Multifunctional grinding medium producing and processing equipment

A technology for grinding media and processing equipment, applied in the field of grinding media production and processing equipment, can solve the problems of inconvenient heat of castings, inconvenient collection, and inconvenience in taking workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

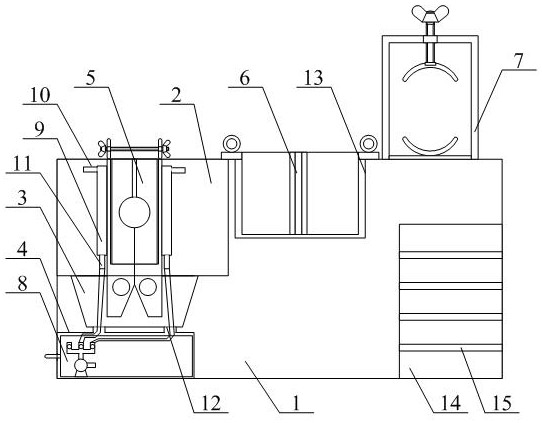

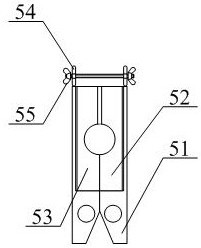

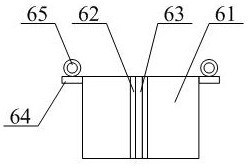

[0036] The present invention will be described in detail below in conjunction with the drawings, as attached figure 1 And figure 2 As shown, the multifunctional grinding media production and processing equipment includes a processing table 1, a casting cavity 2, a fixed groove 3, an insertion groove 4, a rotatable insertion casting seat structure 5, a temperature-insulating liquid cooling box structure 6, and a rotatable Fixed grinding frame structure 7, recyclable collection box structure 8, recovery box 9, return water pipe 10, water inlet pipe 11, recovery hole 12, insertion hole 13, storage cavity 14 and placement plate 15, said casting cavity 2 is opened In the middle position of the inner left side of the upper end of the processing table 1; the fixed groove 3 is opened in the middle position of the inner bottom end of the casting cavity 2; the insertion groove 4 is opened in the lower left side of the processing table 1; The rotatable plug-in casting seat structure 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com