One-time forming and installation method for super high-rise standard floor electromechanical pipelines

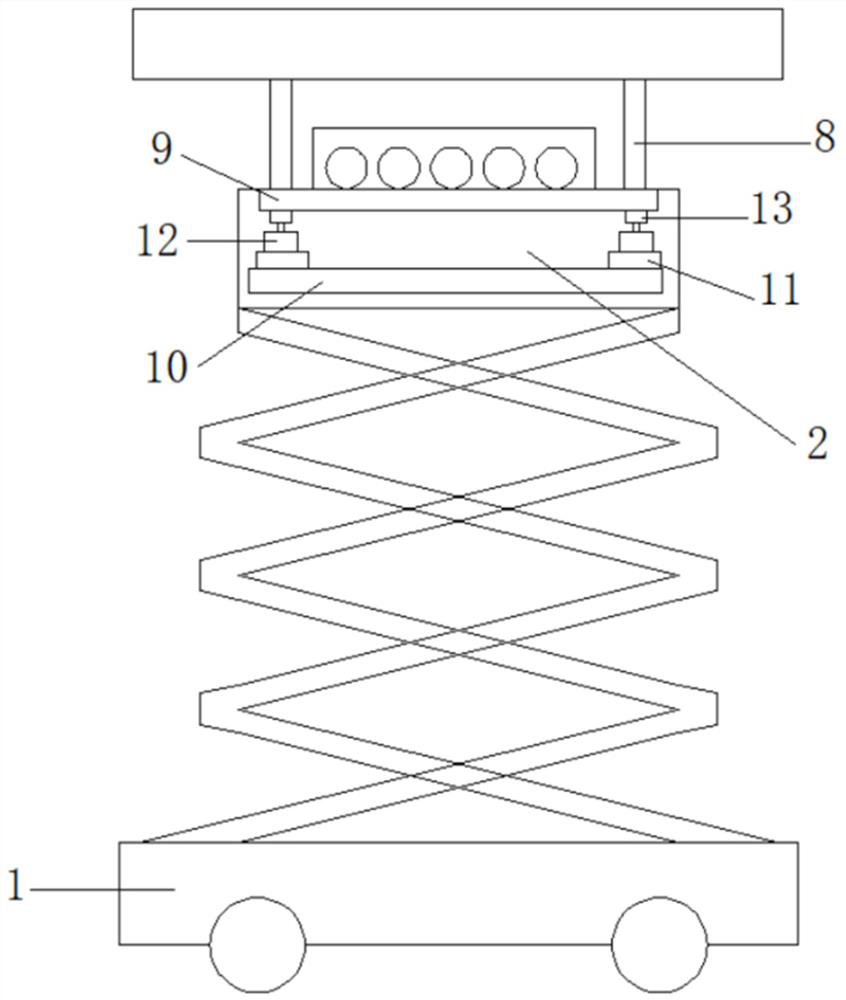

An installation method and standard layer technology, which are applied in the field of one-time forming and installation of electromechanical pipes of super high-rise standard floors, can solve problems such as affecting the progress of electromechanical installation projects, insecurity, etc., and achieve the effects of saving manpower, convenient manual movement, and convenient connection and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Before carrying out electromechanical installation, the following items should be noted:

