Solid electrolytic capacitor

一种固体电解、电容器的技术,应用在固体电解电容器、电解电容器、电容器等方向,能够解决制造工艺复杂化、电容有效体积变小、金属箔不具有电容器功能等问题,达到可靠性优异、容易廉价制作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

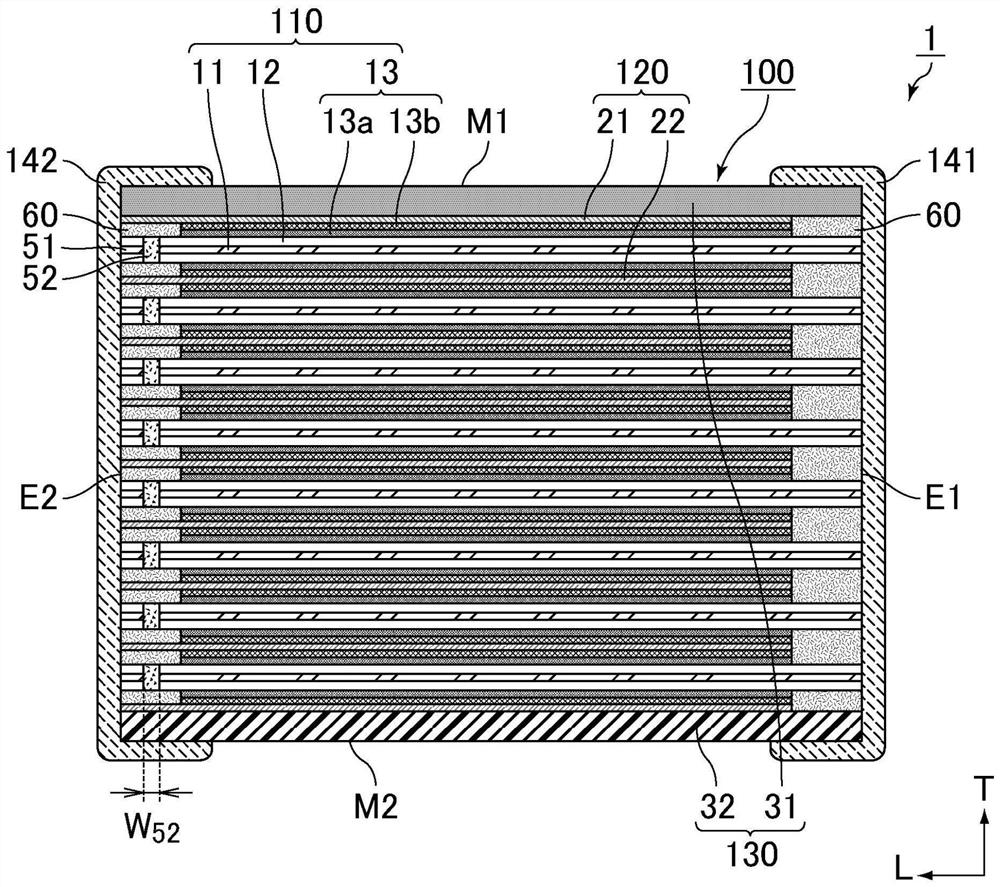

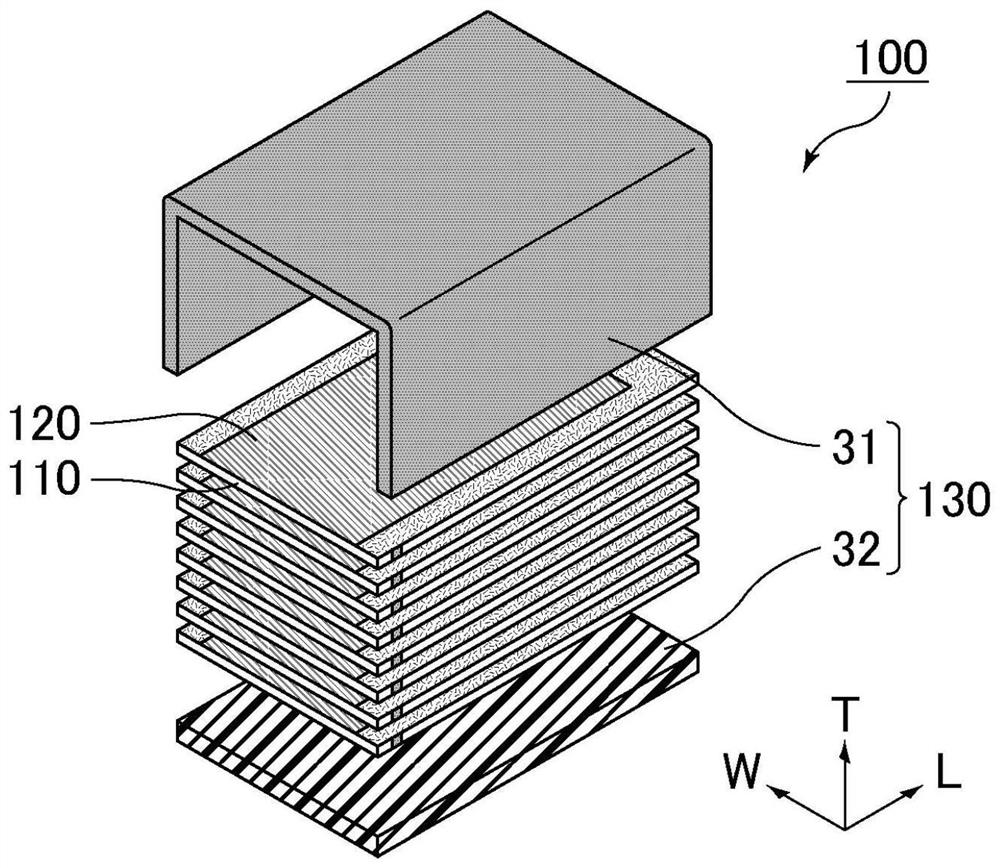

[0078] In the solid electrolytic capacitor according to the first embodiment of the present invention, the metal foil exposed on the second end surface of the element laminate is provided in a space where there is no capacitor element between the first cathode extraction layer and the second cathode extraction layer. . The above-mentioned metal foil is cut from the anode foil through a slit, and is completely insulated from the anode foil.

[0079] In the solid electrolytic capacitor according to the first embodiment of the present invention, the metal foil cut off from the anode foil is directly used as a support portion of the cathode lead-out layer. Thereby, no difference in the coefficient of linear expansion occurs, and structural deformation, generation of cracks, and the like can be suppressed when heat is applied to the solid electrolytic capacitor.

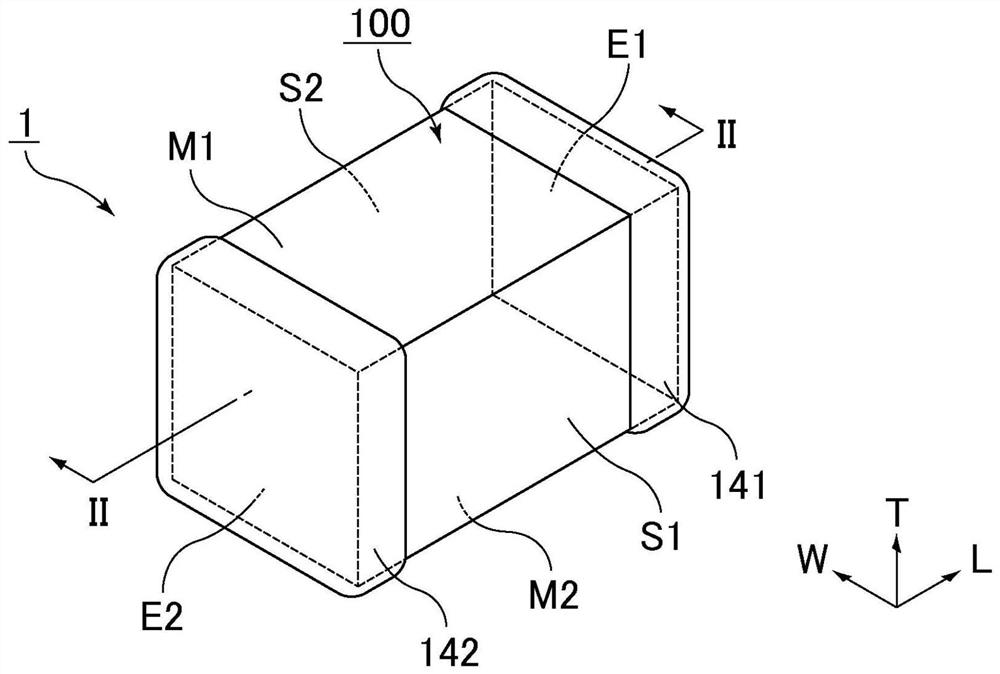

[0080] figure 1 It is a perspective view schematically showing an example of the solid electrolytic capacitor accordi...

no. 2 approach

[0130] In the solid electrolytic capacitor according to the second embodiment of the present invention, an insulating layer is provided to fill the space without the capacitor element between the first cathode extraction layer and the second cathode extraction layer.

[0131] In the solid electrolytic capacitor according to the second embodiment of the present invention, the insulating layer may be made of a different insulating material from the resin molded body, or may be made of the same insulating material as the resin molded body.

[0132] When the insulating layer is made of an insulating material different from the resin molded body, by selecting the insulating material constituting the insulating layer, the insulating layer can be provided with functions for improving reliability, such as a function of low moisture permeability, a stress Mitigation capabilities, etc.

[0133] On the other hand, when the insulating layer is made of the same insulating material as the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com