Cutting device for production of heat insulation strips

A technology of cutting device and heat insulation strip, applied in metal processing and other directions, can solve the problems of low accuracy, time-consuming and laborious, troublesome operation, etc., and achieve the effects of high accuracy, high operation efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

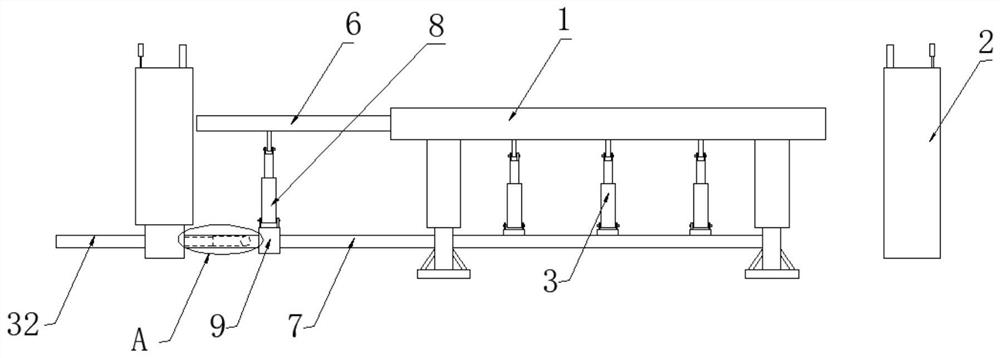

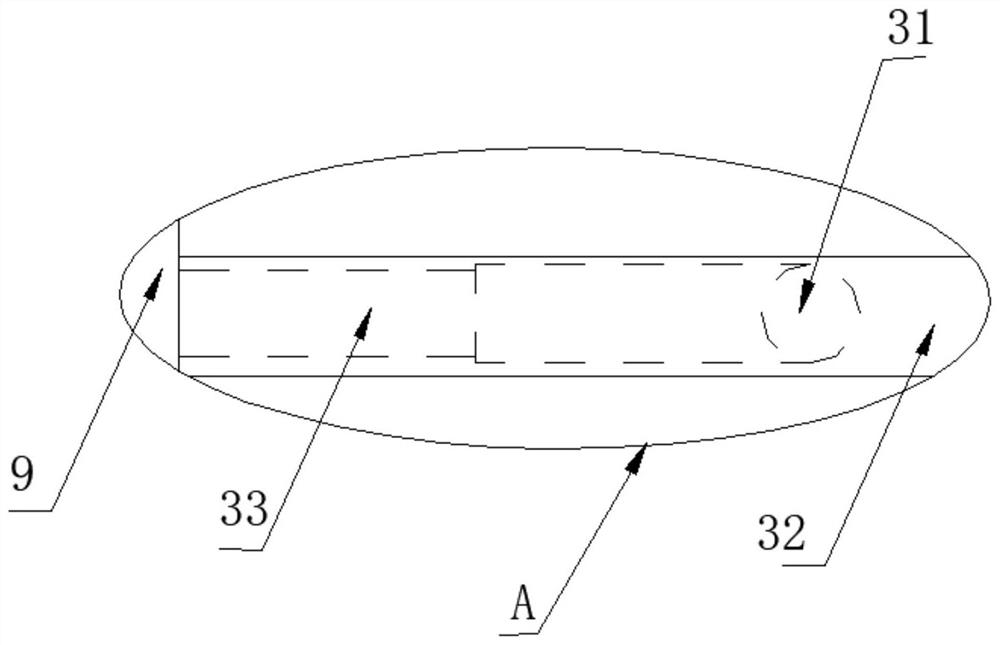

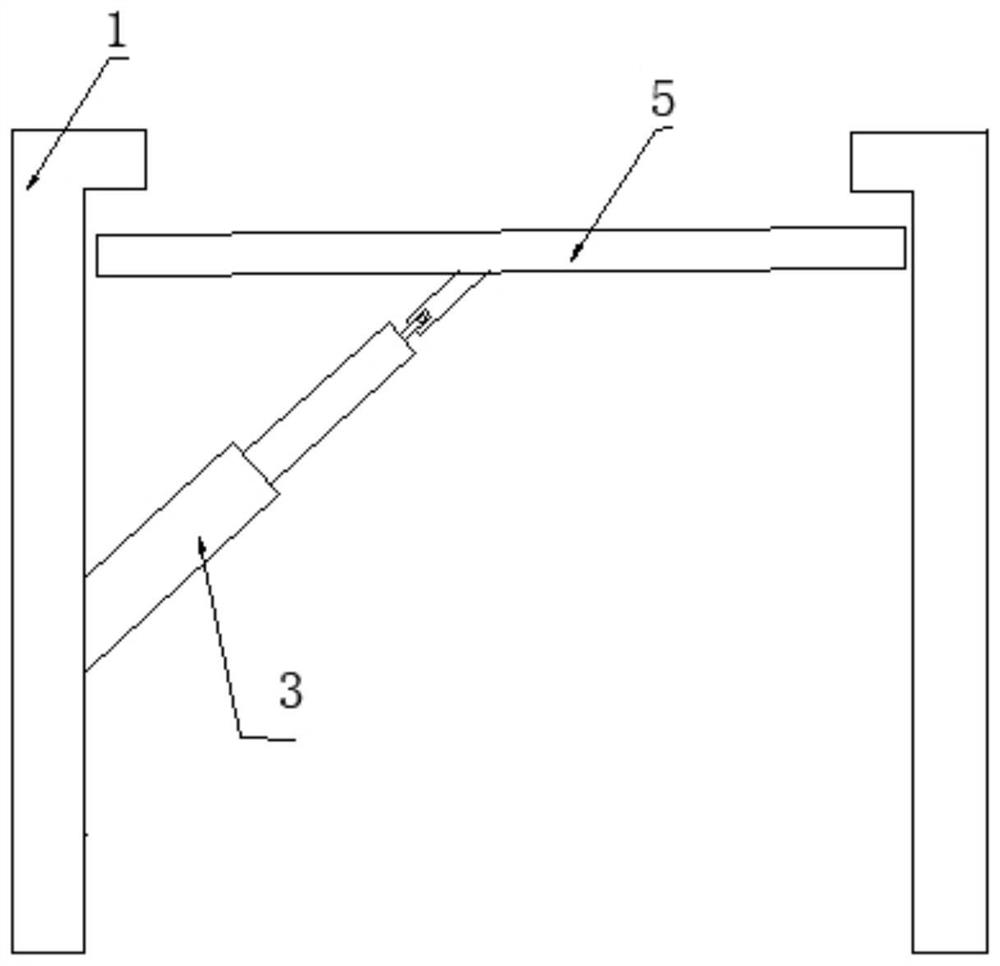

[0030] Such as Figure 1-9 As shown, a cutting device for heat insulation strip production includes a workbench 1 and two cabinets 2 located at both ends of the workbench 1. The top of the workbench 1 is rotated by a first movable mechanism to be provided with a folding plate 5, which is folded One end of the plate 5 is movably socketed with a fixed plate 6, and the bottom end of the workbench 1 is also provided with a second movable mechanism for assisting the fixing plate 6 to turn over. One end of the fixed plate 6 corresponds to one of the cabinets 2, and the cabinet body The inside of 2 is provided with a cutting system for cutting the heat insulation strips, and the cabinet body 2 corresponding to the fixed plate 6 is movably arranged on one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com