Indentation device

A technology of indentation and indentation knife, which is applied in the direction of packaging, transportation and packaging, paper/cardboard containers, etc., and can solve the long production cycle of trademark paper or carton paper indentation knife board, prolong the cycle of new products, and the production of knife board Problems such as high cost, to achieve the effect of adjustable indentation line size, excellent creasing performance, and shortened cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

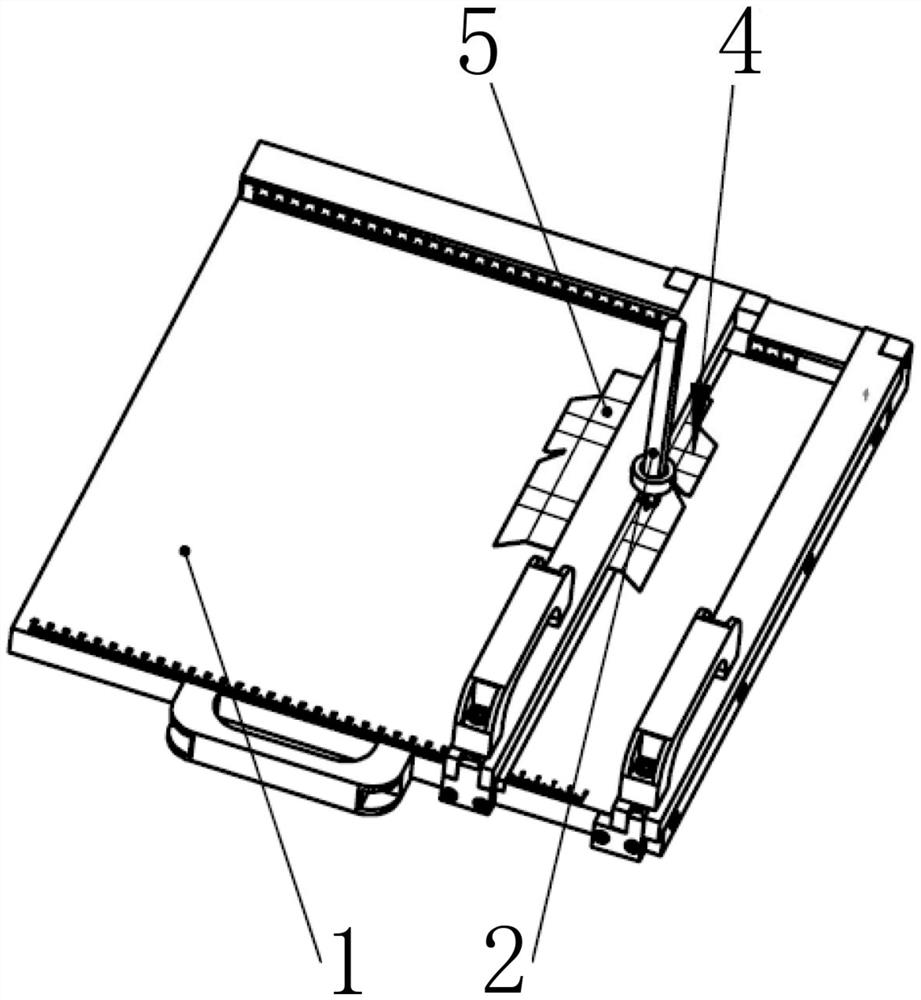

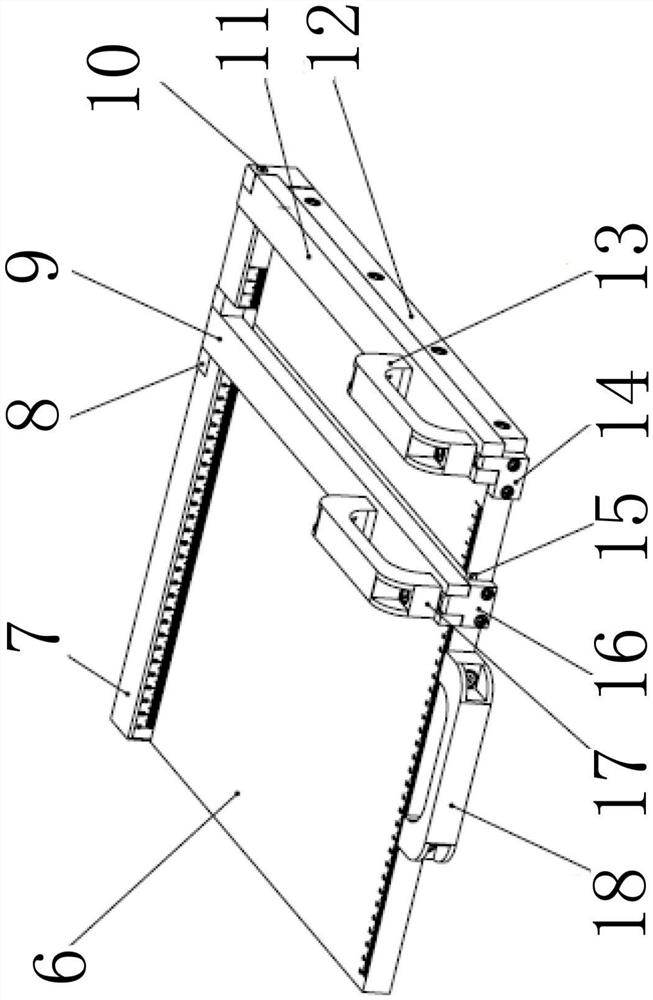

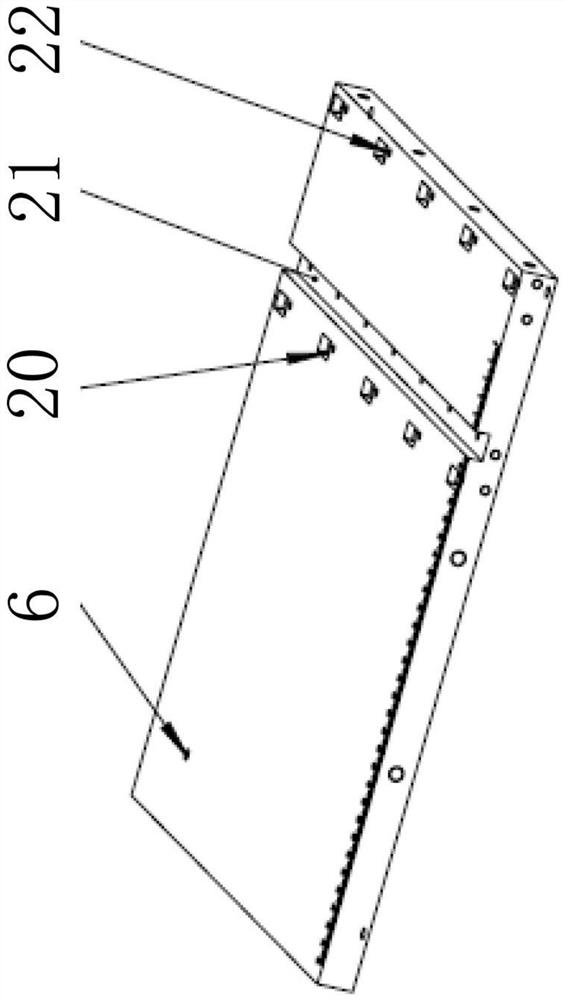

[0047] figure 1 It is a schematic diagram of the working state of the indentation device in Example 1 of the present invention. figure 2 It is a schematic diagram of the assembly structure of the indentation device in Example 1 of the present invention. Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an indentation device, which includes a positioning bottom plate 6, a positioning seat 7, a left pressing plate 9, an indentation pad 15 and an indentation knife. The left pressing plate 9 is hinged with the positioning seat 7, and the positioning seat 7 is fixedly connected with the positioning base plate 6. The positioning base plate 6 is provided with a long groove 21, and the indentation pad 15 is arranged in the long groove 21, and the left pressing plate 9 is located at the indentation pad 15 above. The creasing device is suitable for manual creasing operation of cigarette label paper and carton paper in the development of new c...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 lies in that the indentation pad 5 is clamped in the long groove 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com