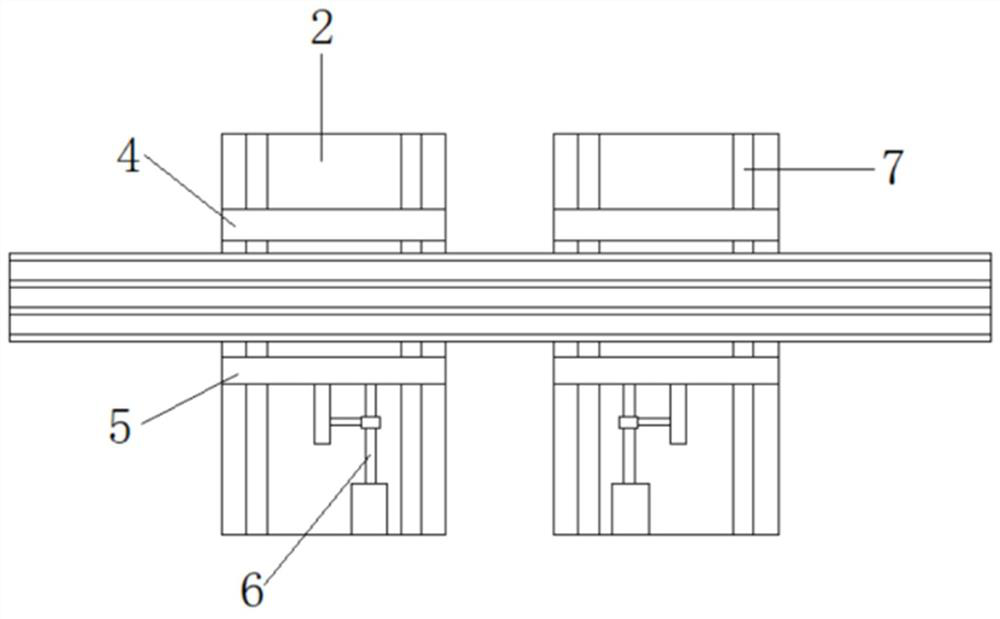

[0048] According to on-site installation conditions, transportation conditions, material size parameters and prefabricated processing and production conditions, combined with the corresponding construction design specifications: "Building Water Supply and Drainage Design Specifications", "Civil Building Heating Ventilation and Air Conditioning Design Specifications", "Civil Building Electrical Design Specifications" ", "Code for Seismic Design of Building Mechanical and Electrical Engineering" and so on to decompose prefabricated components.

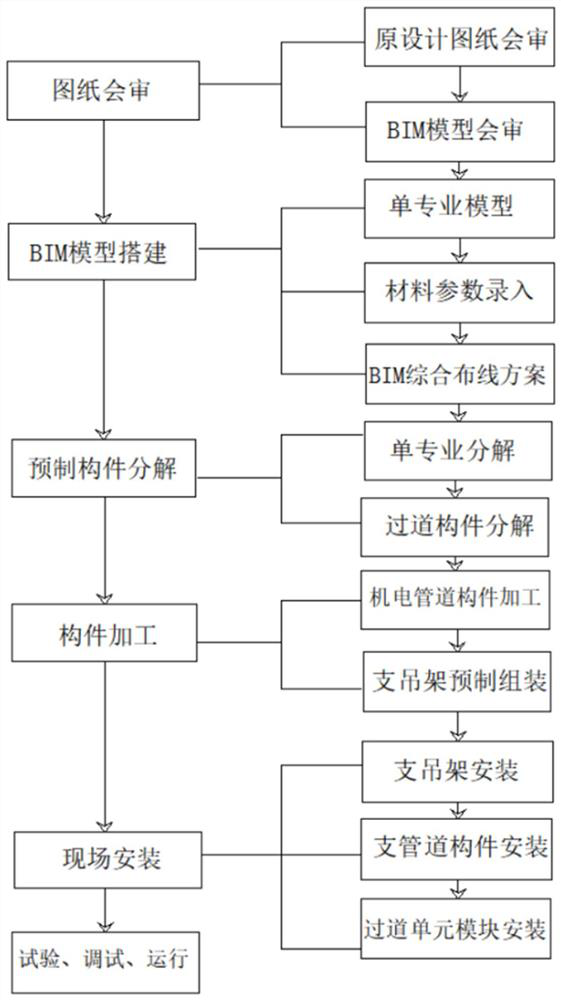

[0049] According to the joint review of drawings, owner's requirements, on-site installation conditions, etc., BIM technology is used to coordinate various disciplines to conduct full-professional collision inspection, space clear height analysis, comprehensive design of electromechanical pipelines, combined with electromechanical pipelines, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap