Guardrail climbing ladder generating device

A technology for generating equipment and climbing ladders, applied in the field of manufacturing, can solve the problems of time-consuming and laborious, lack of automatic feeding, and inaccurate marking methods, so as to reduce risks, save feeding time, and save positioning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

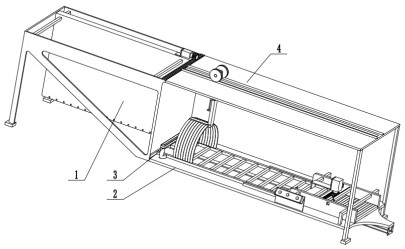

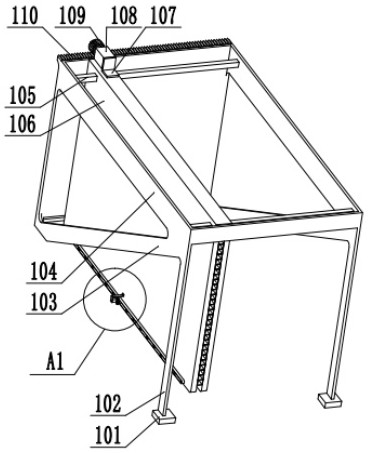

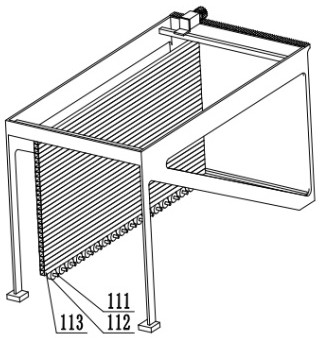

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9The guardrail ladder generation equipment shown includes a long ladder feeding mechanism 1, a handrail feeding mechanism 2, a clamping mechanism 3, and a fence feeding mechanism 4. The long ladder feeding mechanism 1 is fixedly installed on the ground and has a built-in storage Mechanism, driven by the motor, the long ladder can be sent to the position to be welded according to the specified size, and the armrest feeding mechanism 2 is fixedly installed on the ground, with a built-in storage mechanism, driven by the motor, the handrail can be sent to the position to be welded according to the specified size, and at the same time It also has the function of positioning and clamping. The clamping mechanism 3 is fixedly installed on the handrail feeding mechanism 2, and its effect is to clamp the parts to be welded before welding. The fence feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com