Tea cleaning equipment

A technology for cleaning equipment and tea leaves, applied to lighting and heating equipment, tea treatment before extraction, cleaning methods and utensils, etc., can solve problems such as low efficiency and waste of time, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

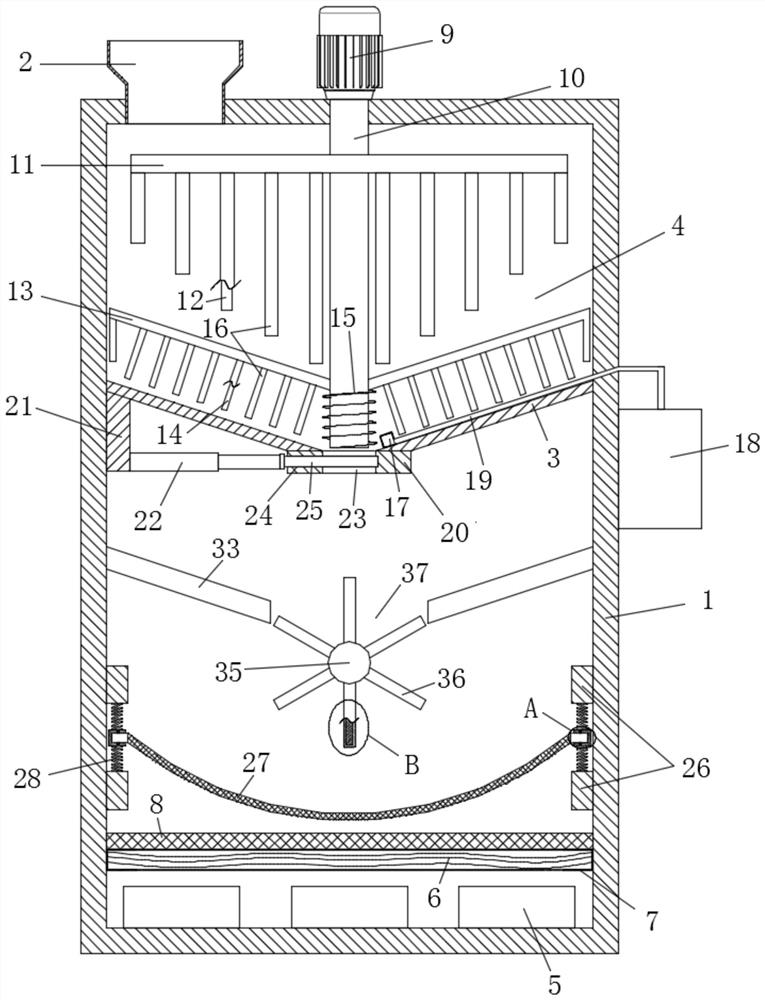

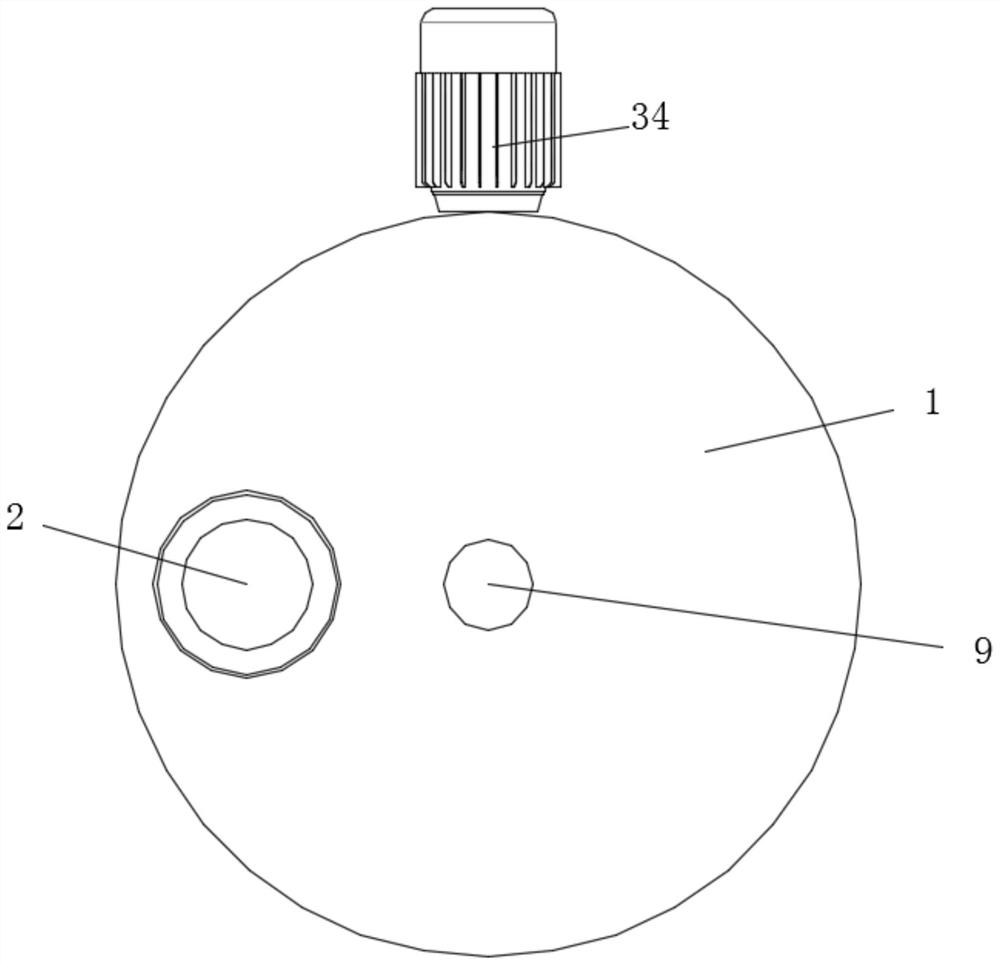

[0022] see Figure 1-4 , a kind of tea cleaning equipment, including a cleaning box 1, a feeding hopper 2 and a cleaning assembly, the feeding hopper 2 is arranged on the top of the cleaning box 1, and the cleaning assembly is arranged above the inside of the cleaning box 1, the The inner wall of the side of the cleaning box 1 is fixedly installed with a partition 3 formed integrally with it. The partition 3 is in the shape of a "V". The bottom of the partition 3 is provided with a dynamic sealing valve assembly. The partition 3 and the cleaning box 1 to form a cleaning chamber 4, a drainage assembly is arranged below the partition 3 in the cleaning chamber 4, a drying assembly is arranged at the bottom of the cleaning box 1, and a tea drying and placement assembly is arranged above the drying assembly The drying assembly includes a number of blowers 5 evenly arranged at the bottom of the cleaning box 1, a number of electric heating wires 6 above the blower 5, and an open inst...

