Wall grooving cutting device for architectural engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

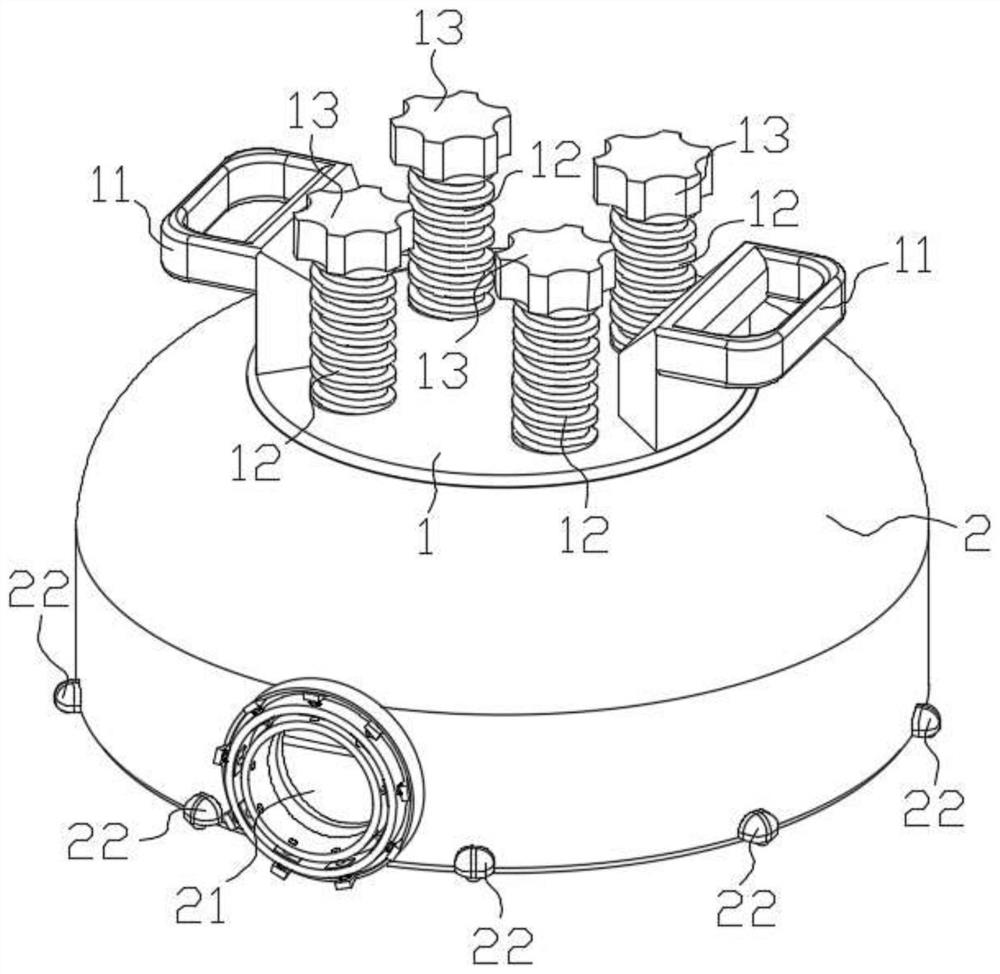

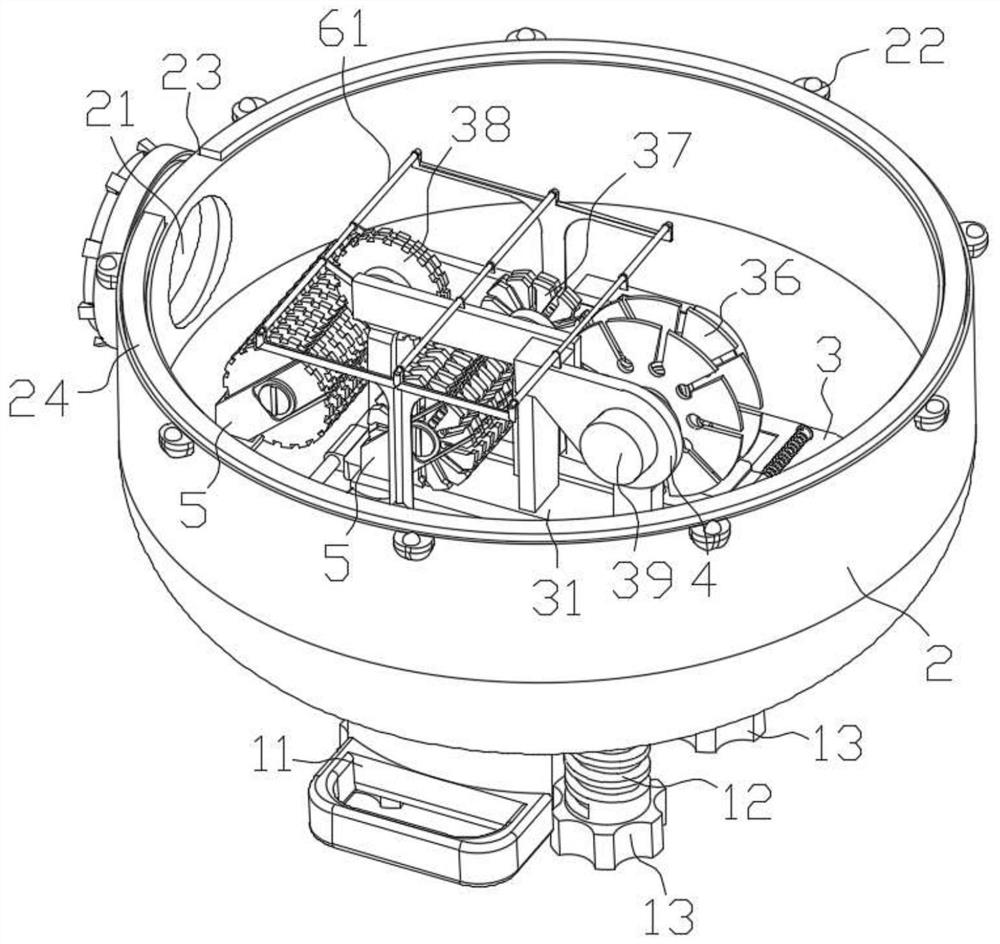

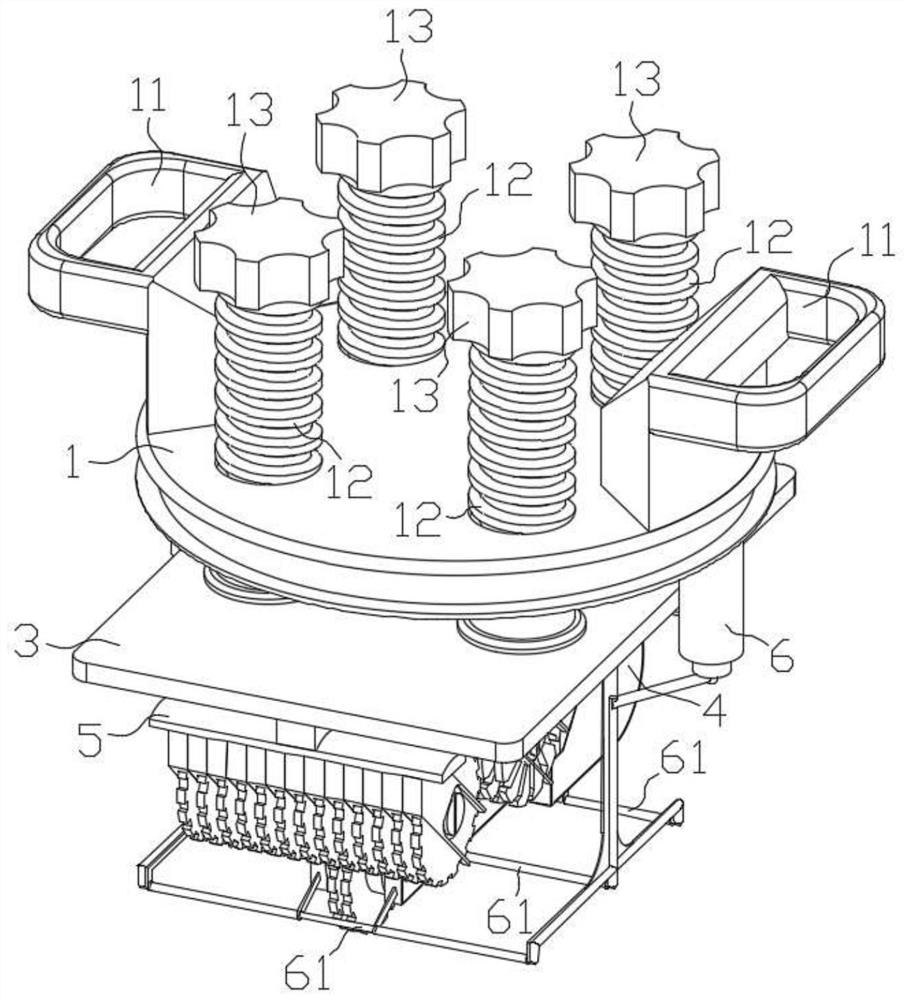

[0041] like figure 1 , 2 . As shown in 3, a wall ditching and cutting device for building engineering construction includes: a device main body, which includes a central carrier 1 and an annular casing 2, the annular casing 2 is rotationally connected with the central carrier 1, and the annular casing 2. The bottom surface is provided with an outlet 21 for slag discharge of the external charging bag. The four corners of the inner side of the cutting tool holder 3 are respectively provided with an adjusting screw 12 for limiting the height. The adjusting screw 12 is threadedly connected with the central carrier plate 1 and passed The adjustment knob 13 on the outer surface of the center carrier 1 is controlled. By setting the adjusting nut 12, the cutting depth of the cutter holder 3 can be effectively and quickly adjusted, and the control is simple and effective. There are two groups of handles 11 arranged symmetrically and parallelly on the outer surface of the central carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com