Raw material mixing device for health-care product production

A technology for mixing devices and health products, which is applied in the field of raw material mixing devices for health products production, and can solve problems such as poor mixing effect, small operating range of the stirring rod, and limited blanking speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

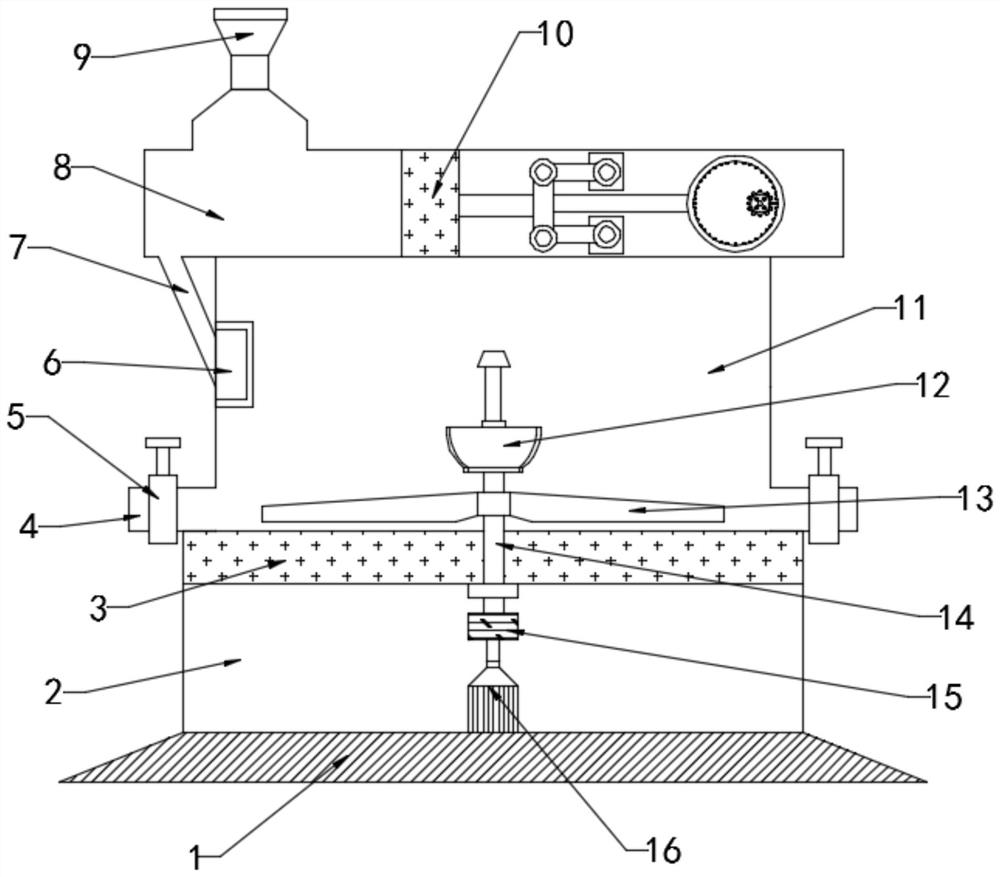

[0025] see figure 1 , in Embodiment 1 of the present invention, a raw material mixing device for production of health care products, which includes: a device body, which is divided into a temporary storage box 8, a mixing chamber 11, and a load-bearing box 2 from top to bottom. The upper end of the temporary storage box 8 is connected to the feed hopper 9, and a feeding assembly 10 is fixed inside the temporary storage box 8. The lower end of the temporary storage box 8 is connected to the mixing chamber 11 through the feeding pipe 7, and the mixing chamber 11 is left The filter frame 6 is installed and fixed on the side inner wall, and the lower end of the feed pipe 7 extends to the filter frame 6; the inside of the mixing chamber 11 is provided with a stirring assembly 12, and the stirring assembly 12 is driven by a driving assembly, and the left and right sides of the lower end of the mixing chamber 11 Connect the discharge pipe 4, the discharge pipe 4 is fixed with a disch...

