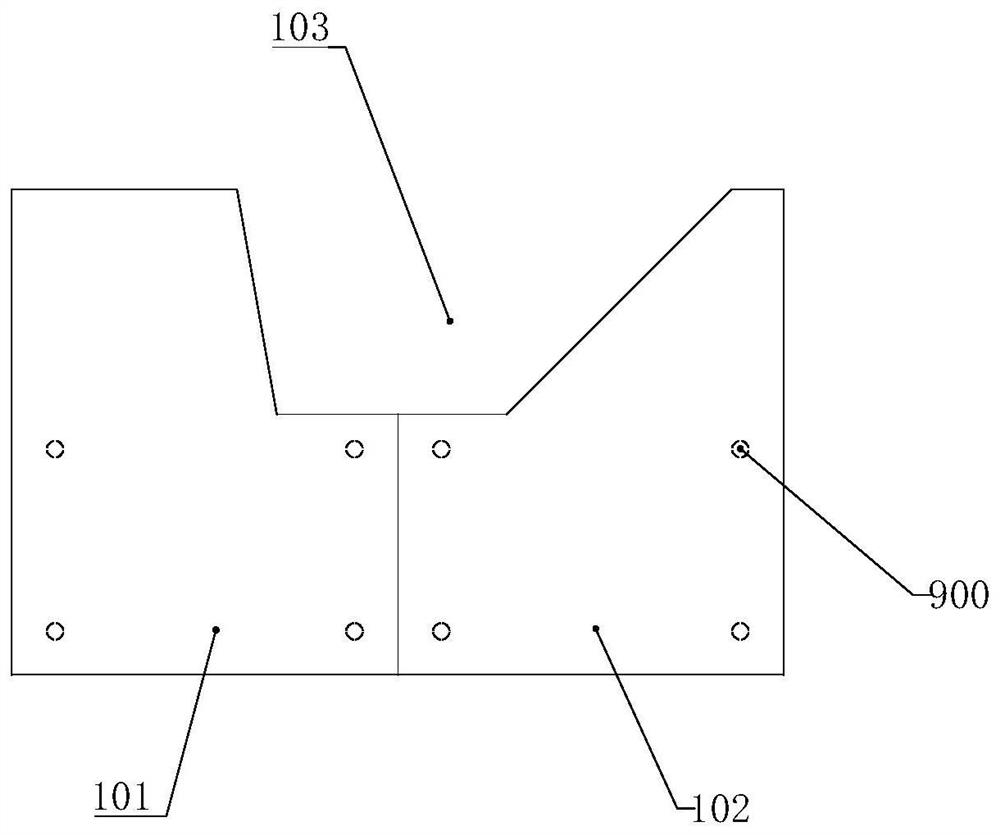

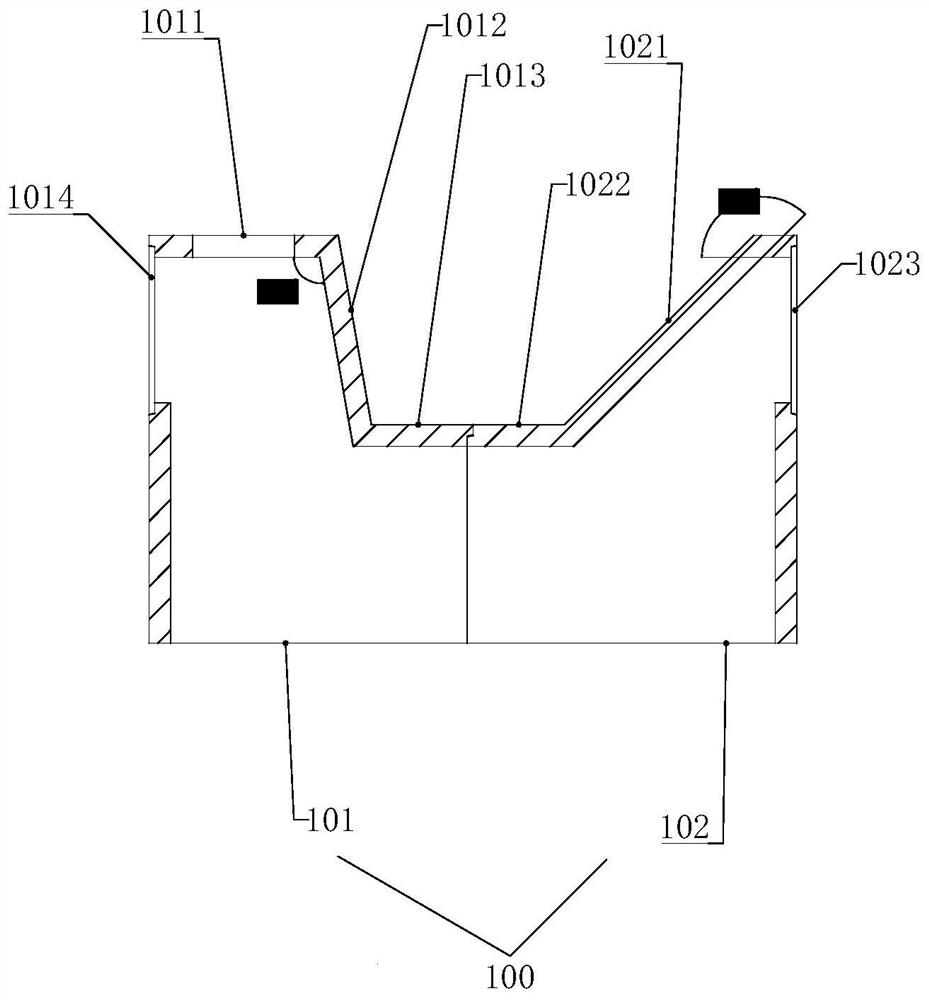

[0035] First, the prefabricated inspection well is transported to the construction site, and the left and right inspection well modules are successively placed in the construction tunnel by using hoisting equipment. Since the left end surface of the inspection well module 101 is provided with a protruding plug connector ( not shown in the figure), the left end surface of the right inspection well module 102 is provided with a recessed joint (not shown in the figure), so the left inspection well module 101 and the right inspection well module 102 can be plugged in quickly and conveniently connected together. In order to ensure a good sealing performance after the left inspection well module 101 and the right inspection well module 102 are connected, before the left inspection well module 101 and the right inspection well module 102 are connected, it is necessary to paste a circle around the joint of the right inspection well module 102 The water-swelling sealing strip, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com