Wastewater treatment equipment for textile fabric printing and dyeing

A technology for wastewater treatment and textile fabrics, which is applied in the textile industry wastewater treatment, water/sewage treatment equipment, multi-stage water treatment, etc. The effect of improving the strength, increasing the adsorption capacity and improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

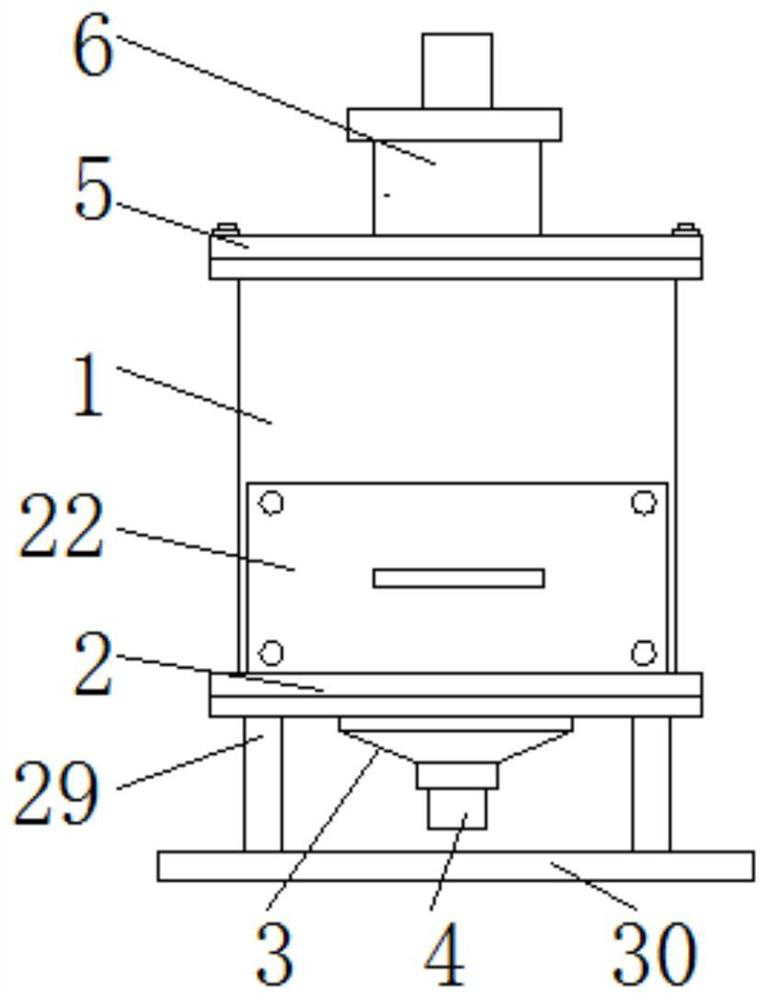

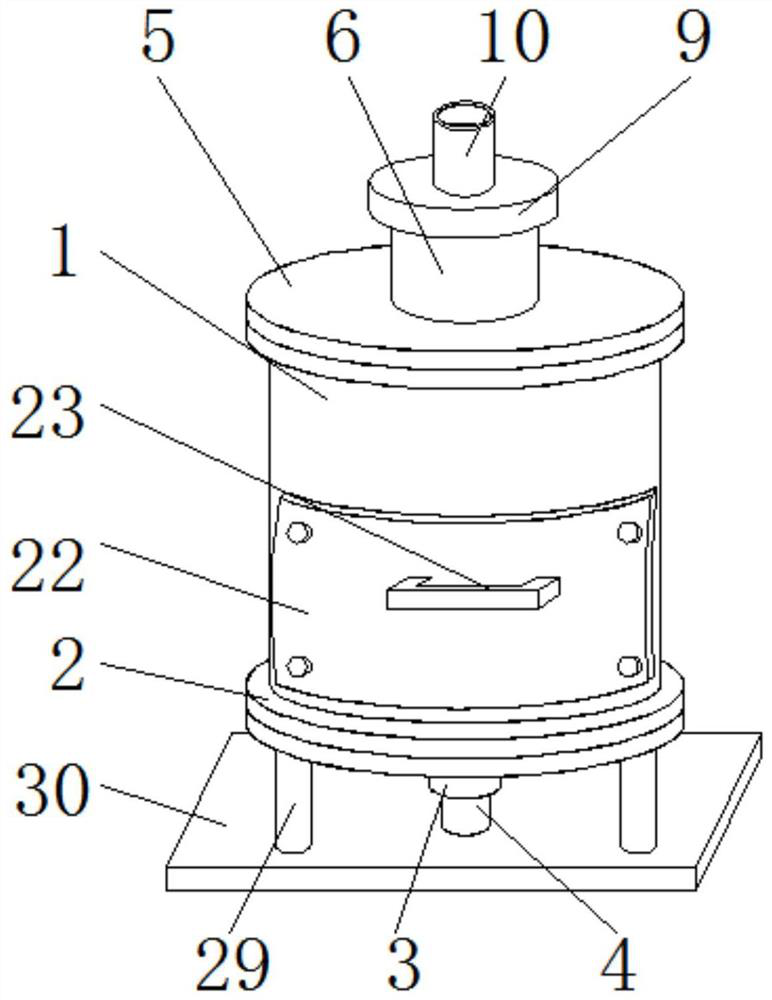

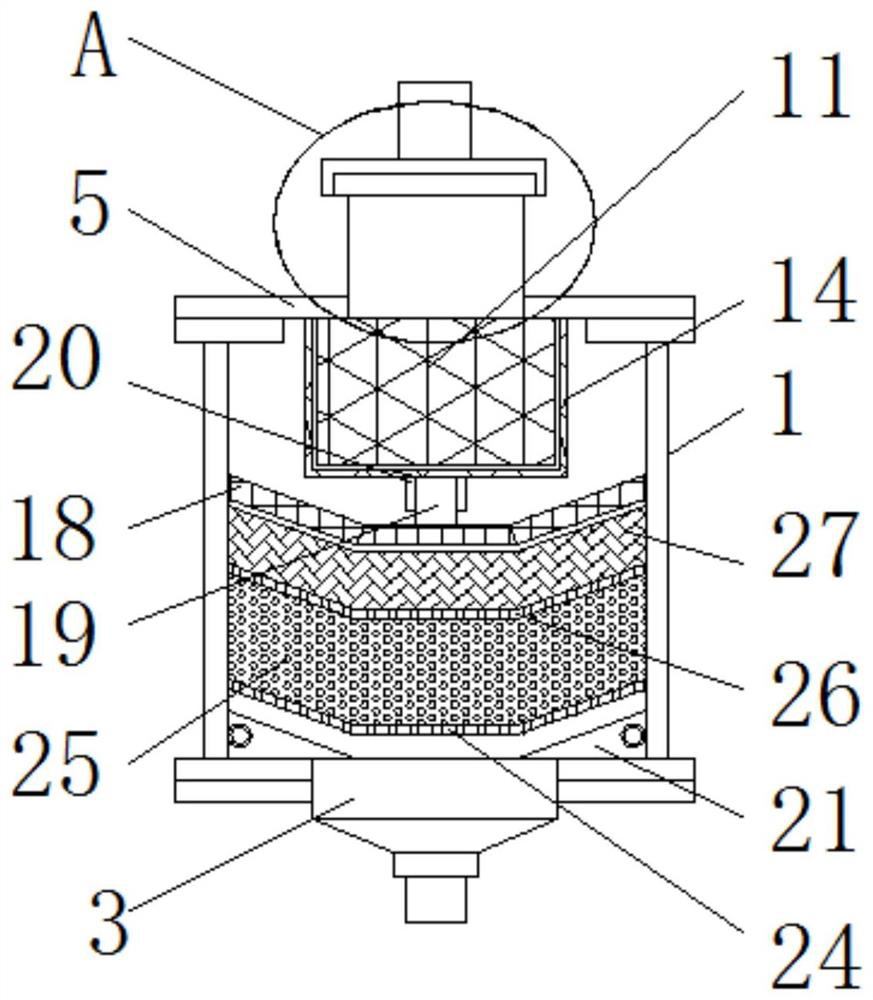

[0036] see Figure 1-7, the present invention provides a kind of wastewater treatment equipment for printing and dyeing of textile fabrics, comprising a casing 1, the top and bottom of the casing 1 are hollow structures, and the lower surface of the casing 1 is fixedly installed with a base 2, and the upper surface of the casing 1 A top plate 5 is installed movable, and a sleeve 6 is vertically welded between the upper and lower surfaces of the top plate 5. The upper end of the sleeve 6 is vertically slid to install a base plate 7, and the middle position of the lower surface of the base plate 7 is fixedly installed with a spiral type Conduit 8, a liquid bucket 3 is welded between the upper and lower surfaces of the base 2, the bottom of the liquid bucket 3 is fixedly installed with a drain pipe 4, and the drain pipe 4 and the base 2 are vertically arranged, and the spiral conduit 8 is slidably installed on the sleeve 6 and the upper end of the spiral conduit 8 is vertically f...

Embodiment 2

[0038] see Figure 2-8 , the present invention provides a kind of wastewater treatment equipment for printing and dyeing of textile fabrics, comprising a casing 1, the top and bottom of the casing 1 are hollow structures, and the lower surface of the casing 1 is fixedly installed with a base 2, and the upper surface of the casing 1 A top plate 5 is installed movable, and a sleeve 6 is vertically welded between the upper and lower surfaces of the top plate 5. The upper end of the sleeve 6 is vertically slid to install a base plate 7, and the middle position of the lower surface of the base plate 7 is fixedly installed with a spiral type Conduit 8, a liquid bucket 3 is welded between the upper and lower surfaces of the base 2, the bottom of the liquid bucket 3 is fixedly installed with a drain pipe 4, and the drain pipe 4 and the base 2 are vertically arranged, and the spiral conduit 8 is slidably installed on the sleeve 6 and the upper end of the spiral conduit 8 is vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com