Integrated self-cleaning insect-expelling electrical cabinet

A self-cleaning, electrical cabinet technology, applied to electrical components, animal repellants, substation/power distribution device shells, etc., can solve problems affecting the heat dissipation of electrical cabinets, and achieve the effect of improving the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

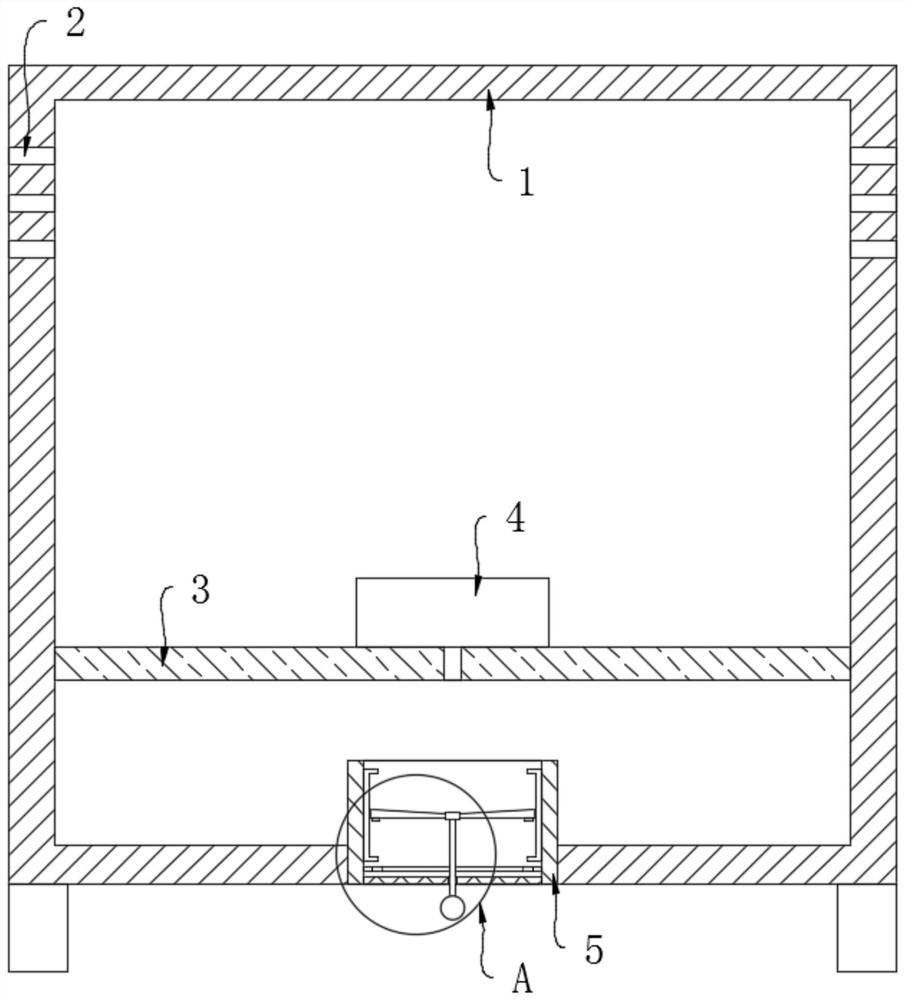

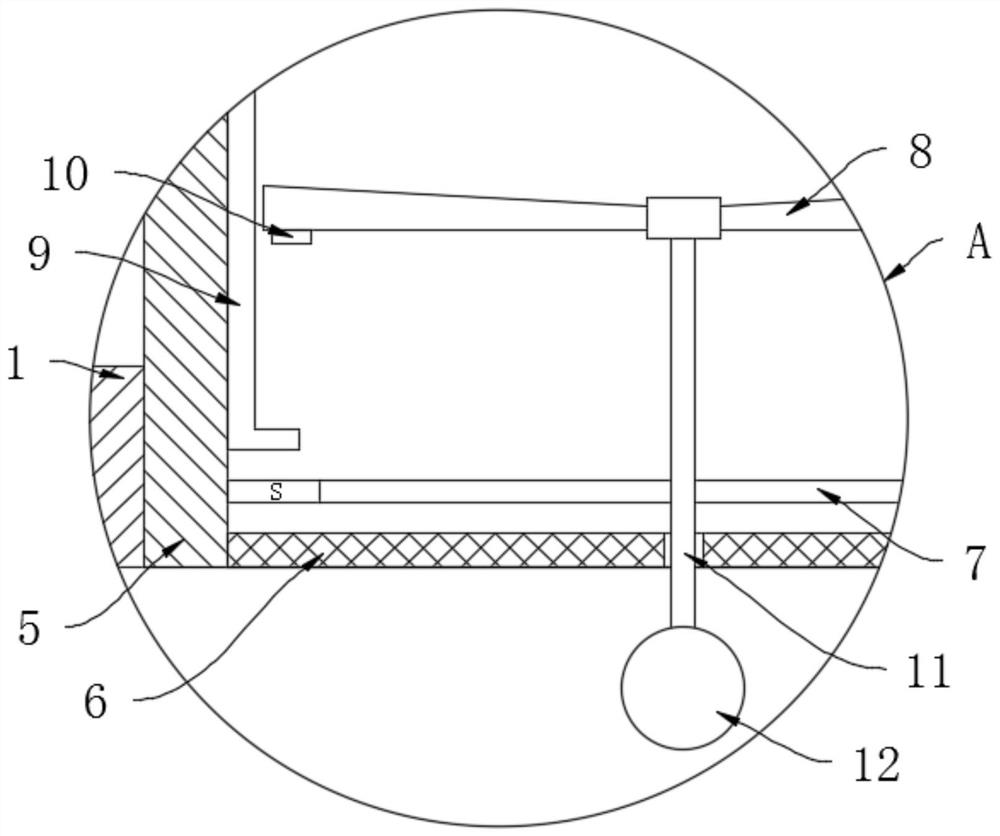

[0023] refer to Figure 1-3 , an integrated self-cleaning insect repellent electrical cabinet, including a cabinet body 1, the interior of the cabinet body 1 is divided into an installation area and a circulation area by a horizontally fixed partition 3, and the installation area is located above the circulation area, and the installation area is used for To install electrical equipment, the upper end of the side wall of the cabinet body 1 is symmetrically opened with a plurality of vents 2 connecting the installation area with the outside world, and the fan 4 is arranged on the partition 3, and the output and input ends of the fan 4 pass through the conduit and the installation area respectively. Connected with the circulation area;

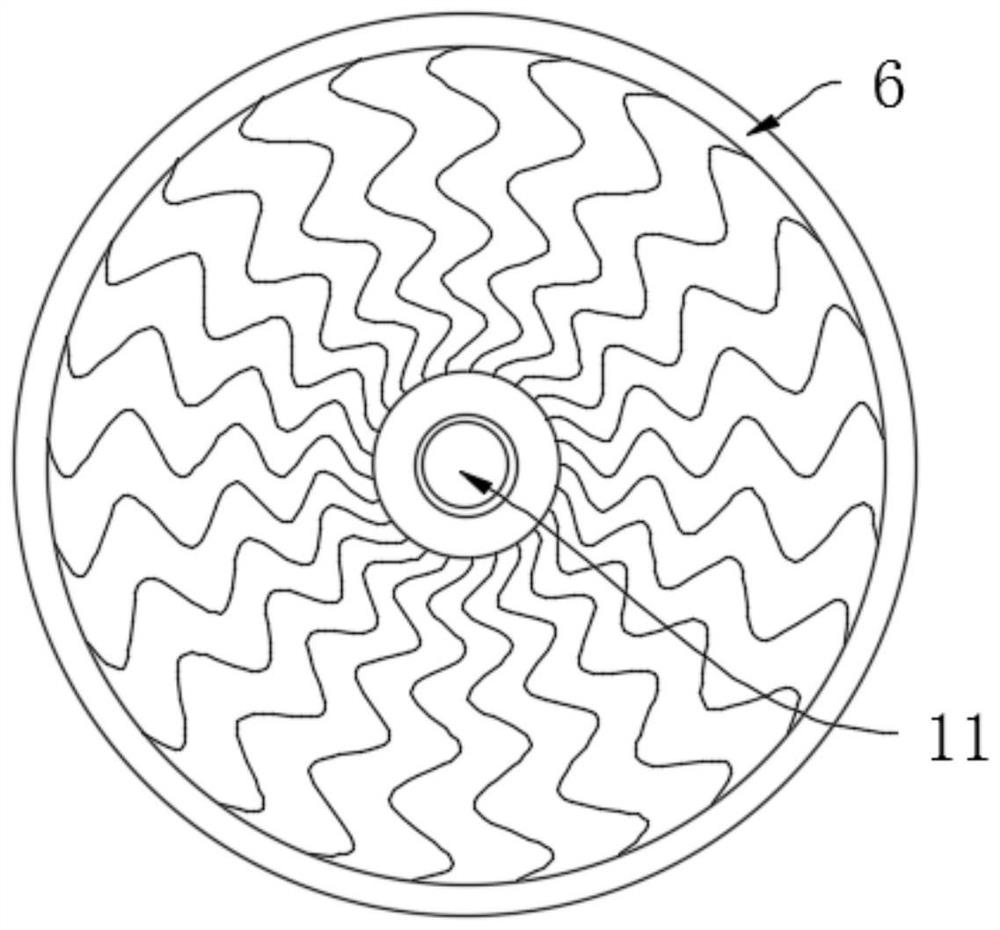

[0024] There is a circular through hole in the middle of the lower end surface of the cabinet body 1, and a vertical pipe 5 is fixedly inserted in the through hole, and the upper end of the vertical pipe 5 is directly opposite to the input end o...

Embodiment 2

[0028] refer to Figure 4-5 , the present embodiment differs from Embodiment 1 in that: a plurality of liquid storage boxes 13 are symmetrically and fixedly connected to the lower end surface of the partition plate 3, and the plurality of liquid storage boxes 13 are distributed around the upper end of the vertical pipe 5, each The lower end surfaces of the liquid storage boxes 13 are all symmetrically provided with water guide holes, and each water guide hole is fixedly connected with a water absorbing strip 14, and the corresponding two water absorbing bars 14 are jointly elastically connected with a vibrating plate made of a ferromagnetic material. Spring 15, the surface of vibrating spring 15 is fixedly connected with water-absorbing velvet, and water-absorbing velvet and water-absorbing bar 14 all adopt polymer water-absorbing resin to make, and the hydrophilic group that its structure has, endows it extremely strong water-absorbing property, to guarantee The water on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com