Embodiment 2

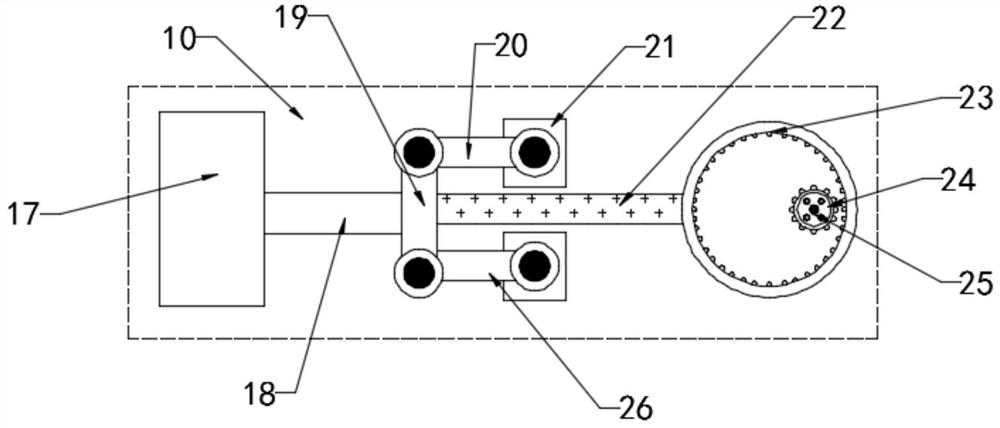

[0029] see figure 2 Further, the feed assembly 10 includes a piston 17, a crank 19, a movable rod 22, a large toothed plate 23 and a driving toothed plate 24, the piston 17 is movably installed inside the temporary storage box 8, and one end of the piston 17 is connected with the push rod 18 The crank 19 is connected, and the upper and lower ends of the crank 19 are hinged and movable respectively with one end of the first rotating handle 20 and one end of the second rotating handle 26 through pin shafts, and the other end of the first rotating handle 20 and the other end of the second rotating handle 26 are all movable installed on the On the fixed block 21; the middle of the crank 19 is connected with the large toothed plate 23 through the movable rod 22, the inner wall of the large toothed plate 23 is engaged with the driving toothed plate 24, and the driving shaft 25 is installed in the middle of the driving toothed plate 24;

[0030] Start the drive shaft 25, the drive s...

Embodiment 3

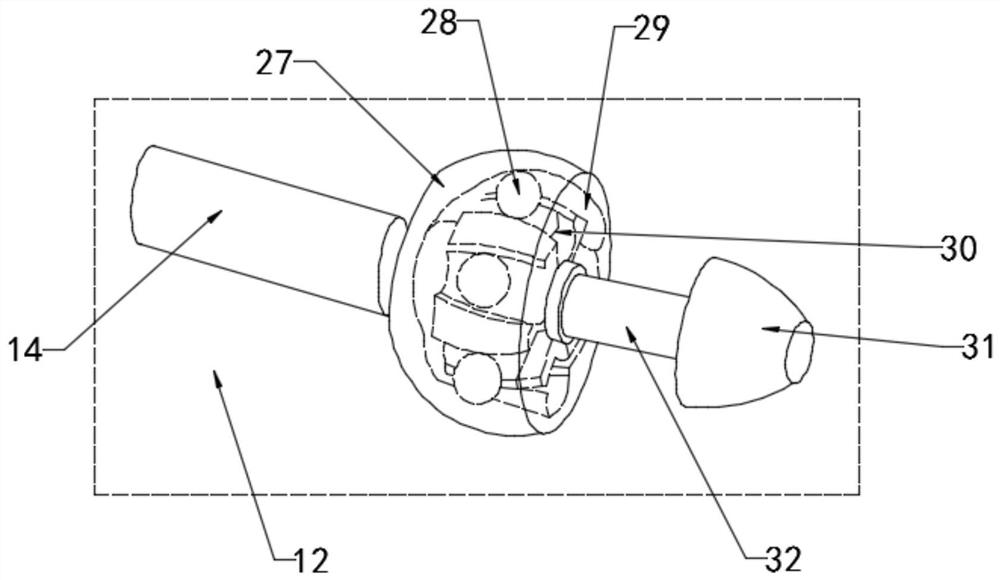

[0035] see image 3 with Figure 4 , the stirring assembly 12 includes a connection end 27, a movable end, a stirring rod 32 and a stirring end 31, one end of the connection end 27 is connected and fixed to the rotating shaft 14, and the movable end is movably installed inside the connection end 27, and the movable end The other end of the head is provided with a stirring rod 32, and one end of the stirring rod 32 is fixed with a stirring end 31;

[0036] Specifically, a movable groove 29 is provided inside the connecting terminal 27, and the movable terminal is movably installed in the movable groove 29 provided inside the connecting terminal 27;

[0037] Furthermore, a rolling rail 30 is provided on the edge of the movable end, and a ball 28 is rollingly installed inside the rolling rail 30, and the rolling ball 28 installed inside the rolling rail 30 is in surface contact with the movable groove 29 provided inside the connecting end 27;

[0038] When the rotating shaft 14 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com