Post-cast strip plugging structure and construction method thereof

A post-casting belt and mesh blocking technology, which is used in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problem of high randomness in construction of pure steel mesh plugging structures, swelling and leakage of concrete pouring, and the formation of cross-section perception. Poor quality and other problems, to achieve the effect of scientific construction method, smooth spreading and simple cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

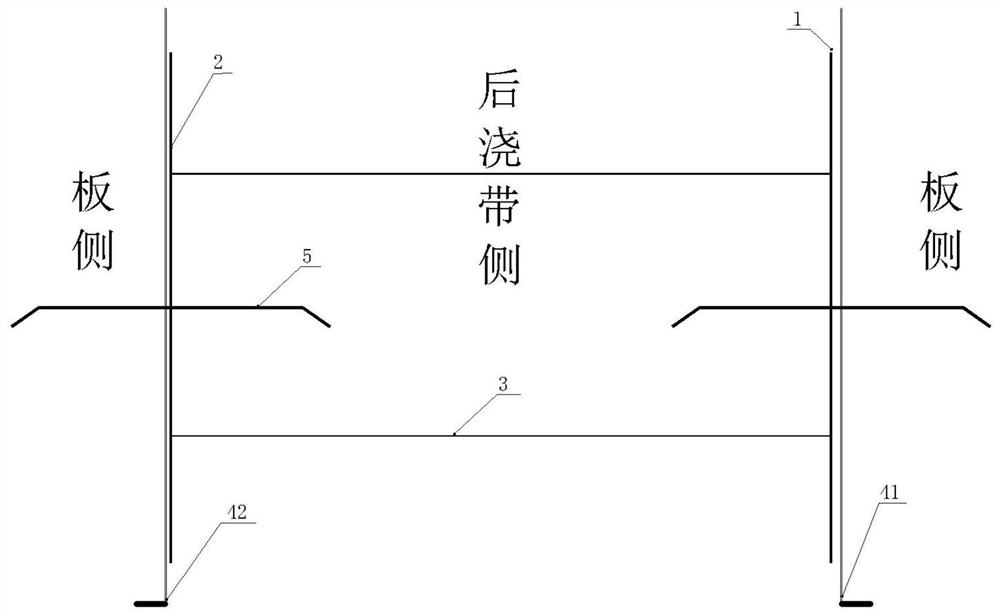

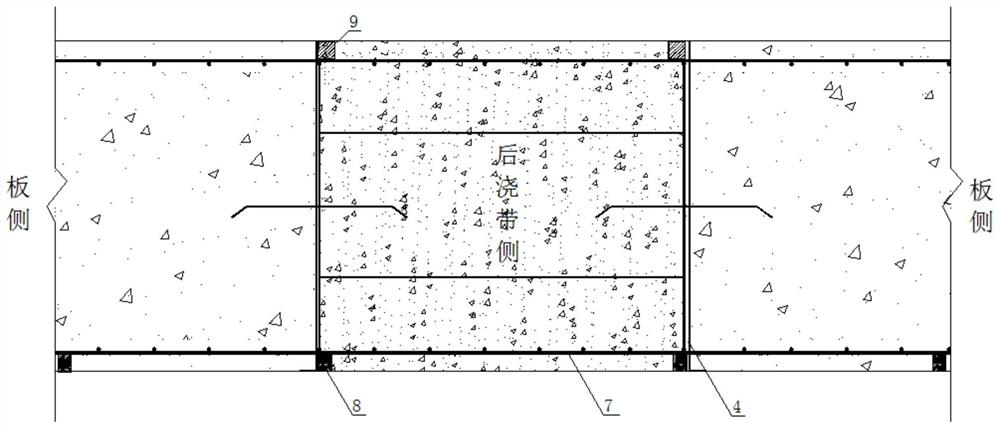

[0044] figure 1 , figure 2 The post-cast tape sealing structure provided by the present invention is shown. The post-casting belt sealing structure includes longitudinal steel bars 1, fixed steel bars 2, supporting steel bars 3, sealing nets 4, water-stop steel plates 5 and transverse steel bars 7.

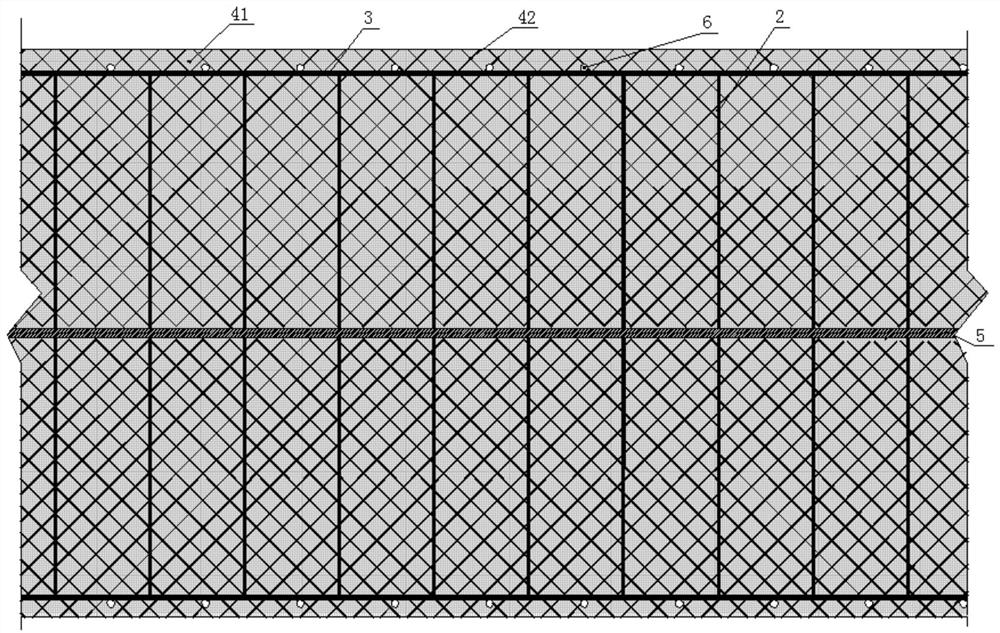

[0045] The plugging net 4 is vertically arranged at the interface between the post-cast tape side and the plate side. The plugging layer 2 is a multi-layer structure, including a glass fiber mesh layer 41 and a gauze layer 42; wherein the glass fiber mesh layer 41 is arranged on the side of the post-casting tape, and the gauze layer 42 is arranged on the side of the plate. The mesh size of the glass fiber mesh cloth layer is 4mm*4mm. The gauze layer is 1-2 layers, glued to the glass fiber mesh cloth layer.

[0046] The water-stop steel plate 5 is horizontally arranged in the middle of the plugging net 4, and penetrates from the inside of the plate side to the inside of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com