Gluing equipment of motor stator of urban rail and standard traction motor and a gluing method thereof

A technology for traction motors and motor stators, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of unfavorable consequences of traction motor quality, miscoating and missing coatings, complicated gluing steps, etc., and achieve gluing and testing The process is neat and orderly, ensuring the effect of gluing, ensuring zero mistakes and gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

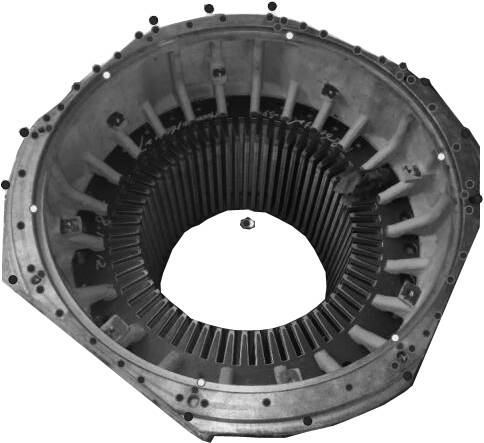

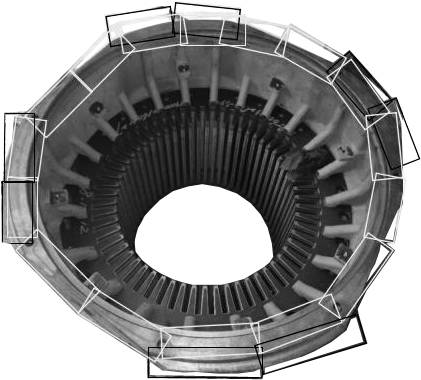

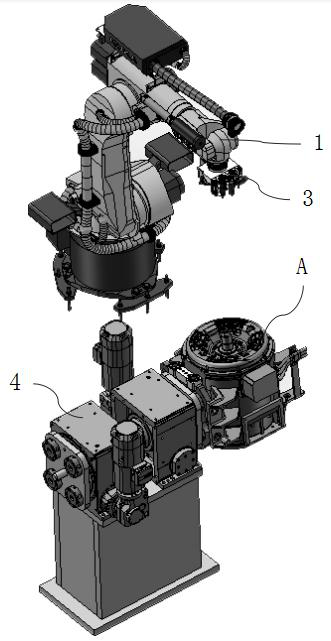

[0043] Such as figure 1 , figure 2 and image 3As shown, a kind of gluing equipment for the motor stator of urban rail and standard motion traction motor includes a first station and a second station. The first station applies glue to the stator end face, and the second station applies glue to the non-drive end The joint seam on the side of the transmission end, the bolt on the transmission end and the joint seam on the side of the transmission end are glued; wherein, the first station includes the first six-axis manipulator 1, the gluing device 2 installed at the end of the first six-axis manipulator, and is used for overturning traction. The positioner 4 for the motor A to realize the gluing operation at both ends. The gluing device 3 includes two or three glue supply mechanisms 31 (some types of motors only need to apply two kinds of glue), and the glue supply mechanisms include glue supply mechanisms. The head 311 and the slide cylinder 312 that control the movement of ...

Embodiment 2

[0055] This embodiment provides a method for gluing using the urban rail and standard traction motor stator gluing equipment of Embodiment 1, including the following steps:

[0056] S1. Glue coating guide on stator end face (all three kinds of glue are applied):

[0057] S11. Establish the tool coordinates of LOCTITE243 thread adhesive, LOCTITE518 metal anaerobic adhesive, SHC-100 grease supply rubber head and the tool coordinates of the midpoint of the laser line of the 3D line-scan laser camera with the same reference point, and use the two stator end faces of the same diameter The direction of the screw hole is the X axis to establish the workpiece coordinates;

[0058] S12. The 3D line-scanning laser camera scans a distance slightly larger than the diameter of the stator along the X-axis direction, and processes the scanned point cloud image through the computer control system to determine the center of the stator processing surface and the radius of the circle where the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com