Neutron generator neutron yield control system and method

A technology of a neutron generator and a control method, which is applied in control/regulation systems, instruments, DC voltage accelerators, etc., can solve the problems of fluctuation of neutron yield, reduction of capacitance value of silicon stack capacitor, and reduction of neutron yield, etc. Achieve the effect of stable neutron yield output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

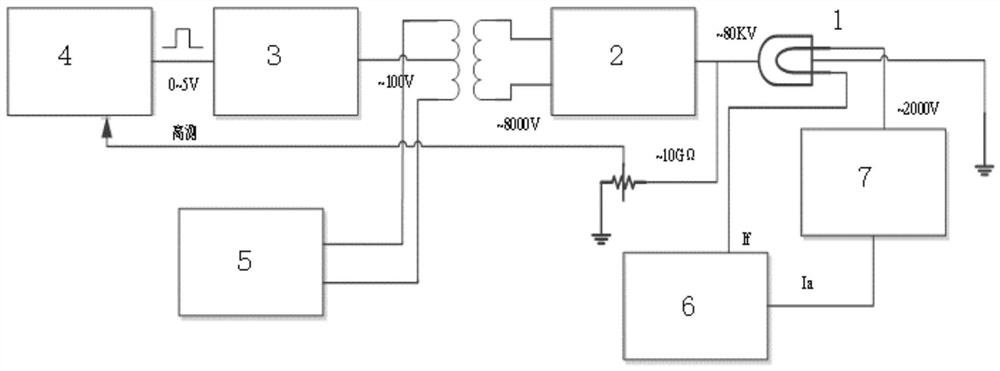

[0027] Such as figure 1 As shown, the neutron yield control system of the neutron generator according to the present invention includes a neutron tube 1, a voltage doubling nipple 2, a linear power supply module 3, a generator high voltage control circuit 4, a generator high voltage drive circuit 5, Ion source circuit 6, anode high voltage module 7 and step-up transformer.

[0028] A voltage-resistant high-resistance resistor of about 10GΩ is installed in the voltage doubler joint 2. The output terminal of the generator control circuit 4DA is connected to the control input terminal of the linear power supply module 3, and the output terminal of the linear power supply module 3 is connected to the center tap input of the step-up transformer. The output terminals of the high-voltage drive circuit 5PWM wave are respectively connected to the input terminals of the step-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com