Embodiment 2

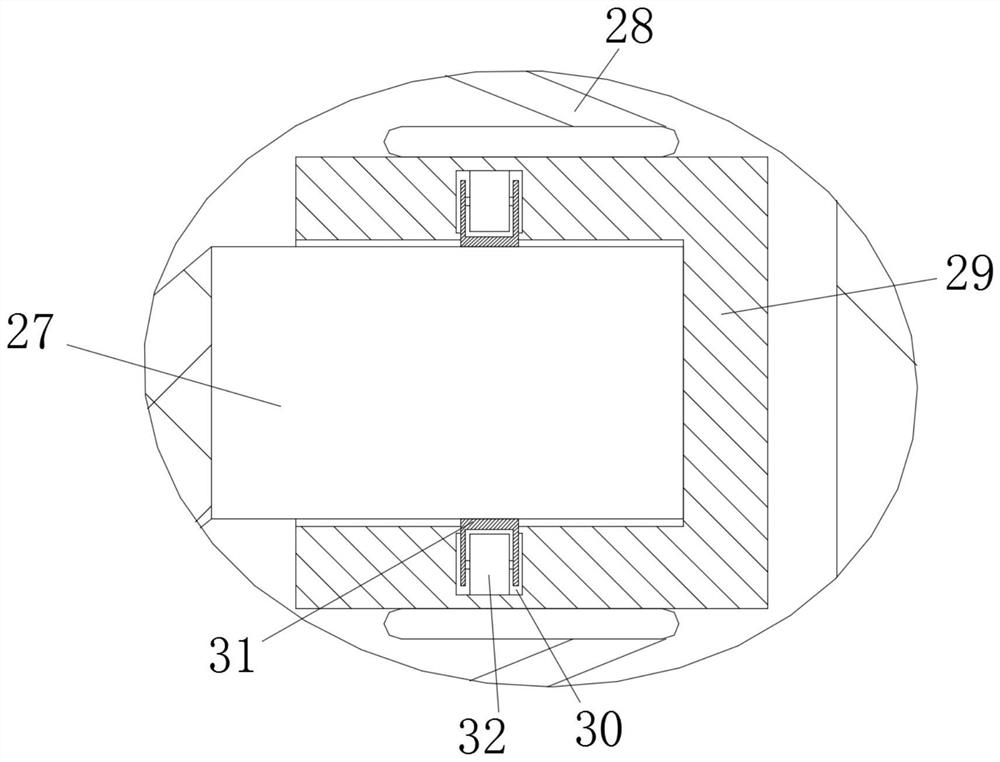

[0030] This embodiment is further improved on the basis of the embodiment, and the improvement is that: a component blanking assembly is set between the tea storage grid trough 27 and the partition plate 3, and the side inner wall of the cleaning box 1 is fixedly installed and integrally formed with it The hollowed-out inclined-plane partition 33 in the middle, the component blanking assembly is located below the middle of the inclined-plane partition 33, and the component blanking assembly includes a component blanking motor 34 fixedly installed on the outer wall of the cleaning box 1, so The output end of the component blanking motor 34 is fixedly installed with a component blanking rotating shaft 35, and the component blanking rotating shaft 35 is rotatably installed on the cleaning box 1, and the component blanking rotating shaft 35 is evenly arranged with several component hollow partitions along the circumferential direction 36, a component groove 37 is formed adjacent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com