Automatic filling, weighing and packaging sample collector

A technology of automatic filling and sample collecting device, which is applied to electric operation devices, opening closed containers, packaging, etc. It can solve the problems of manual sampling, weighing and sealing interference, and achieve the effect of avoiding sample mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

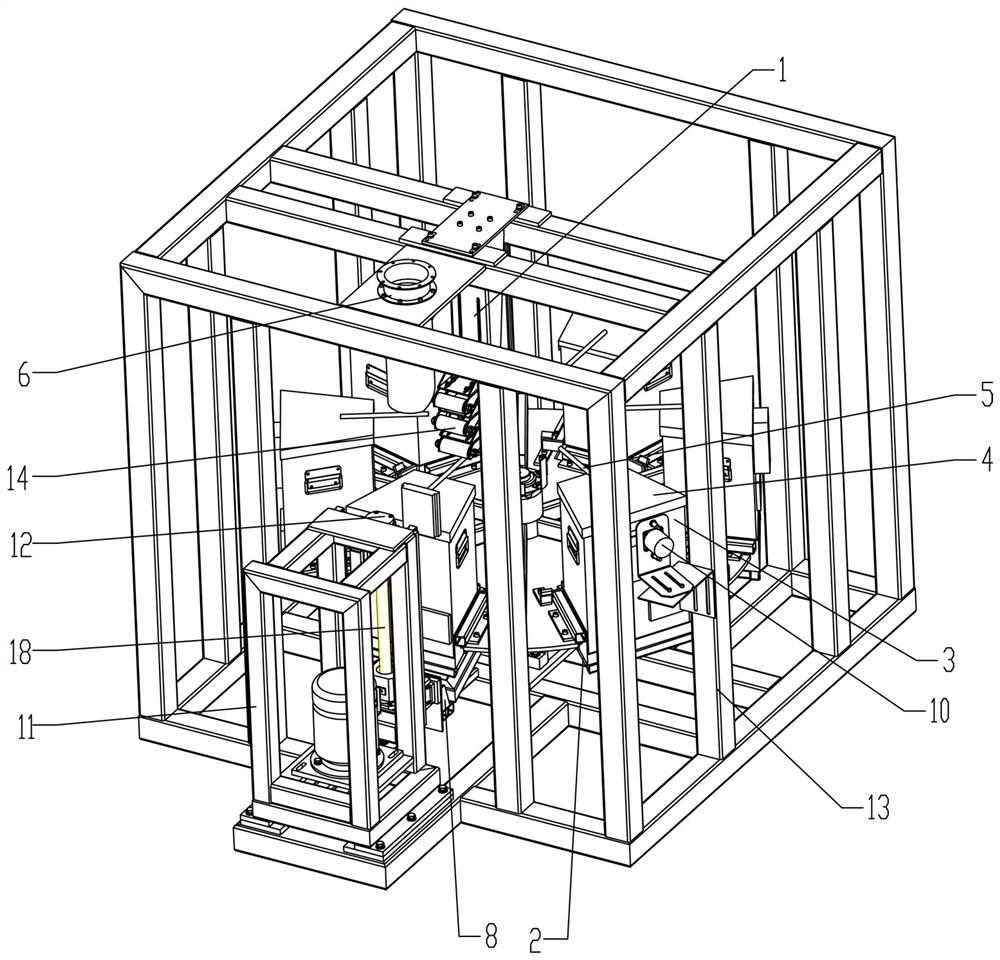

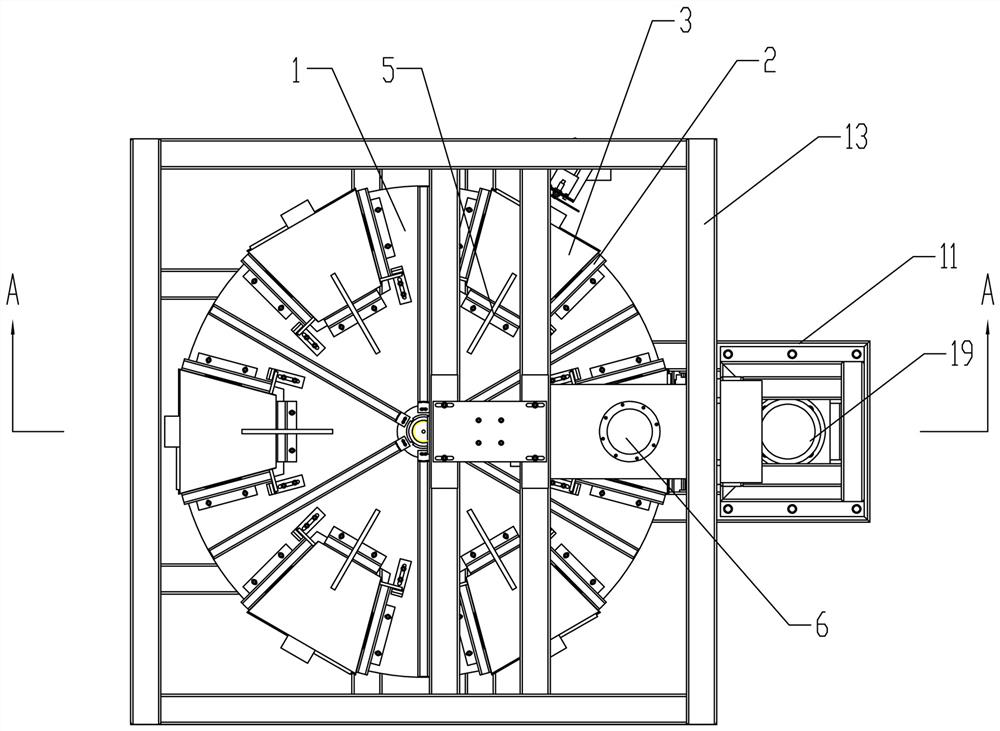

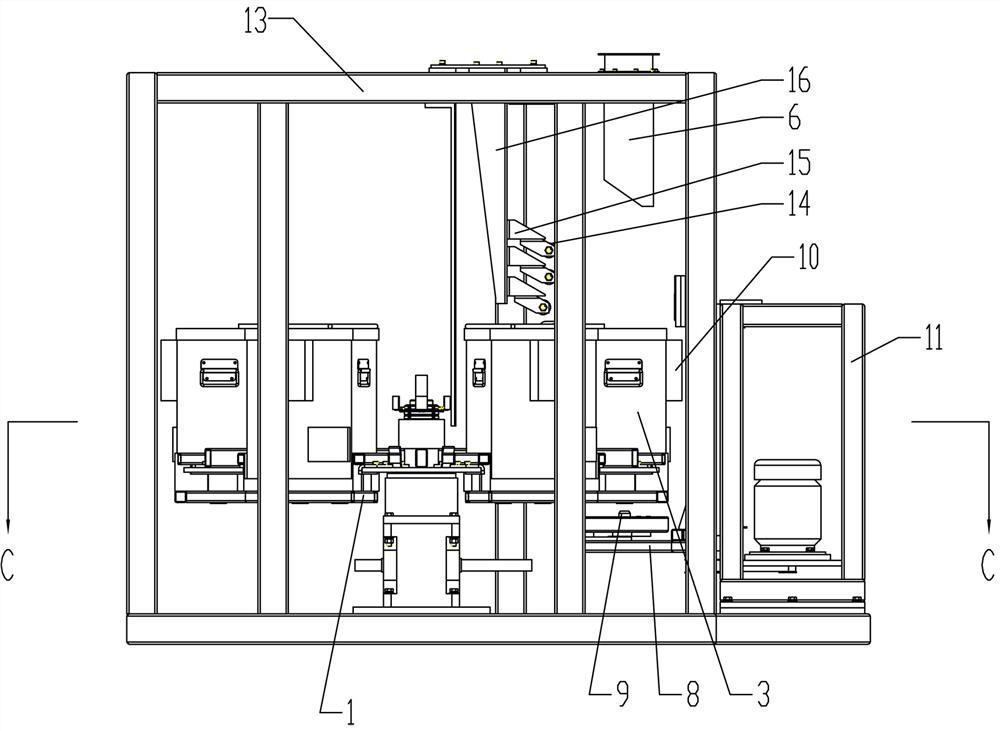

[0027] The specific structure of the present invention is further described below:

[0028] The automatic filling, weighing and packaging sample collector of the present invention has a structure such as Figure 1-6 As shown in the figure, it includes a rotating disc 1 with a divider in the middle, and a plurality of brackets 2 are arranged on the edge of the rotating disc 1 at equal angles. . A coal drop pipe is fixedly arranged above one of the sample collection barrels 3, and the bracket at this position is used as a filling station. The isolation frame frames the rotating disc 1 and the filling cylinder 6 inside, forming a physical isolation between the rotating disc and the filling position and the outside.

[0029] The top bung 4 edges of the sample collection bucket 3 are hinged on the sample collection bucket 3, the bung 4 is provided with an uncap lever 5, and an electronic lock 10 is arranged between the bung 4 of the sample collection bucket 3 and the bung 4 side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com